Product description

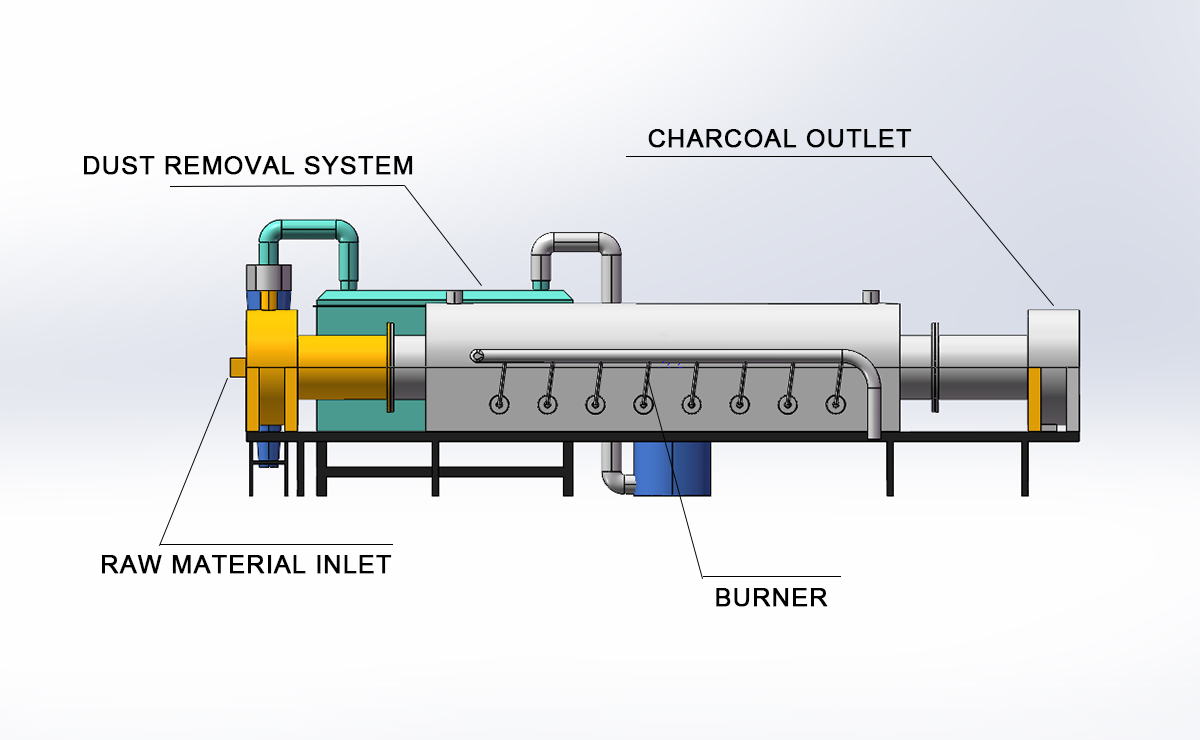

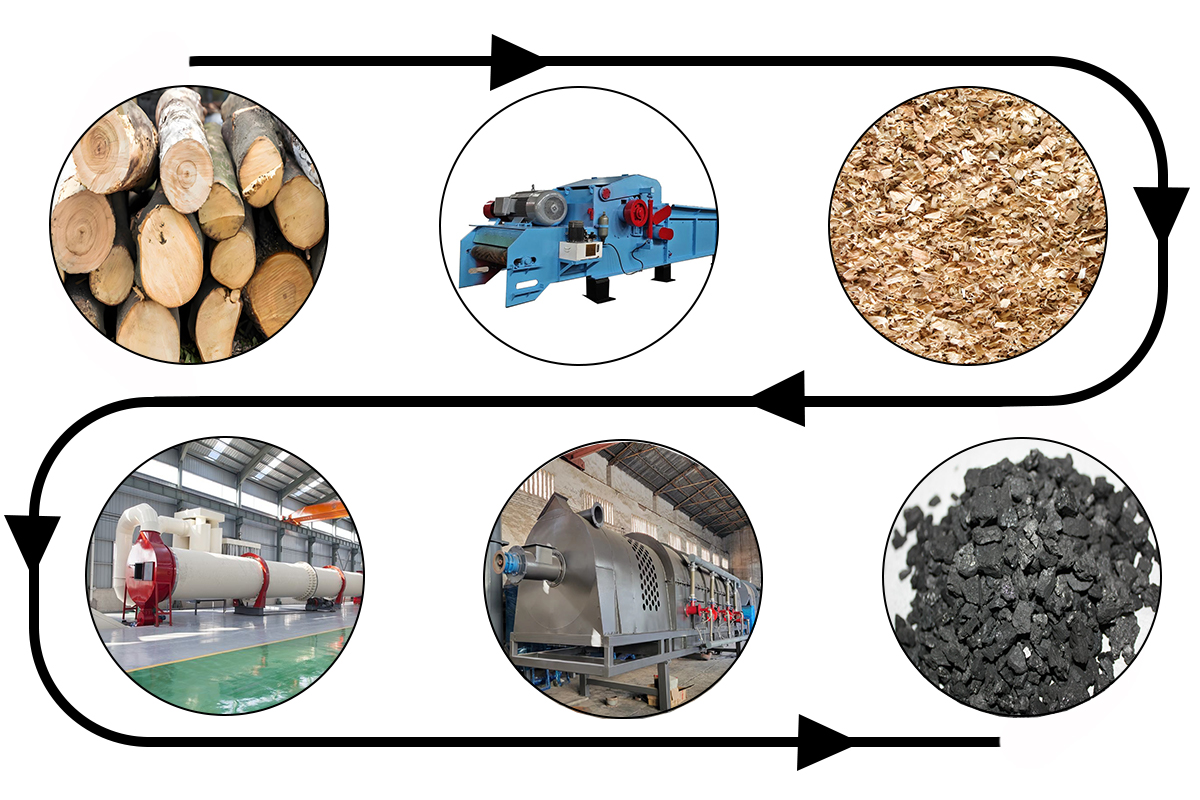

The continuous carbonization furnace is a piece of equipment that can perform carbonization operations continuously. It heats and decomposes biomass raw materials under anaerobic or low-oxygen conditions, and finally converts them into charcoal. This process mainly includes four stages: drying, thermal cracking, carbonization and cooling. Compared with traditional intermittent carbonization furnaces, continuous carbonization furnaces have higher production efficiency and lower energy consumption.

Working principle

The continuous carbonization furnace is mainly divided into three stages.

1. Drying stage: When the material enters the furnace, the furnace temperature rises, and the moisture content of the mechanical rod in the furnace is mainly evaporated by the heat generated by external heating and combustion, but the chemical structure of the material itself does not change.

2. Initial carbonization stage: At this stage, the temperature in the carbonization furnace rises to about 180~300°C. At this temperature, the material mechanism is conducive to decomposition, and the chemical structure itself also changes. Hemicellulose decomposes to produce substances such as CO2, CO and a small amount of acetic acid.

3. Comprehensive carbonization: At this stage, the temperature of the carbonization furnace increases, and the wood material inside decomposes and warms rapidly, while generating a large amount of acetic acid, methanol, wood tar and other liquid products, in addition to combustible gases such as methane and ethylene; combustible gases burn and The thermal decomposition mechanism itself generates a large amount of heat, and as the temperature rises, the wood material will become the main carbon rod.

Features

1. The continuous carbonization furnace has high production efficiency. It can produce continuous carbonization 24 hours a day, and can carbonize several tons to dozens of tons of raw materials a day.

2. Energy saving and environmental protection. It is equipped with an exhaust gas treatment device, and the final flue gas discharged meets environmental protection requirements. The exhaust gas can also be used to heat the raw material drying equipment to dry the materials. After carbonization starts, combustible gases will be generated. Our equipment will collect these combustible gases and then burn them as carbonization fuel in the furnace to provide carbonization heat energy to the entire carbonization furnace. No additional fuel is needed. The energy saving is very high. General carbonization equipment is comparable.

3. Automation. The PLC control cabinet equipped with Hengju carbonization furnace can check the operating status of the equipment. The equipment is more operable and safer.