Activated carbon is a functional carbon material. Due to its large specific surface area, developed pore structure, high adsorption efficiency and good chemical properties, it is widely used in industry, agriculture, medical treatment, food and other aspects, such as gas purification, sewage treatment, pharmaceutical industry , sugar production, etc.

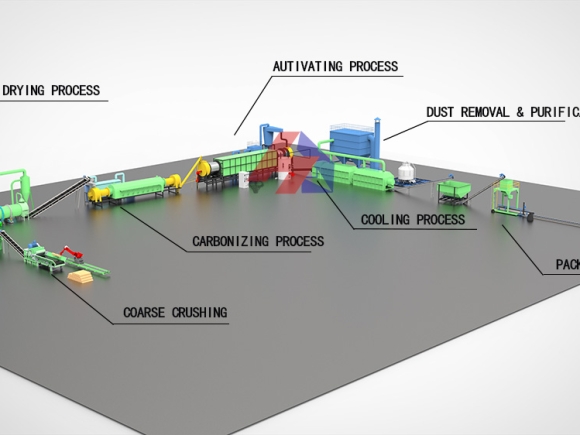

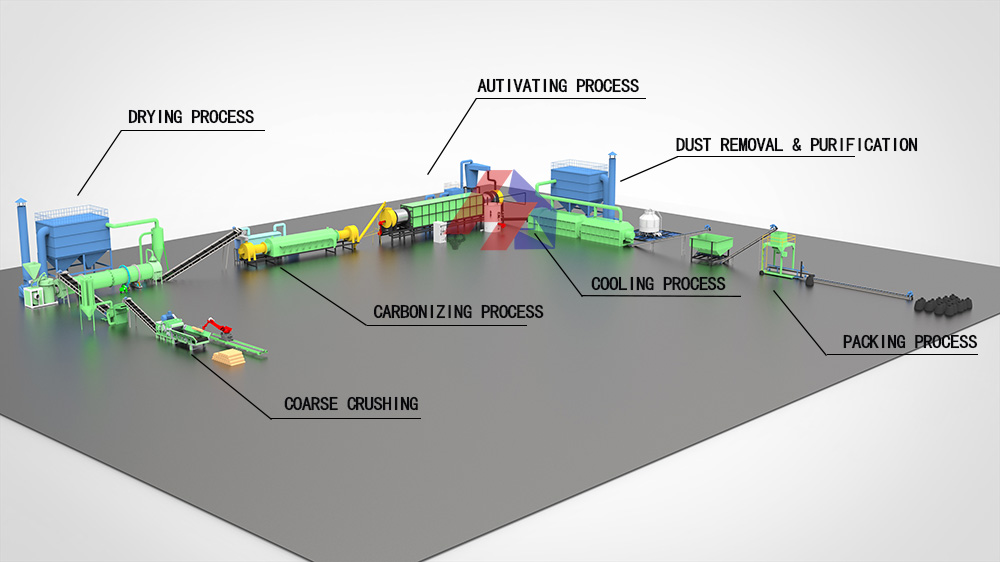

The activated carbon production process is as follows:

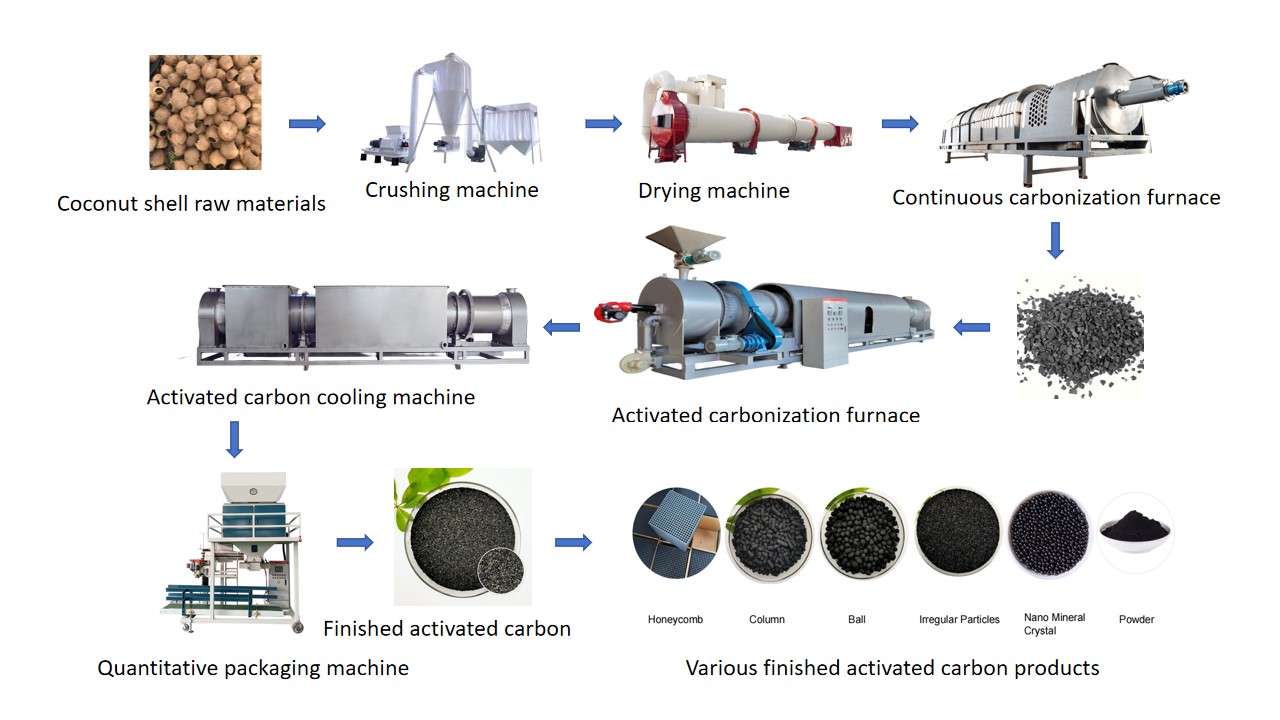

Raw materials ------ (The raw materials for making activated carbon are mainly coconut shells, walnut shells, fruit wood shells, bamboo, hardwood and coal, etc.)

1. Conveyor

The raw materials are transported to the crusher through the belt conveyor for crushing.

2. Crusher

The crusher crushes the raw materials into suitable sizes, and is equipped with dust removal equipment to reduce dust during the crushing process; after that, the raw materials are transported to the dryer for drying processing through the conveyor;

3. Drying (dust removal)

The rotary drum dryer dries the crushed raw materials until the moisture content reaches a suitable range. The dust generated during the drying process is reduced by matching dust removal equipment. The dried raw materials are transported by the conveyor to the continuous carbonization furnace for the carbonization process;

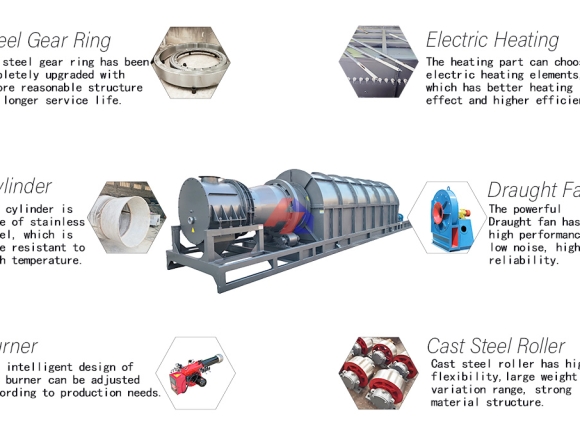

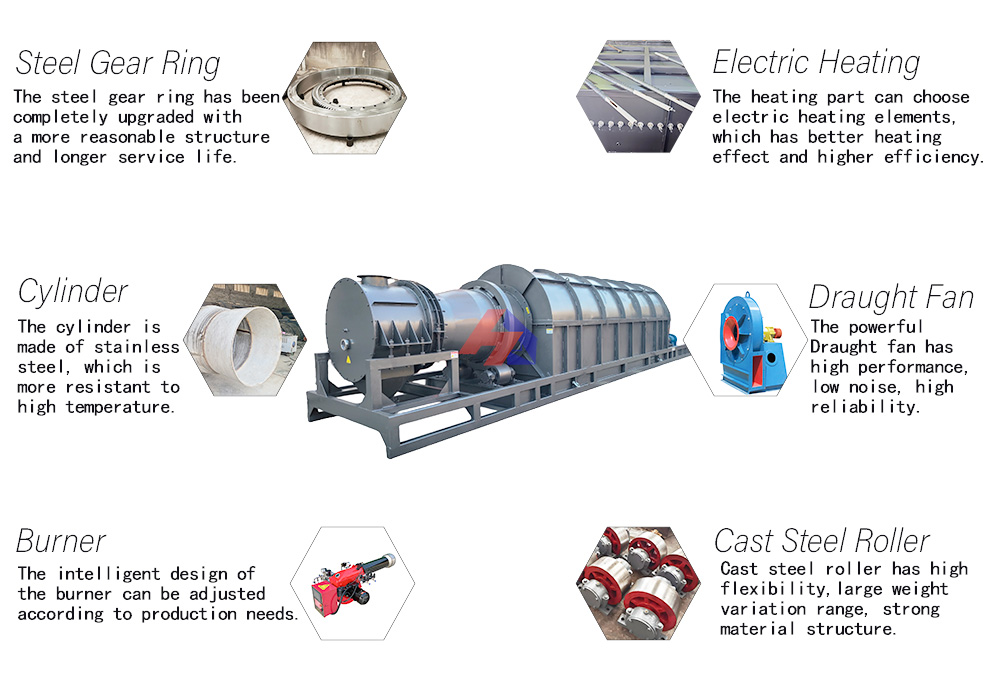

4. Continuous carbonization furnace (dust removal)

The dried raw materials enter the continuous carbonization furnace, where they undergo the carbonization process and are finally made into charcoal. The charcoal making process will produce dust, carbon monoxide, carbon dioxide, coal tar, wood vinegar and other mixtures. These substances will be professionally processed by the equipped condensation dust removal equipment and recycling equipment, and the generated coal tar mixture will be recycled into storage containers. The produced charcoal is transported by a conveyor to the activation furnace for the activation process.

5. Activated carbon furnace (dust removal)

After pyrolysis of charcoal at high temperature in the activation furnace, it is made into activated carbon. Carbon ash, carbon monoxide, carbon dioxide and other substances generated in the process of making activated carbon will be professionally dust-reduced in the equipped condensation dust removal equipment. The produced activated carbon is transported by the conveyor to the cooler for cooling.

6. Cooling equipment

After pyrolysis, the temperature of the finished activated carbon is very high and needs to be cooled down in cooling equipment. The cooled activated carbon is transported to the packaging machine for packaging.

7. Packaging equipment

According to different packaging weight requirements, select appropriate packaging bags for finished activated carbon, and use quantitative packaging machines to quantitatively package the finished activated carbon into 10KG-50KG or other weight standards to facilitate transportation and sales.

8. Storage of finished activated carbon

The finished activated carbon needs to be stored in a ventilated, dry environment with complete fire protection facilities.