Shredder Video

Shredder equipment videos are valuable resources for individuals and businesses looking to understand and operate shredding machines effectively. These videos can range from product demonstrations and educational tutorials to maintenance guides and customer testimonials. Here's how you can access and utilize these videos:

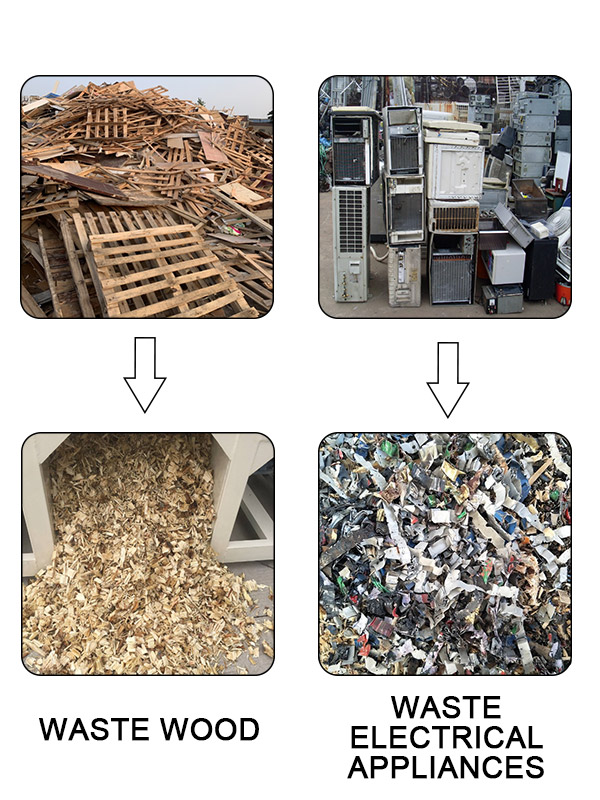

Double-shaft shredder, also known as shearing shredder, is a shredder that reduces the size of materials through shearing, tearing and squeezing.

working principle

The shaft shredder uses two sets of rotors equipped with shredder blades to rotate relatively in the machine cavity of the equipment, thereby using the principle of shrinking the angle between the two shafts to squeeze the materials entering the machine cavity. Due to the special design of the blades, the materials enter the two-axis clamp. The material behind the corners is fixed by the edges of the blades, which further creates conditions for the contraction of the angle. After the material is stressed and reaches the material yield strength, the material begins to break between the blades, thus completing the shredding effect.

Features

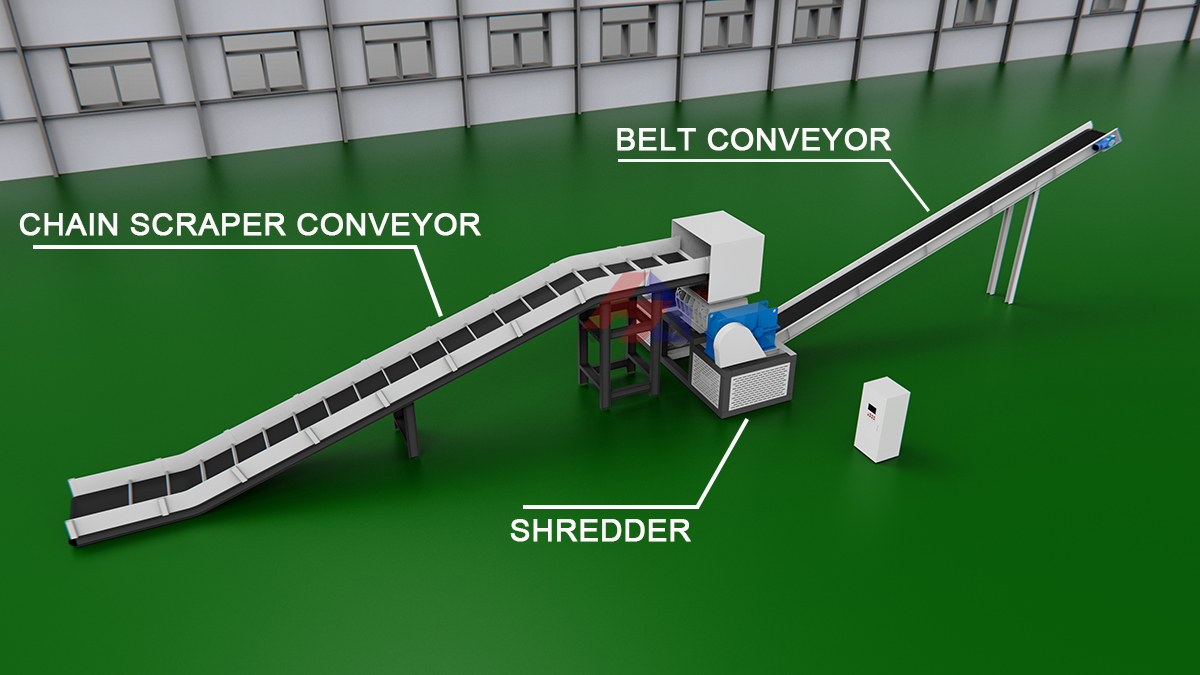

1. The form is suitable for tearing, cutting and breaking all kinds of aniseed materials, hollow materials, leftover materials, pipes, templates, tires and scrap metal products into small pieces instantly.

2. Low-speed operation, no noise, little wear, low energy consumption,high crushing pressure after compression.

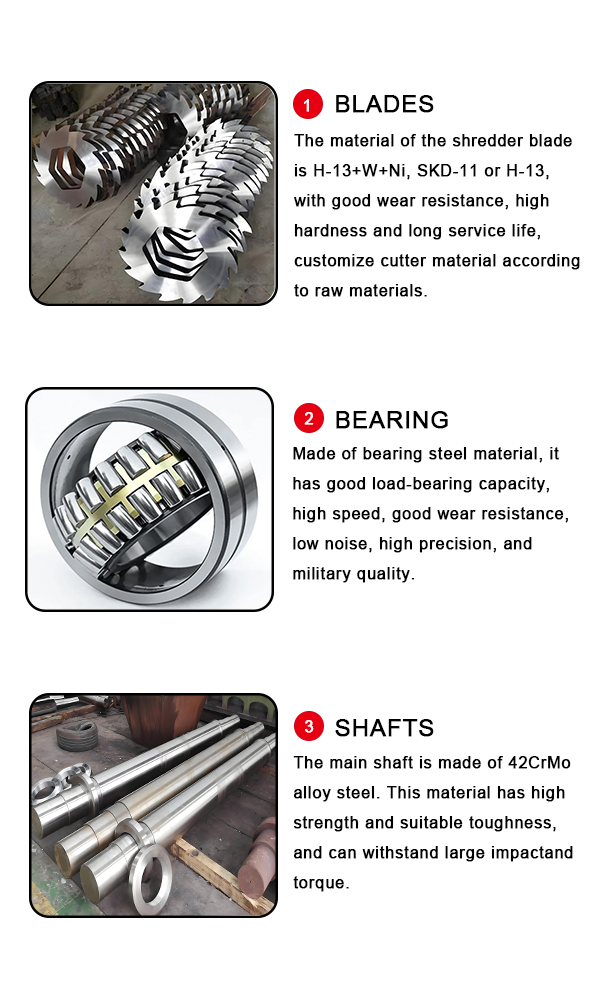

3. The box body is made of wear-resistant hard castings and is fully CNC processed to ensure use.

4. The bearings are assembled by hot pressing, which simplifies tool replacement and disassembly. The sealing rubber pad prevents dust from entering.

5. All the cutter head spindle cutter head holes are connected with hexagonal holes to prevent rolling and prepare for super torque.

6. All connecting bolts are made of high-strength bolts and lock nuts, which will not loosen and ensure use.

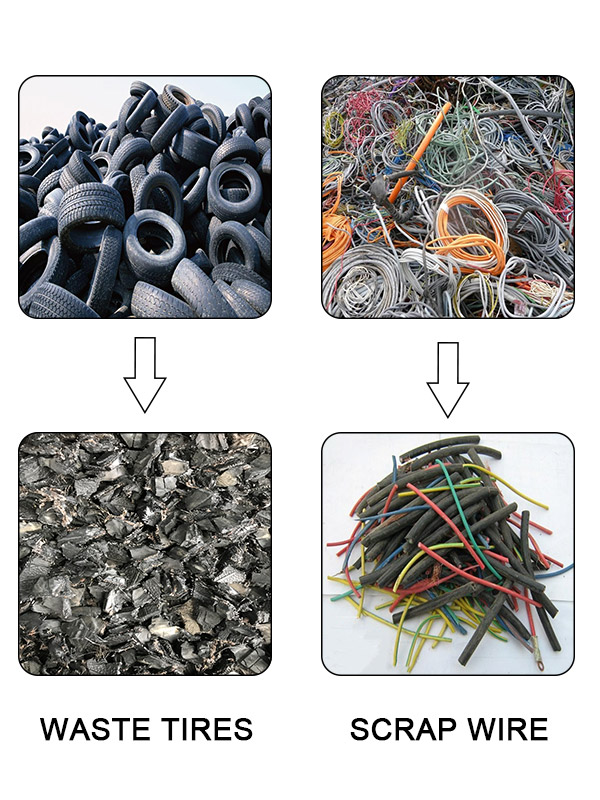

Scope of application

The main function of the double-shaft shredder is to cut large pieces of materials that are inconvenient to transport into materials that meet the requirements through shearing. Suitable for industrial waste recycling, pallet production, wood processing, medical recycling, electronic production, domestic waste recycling, plastic recycling, tire recycling, paper making and other industries. Various hollow containers, used household appliances, used plastic and rubber products, scrap iron, municipal waste, domestic waste, electronic waste, scrapped vehicles and other debris.