| ⚡ Production Revolution | ||

|---|---|---|

⏱️ | 2X Faster Production↑ 150% Output | Automated continuous operation enables 24/7 production cycles with 90% less manual intervention. Intelligent sensors maintain optimal pyrolysis conditions (±5°C) for maximum throughput. |

💰 | Smart Cost Control↓ 40% OPEX | Closed-loop energy recovery system reduces fuel consumption by 65%. Predictive maintenance algorithms cut downtime costs by 80% compared to conventional systems. |

🌟 | Premium QualityISO 17225 Certified | Precision temperature control ensures 99% carbon purity. Automated sorting system guarantees uniform charcoal size (Ø25±2mm) meeting export-grade specifications. |

Performance Comparison

Traditional Methods vs Our Modern Machines

| Metric | Traditional Methods | Our Machines | Improvement |

|---|---|---|---|

| Production Capacity | 200 kg/hour | 500 kg/hour | ↑ 150% |

| Energy Consumption | 100% | 70% | ↓ 30% |

| Labor Costs | 100% | 50% | ↓ 50% |

Charcoal Making Machine Operation Demo Video

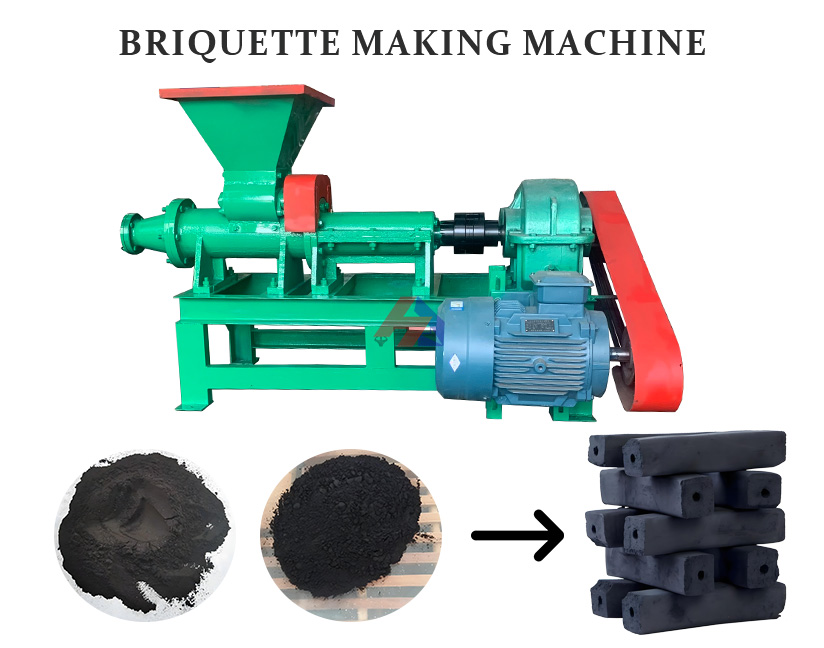

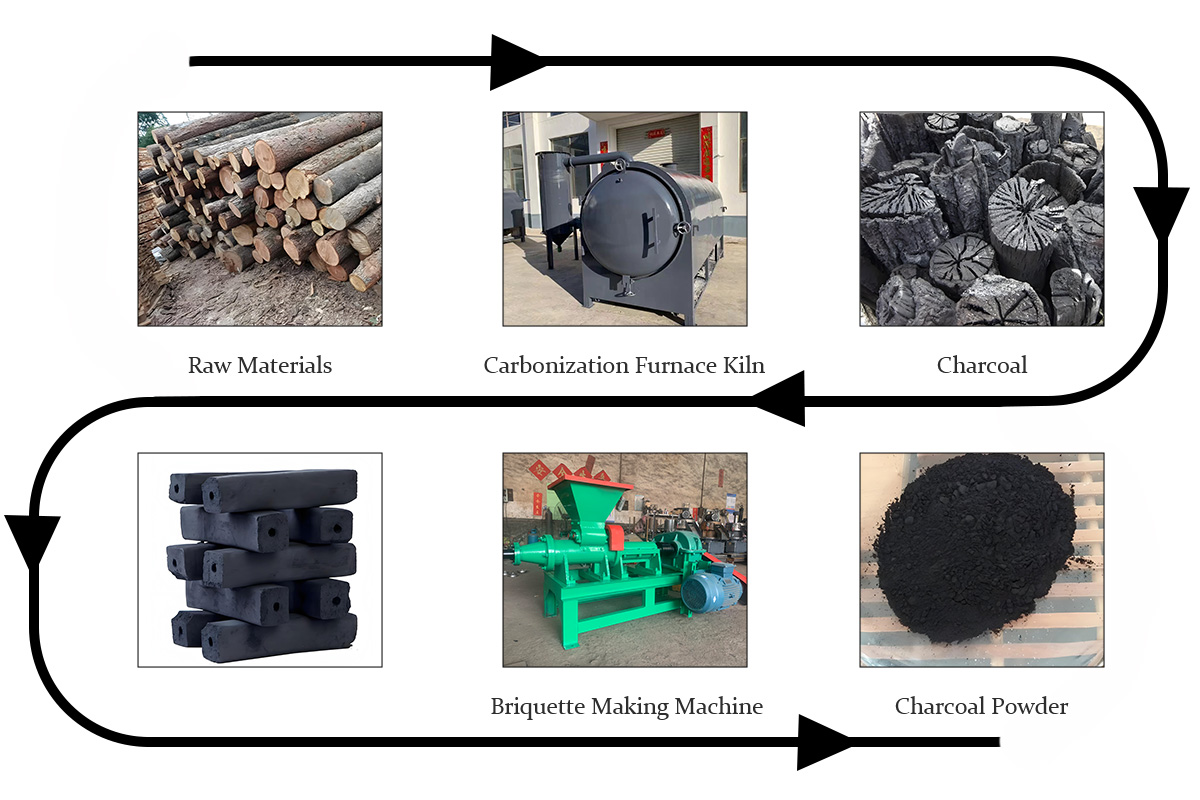

Product description

Horizontal carbonization furnace is a kind of equipment used to carbonize organic materials. It is designed in the form of horizontal layout and usually consists of carbonization chamber, heating system, exhaust system and control system.

working principle

1. Drying stage

From the start of ignition until the furnace temperature rises to 160°C, the moisture contained in the machine rod is evaporated mainly by external heating and the heat generated by its own combustion. The chemical composition of the machine-made stick remains almost unchanged.

2. Initial stage of carbonization.

This stage mainly relies on the combustion of the rod itself to generate heat, causing the furnace temperature to rise to between 160 and 280°C. At this time, the wood material undergoes a thermal decomposition reaction and its composition begins to change. Among them, unstable components, such as hemicellulose, decompose to produce CO2, CO and a small amount of acetic acid and other substances.

3. Comprehensive carbonization stage

The temperature at this stage is 300~650℃. During this stage, the wood material undergoes rapid thermal decomposition, and a large amount of liquid products such as acetic acid, methanol, and wood tar are generated. In addition, flammable gases such as methane and ethylene are also produced, and these flammable gases are burned in the furnace. Thermal decomposition and gas combustion generate a large amount of heat, which increases the temperature of the furnace and the wood material is carbonized into charcoal at high temperature.

Features

1: Due to the horizontal layout, the carbonization chamber has a high space utilization rate and can meet the carbonization needs of large quantities of materials.

2: Horizontal carbonization furnaces usually use indirect heating, that is, the heat source is provided through a combustion furnace or an external heater. The materials in the carbonization chamber and the combustion gas are isolated from each other, avoiding direct contact and pollution.

3: The horizontal carbonization furnace also has the characteristics of easy operation, high carbonization efficiency, and stable quality of carbonized products.

Charcoal Machine FAQ

Q:What is the carbonization rate of your charcoal machine? How about the charcoal quality?

Q:What is the daily/monthly production capacity? Can it meet my needs?

Q:What is the daily/monthly production capacity? Can it meet my needs?

Q:Is the equipment operation stable? Prone to breakdowns?