Wood Charcoal Making Machine: A Buyer's Guide (2025)

How to Choose the Best Biomass Carbonization Machine for Your Business?

Investing in a wood charcoal making machine is a significant step towards sustainable waste management and a profitable venture. However, balancing efficiency, cost, and environmental impact requires careful consideration. With industry terms like "continuous carbonization furnace" and "biomass pyrolysis" prevalent, how do you pick the right equipment that truly meets your business needs? This guide aims to cut through the noise, providing clarity backed by 15+ years of industrial expertise in biomass processing.

The global charcoal market is projected for steady growth, estimated to expand at a Compound Annual Growth Rate (CAGR) of 6.2%. This growth presents a clear opportunity for businesses involved in biomass conversion. Our target audience includes small-to-medium charcoal producers, environmental enterprises focused on waste-to-energy, and agricultural businesses looking to monetize their residue. Understanding the technology is key to capitalizing on this trend.

1. What is a Wood Charcoal Making Machine?

At its core, a wood charcoal making machine, also known as a biomass carbonization machine or charcoal production machine, is designed to convert organic materials into high-carbon charcoal through a process called pyrolysis.

1.1 How It Works

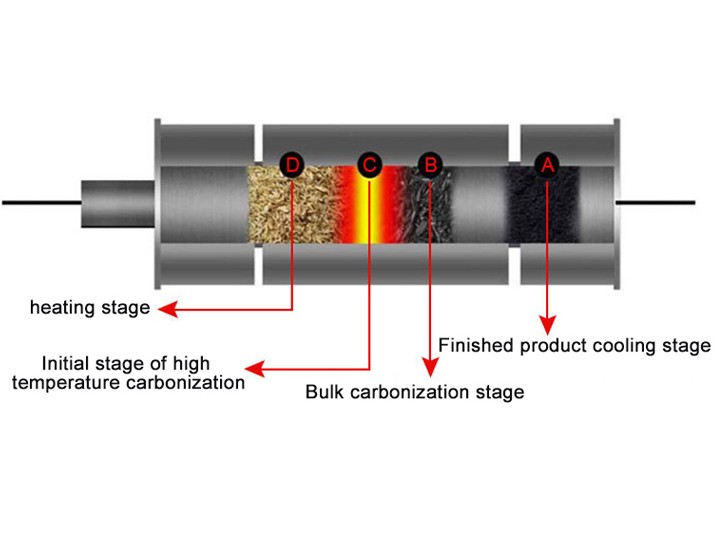

The fundamental principle involves heating biomass materials (such as wood chips, coconut shells, bamboo, rice husks, or agricultural stalks) in a high-temperature environment with minimal or no oxygen. This thermal decomposition process drives off moisture and volatile compounds, leaving behind a solid residue rich in carbon – charcoal.

While the basic principle is the same, the execution varies significantly between traditional methods and modern technology. Here’s a comparison illustrating the difference, particularly highlighting the efficiency of advanced systems like Hengju's HJ-T series continuous carbonization furnace:

| Feature | Traditional Kiln | Continuous Carbonization Furnace (e.g., Hengju HJ-T Series) |

|---|---|---|

| Production Capacity | ~200 kg/day | 500 - 2500 kg/hour |

| Labor Required | 5+ workers | 1 operator (typically PLC automation) |

| Emissions | High smoke and pollutants | Closed-loop system, near-zero visible emissions |

| Process | Batch, long cycle | Continuous, automated feed/discharge |

| Energy Efficiency | Low, external heat lost | High, utilizes self-generated syngas for heating |

1.2 Key Applications

The output from a quality charcoal production machine has diverse and valuable applications, driving demand across various sectors:

Fuel: High-quality charcoal briquettes for BBQ and domestic heating.

Industrial Use: Fuel for boilers, foundries, or activated carbon production.

Agriculture: Biochar for soil amendment, improving fertility, water retention, and carbon sequestration.

Chemical Industry: Production of carbon black, activated carbon, and other derivatives.

We've seen successful implementations globally. For example, Palm shell processors in Malaysia use our charcoal production machine to turn abundant waste into export-grade biochar, meeting international standards. Similarly, U.S. BBQ briquette manufacturers achieve 99% carbon purity with charcoal produced by systems capable of meeting stringent certifications like ISO 17225. For high-volume charcoal production machines, continuous systems reduce downtime by up to 80%, ensuring consistent supply for large markets.

2. How to Choose the Right Machine

Selecting the ideal biomass carbonization machine involves a problem-solution approach, focusing on your specific operational context and goals.

2.1 Capacity Needs

This is perhaps the most critical factor. How much raw material do you need to process daily or hourly? Do you process 100 kg/h of wood chips or 2 tons/hour of rice husks? Your required output dictates the size and type of machine. For illustration, Hengju's HJ-T4 model (approx. 100kg/h capacity) suits small farms or pilot projects, while the HJ-T18 (up to 2500kg/h) is designed for large industrial plants. Overestimating or underestimating capacity can lead to inefficiency or insufficient output.

2.2 Automation Level

The level of automation directly impacts labor costs and operational consistency. If labor expenses are a concern, prioritize PLC-controlled continuous carbonization furnaces. These systems handle feeding, carbonization temperature control, and discharge automatically. Our clients, for instance, have reported saving an estimated $20,000/year in wages after switching to an automated continuous system.

2.3 Environmental Compliance

Modern charcoal production machine technology must meet increasingly strict environmental regulations. Ensure the machine includes effective emission control systems like scrubbers, condensers, and exhaust gas combustion chambers. Look for compliance with relevant standards such as EU Standard EN 303-5 or meeting requirements like those set by the California Air Resources Board (CARB), especially if you plan to export or operate in regions with stringent air quality laws.

3. Why Choose Hengju’s Continuous Carbonization Furnace?

Building trust requires demonstrating proven capability and reliability. Hengju Machinery specializes in advanced continuous carbonization furnaces, offering features backed by real-world data and client success.

3.1 Industry-Leading Features

Our continuous carbonization furnace series incorporates innovative design elements for enhanced performance:

"2X Faster Carbonization": Achieved through a patented heat recovery and internal structure design [Link to Patent or Technical Whitepaper on your site].

"90% Less Downtime": Based on real-world operational data from a client in Indonesia [Suggest linking to or displaying a chart comparing uptime]. Our robust build quality and reliable automation contribute to consistent, uninterrupted operation.

3.2 Client Testimonials

Hearing directly from satisfied customers provides powerful social proof. Here is feedback from one of our global partners:

"After switching to Hengju's biomass carbonization machine, our ROI came in 8 months—faster than projected. The continuous operation and automated controls have transformed our production efficiency."— Carlos M., Charcoal Cooperative, Brazil

3.3 Certifications & Global Reach

Our commitment to quality and safety is reflected in our certifications, including ISO 9001 (Quality Management), CE Marking (European safety standards), and the ability to produce charcoal conforming to ISO 17225 standards (Solid biofuels - Fuel specifications and classes) [Suggest displaying certification badges here]. With 500+ installations across 30 countries, including demanding markets like Germany and Japan, and successful operations from California to Ghana, Hengju has a proven track record of delivering reliable wood charcoal making machines globally.

4. Frequently Asked Questions (FAQ)

Q1: What’s the price range for a charcoal production machine?

A: The cost varies significantly based on capacity, automation level, and included features. Small-scale models (e.g., 100kg/h capacity) might start around $18,000, while large-scale industrial systems can reach upwards of $150,000. For an accurate estimate tailored to your specific needs and raw materials, we recommend requesting a customized quote [Link to your Request a Quote page].

Q2: Can it process wet biomass?

A: Yes, our continuous carbonization furnace is designed to handle biomass with moderate moisture content. It typically includes a pre-drying stage within the system to reduce moisture to an acceptable level, usually ≤25%, before the material enters the high-temperature carbonization zone. For materials with higher moisture, a separate pre-drying step might be recommended.

Conclusion

Choosing the right wood charcoal making machine is a critical decision that impacts your project's profitability, efficiency, and environmental footprint. By understanding the technology, assessing your specific capacity and automation needs, and prioritizing environmental compliance, you can select a biomass carbonization machine that delivers reliable performance and value.

Hengju Machinery combines 15+ years of expertise with proven continuous carbonization furnace technology—helping clients worldwide scale their charcoal production machine operations reliably and sustainably.

Ready to take the next step?

Call +86 173 1979 8686 for a free consultation.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/product-guide/wood-charcoal-making-machine-a-buyers-guide-2025.html