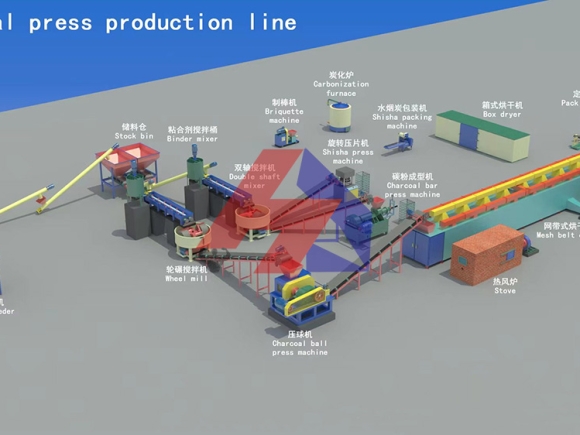

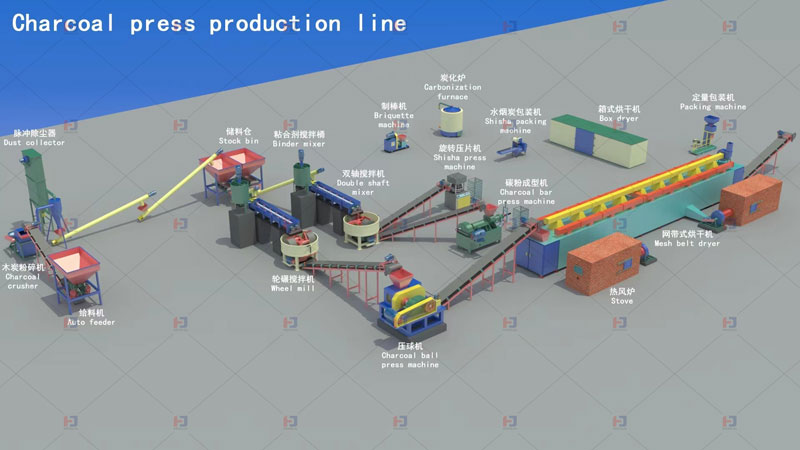

Production line process

The raw materials are first crushed by the crusher, and then enter the storage bin through the conveyor and enter the mixer for mixing. After mixing, press it into balls through a ball press. Dry through mesh belt dryer. At the same time, it can also be transported to the tablet press after mixing. Proceed to the tablet press.

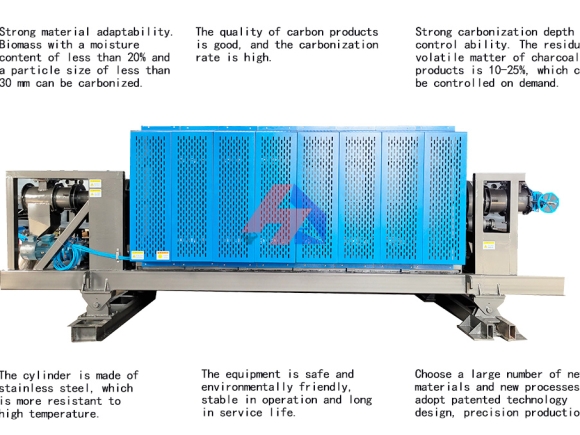

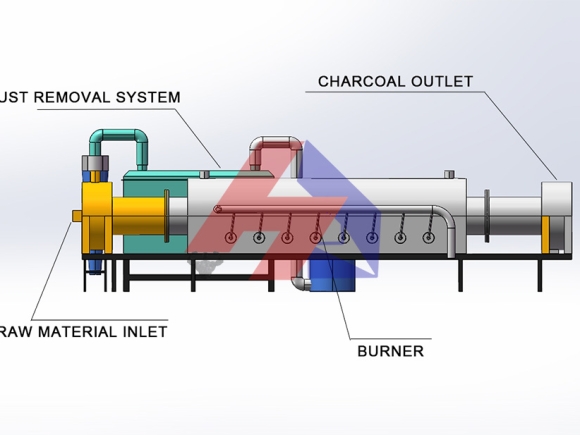

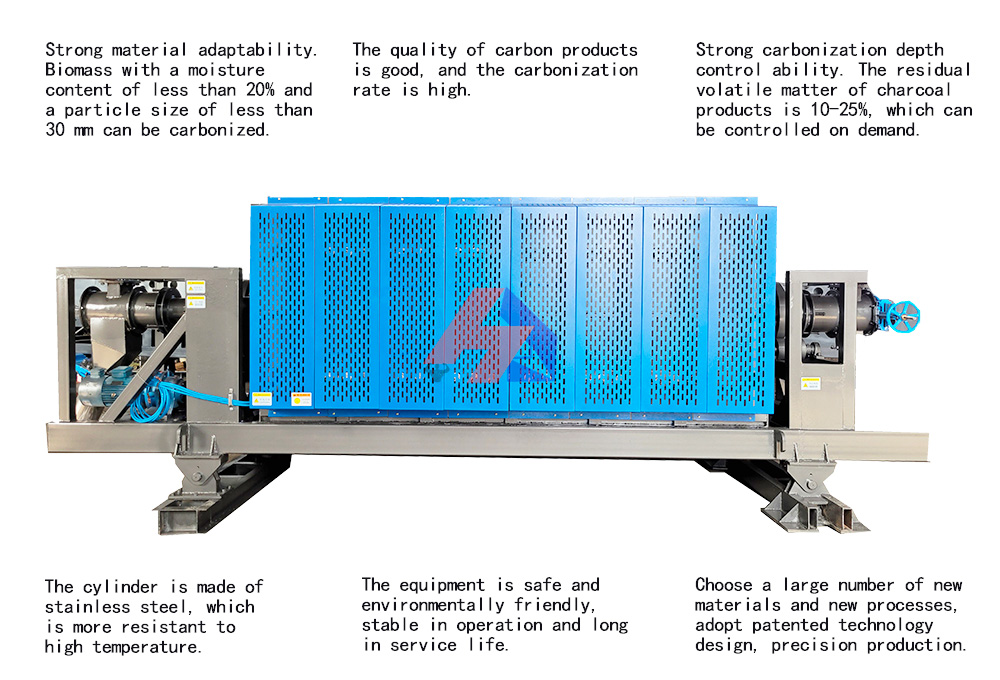

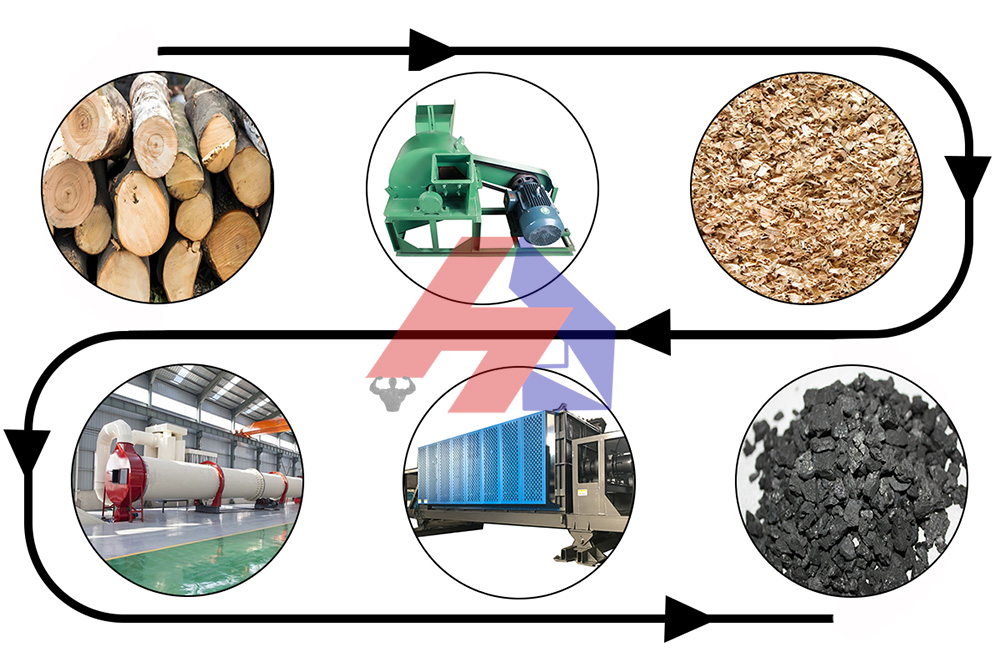

Charcoal rod making machine

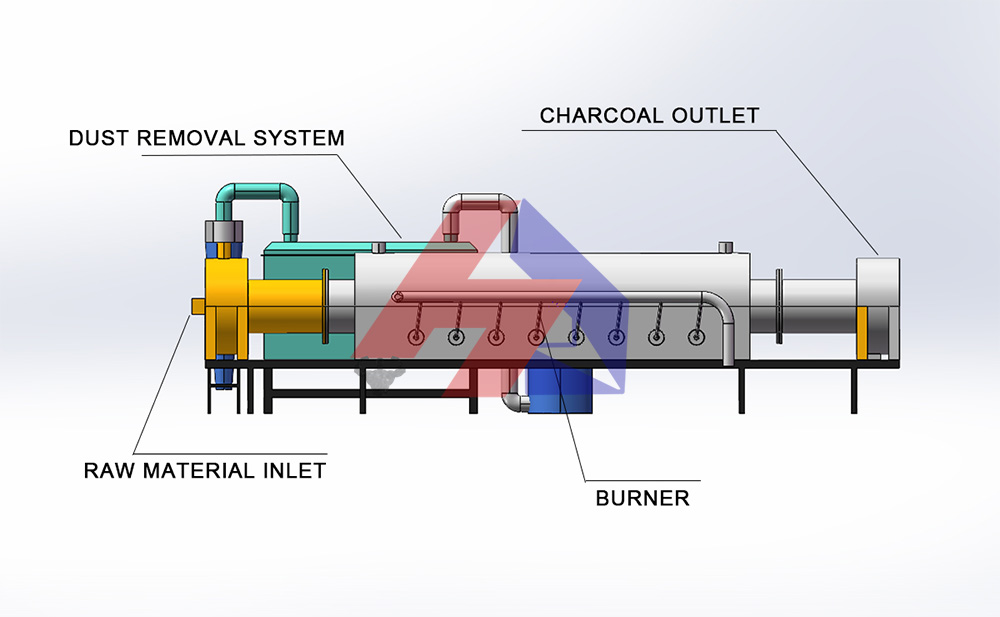

The charcoal machine is a machine that crushes the wood chips into particles within 10mm through a grinder, dry them in a dryer and then put them into a carbonization furnace for carbonization. The charcoal produced by this charcoal machine has high density, small size and good flammability, and can replace firewood and coal.

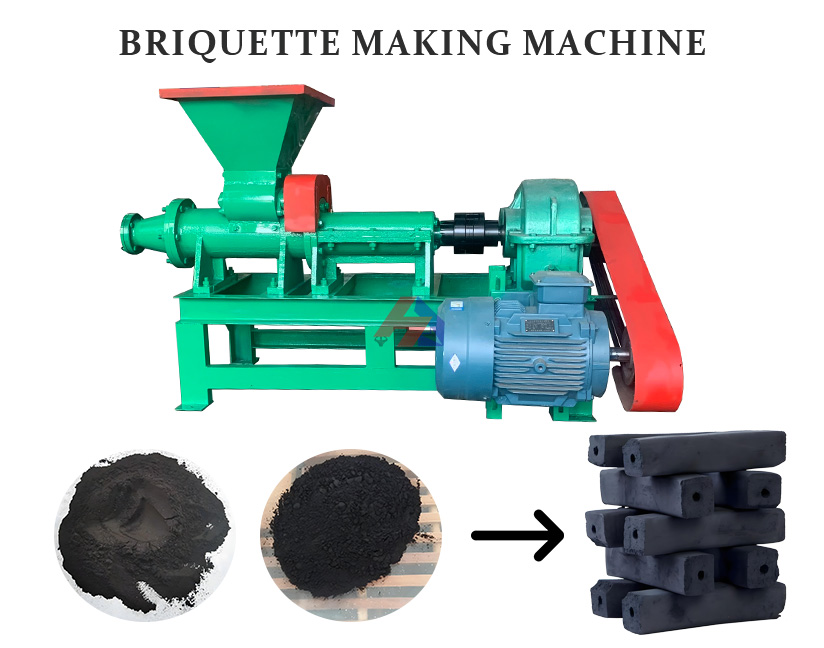

Coal rod making machine

Coal rod extruder (also called coal rod extruder) is a coal rod forming equipment that uses the principle of spiral extrusion to compress the prepared pulverized coal into a predetermined shape with a certain strength.

Coal ball press machine

The carbon powder briquetting machine is mainly used to press powdery materials that are difficult to form. It is characterized by high forming pressure, adjustable main engine speed, and equipped with a spiral feeding device.