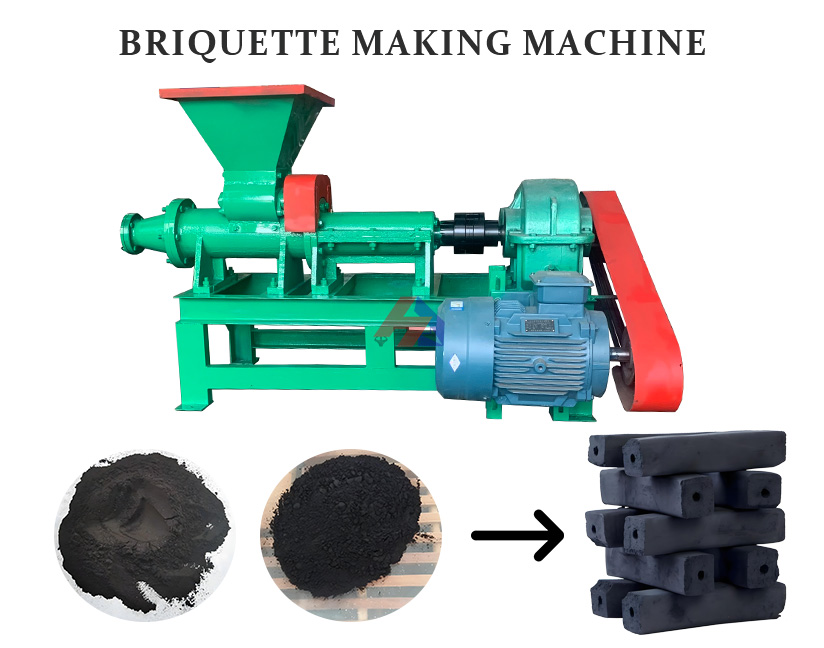

Coal rod machine is also called pulverized coal rod making machine, coal rod forming machine, coal rod extruder, hollow coal rod machine, etc. The coal rod machine uses the principle of spiral extrusion to compress the prepared pulverized coal into a coal rod forming equipment with a certain strength and a predetermined shape. It uses a hard tooth surface reducer with small size and high load-bearing capacity.

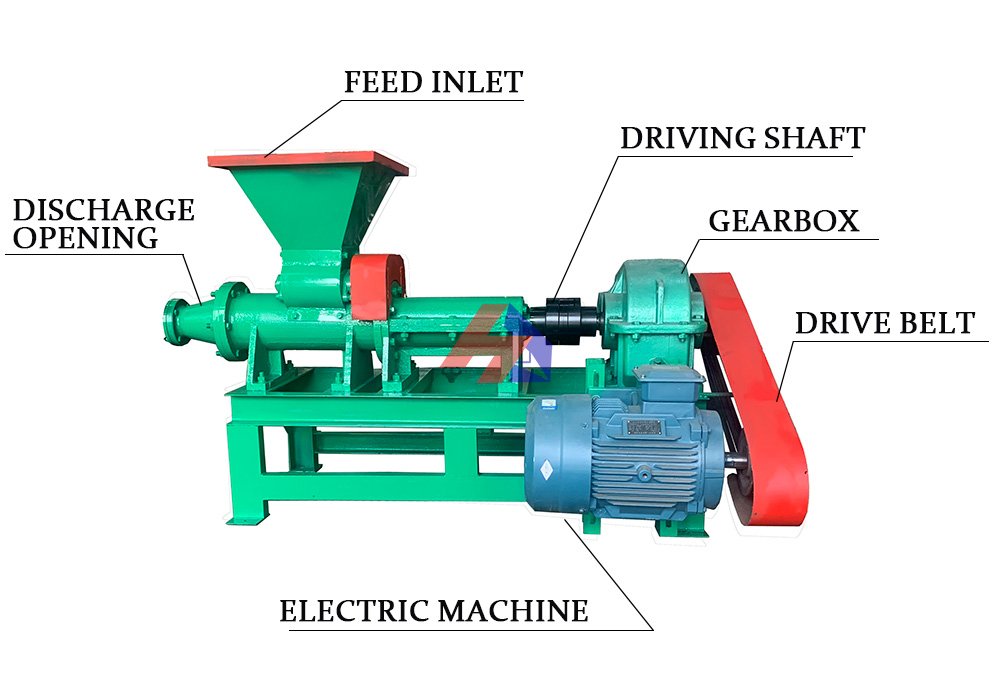

Working principle

Coal stick machine is a machine that makes powdered raw coal into strips of different shapes. Its working principle is: the electric motor transmits power to the transmission through the V-belt, and the transmission output shaft transmits the power to the propulsion shaft through the floating coupling. The propeller on the propulsion shaft pushes the coal material out through the forming die to produce the ideal coal. High pressure coal rod. Coal rod extruder, referred to as coal rod extruder, is a forming equipment that uses the principle of spiral extrusion to compress the prepared pulverized coal into coal rods with a certain strength.

Features

1. Low production cost: The coal stick machine can convert low-cost coal into efficient fuel with low production cost.

2. Easy to operate: The coal stick machine is easy to operate and does not require professional skills. It only requires simple operations to get started.

3. High production efficiency: The coal rod machine has high production efficiency and can produce a large number of coal rods in a short time.

4. Environmental protection and energy saving: The coal rods produced by the coal rod machine have high density, good combustion efficiency, reduce flue gas emissions, and meet the requirements of environmental protection and energy saving.

5. Wide application: The coal sticks produced by the coal stick machine can be widely used in barbecue, outdoor camping and other fields, and the market demand is large.

6. Safe and reliable: The coal rod machine adopts advanced production technology and materials, and has good safety and reliability.

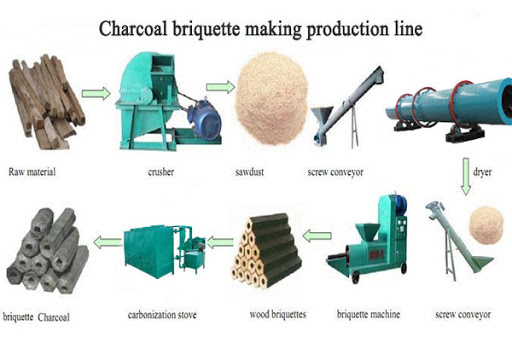

Scope of application

The coal stick machine can produce plum blossom charcoal, finger charcoal, strip charcoal and other conventional charcoal and special-shaped charcoal. It can also make different molds according to customer requirements and has a wide range of applications. It can also be used to make rods from raw materials, such as straw, sawdust, rice husks, tree bark and other combustible biomass, which can be carbonized first and then turned into charcoal powder. After crushing and stirring, rods can be formed and made into rods. This machine can be used for multiple purposes.