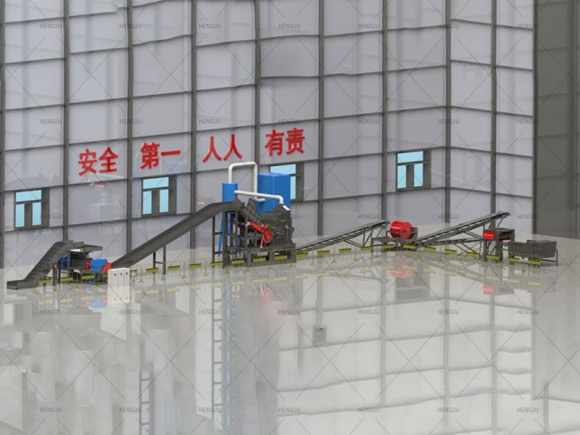

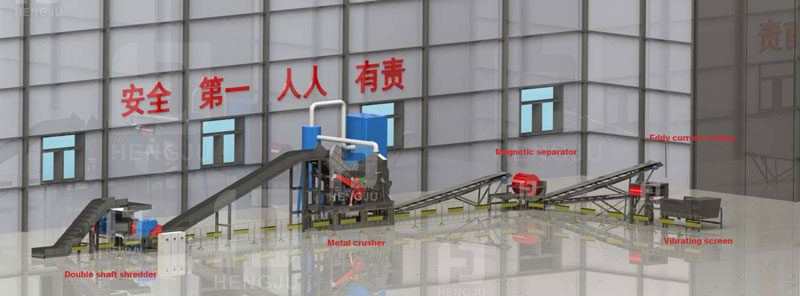

Production line process

Material manager shredder, preliminary processing. It is transported by belt conveyor to metal crusher for secondary crushing. Dust removal system removes dust from the surrounding crusher. The magnetic separator screens out the iron particles after crushing the material. The work of the vortex separator is that non-ferrous metals (such as copper, aluminum, etc.) will leap forward in the direction of transmission due to the repulsive force of the magnetic field, so as to achieve the separation of other non-metallic substances and achieve the purpose of separation

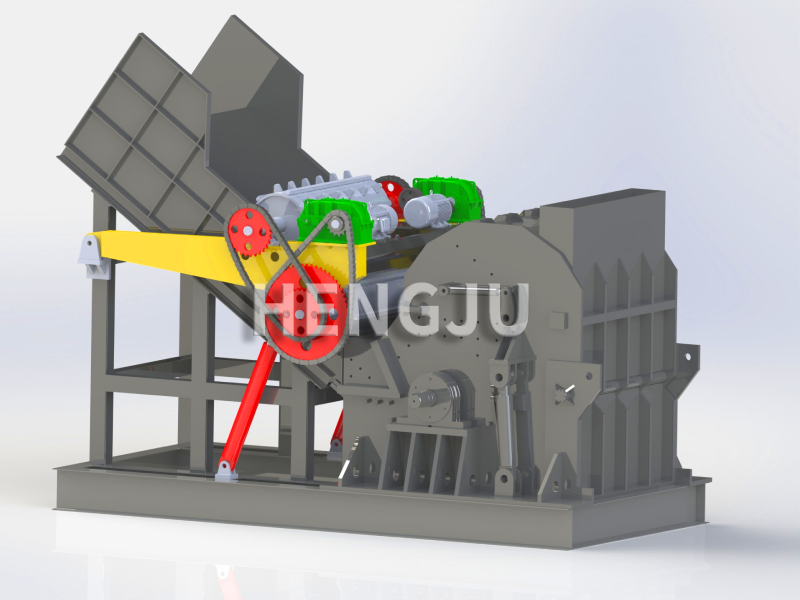

Shredder

Shredder is mainly used for shredding thin metal with a certain strength, waste domestic waste, etc., to increase its packing density in order to facilitate transportation and facilitate the next process operation.

Metal crusher

Metal crusher after scrap steel crusher treatment of high density of crushing material, high purity, steel mills and other manufacturing enterprises with crushing material re-smelting into new products, low unit energy consumption, high output, comprehensive economy is obvious. Scrap crusher is recognized as the ideal equipment for the treatment of scrap steel.

Eddy current separator

In the process of operation, high frequency alternating strong magnetic field will be generated on the surface of the separation magnetic roller. When a conductive non-ferrous metal passes through a magnetic field, eddy currents in the non-ferrous metal are induced. The eddy current itself will produce a magnetic field in the opposite direction of the original magnetic field, and non-ferrous metals (such as copper, aluminum, etc.) will leap forward along its transport direction due to the repulsive force of the magnetic field, so as to achieve the separation of other non-metallic substances and achieve the purpose of separation.