1

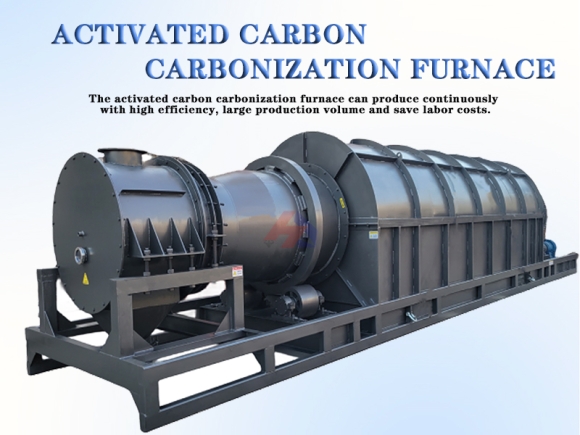

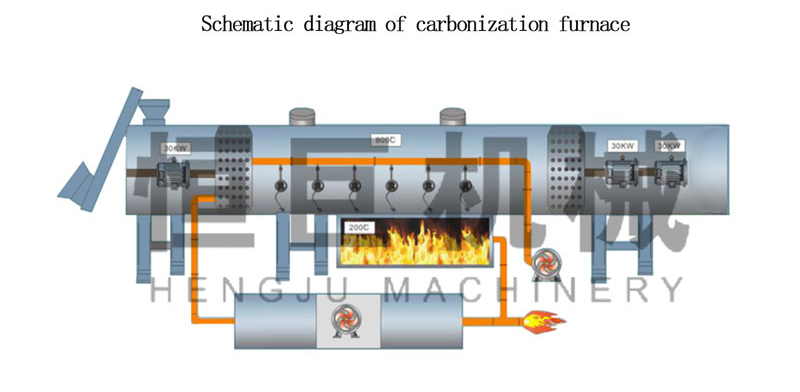

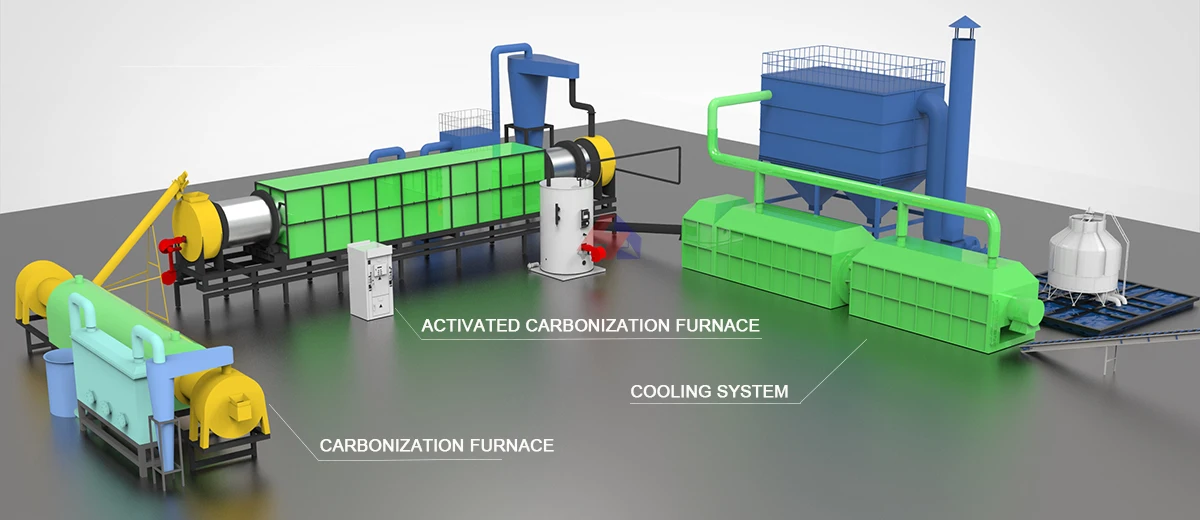

Activated Carbon Carbonization Furnace Workflow diagram

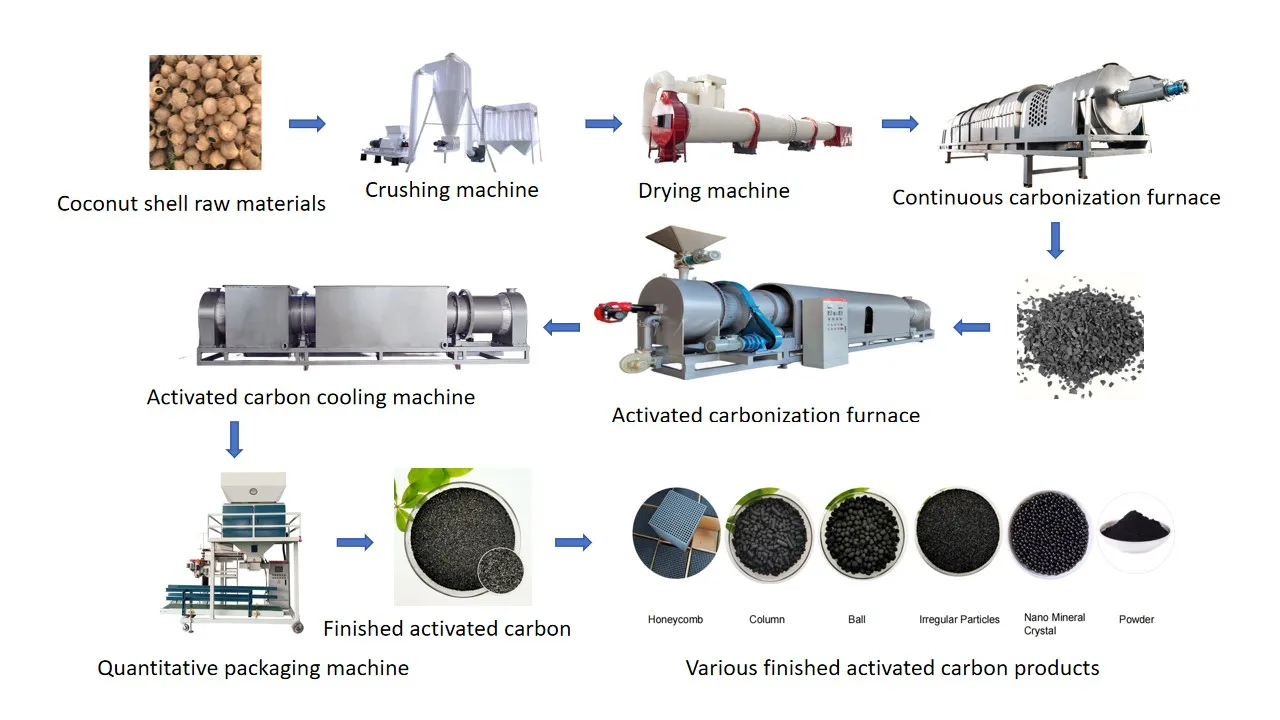

The process of converting raw materials into activated carbon does not involve any chemical reaction. The main process is: raw materials---crushing-------drying-------carbonization---------activated carbon furnace-------cooling-----------screening---------quantitative packaging--------finished activated carbon

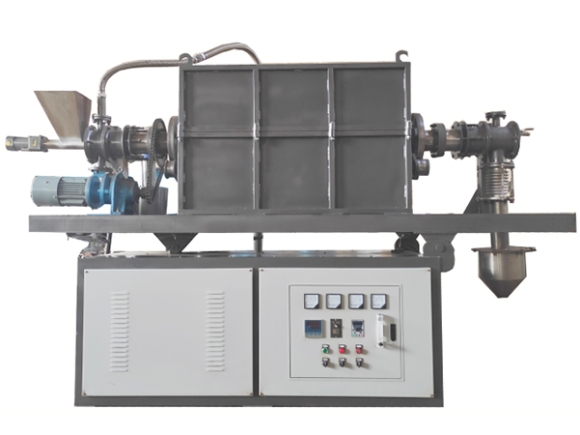

Work principles

It mainly uses its own carbon element, uses air (hydrogen) as the combustion accelerator, rotates and burns in the activation furnace, reaching a temperature above 1000°C, and then uses water vapor, carbon dioxide, and hydrogen as the activator and activation medium. For activated carbon, the production process is relatively simple, and there is no pollution problem in the physical activation furnace during the production process.

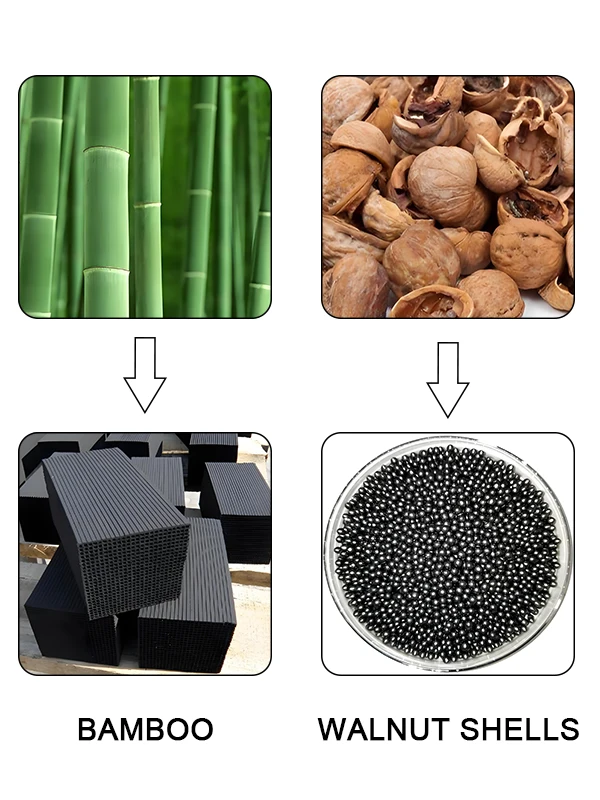

Raw material range:

Coconut shell, walnut shell, apricot shell, peach shell, bamboo, coal and other high-quality hardwoods. These raw materials have developed pore structures, strong hardness, and low ash content after high temperature. They are the best raw materials for making activated carbon.

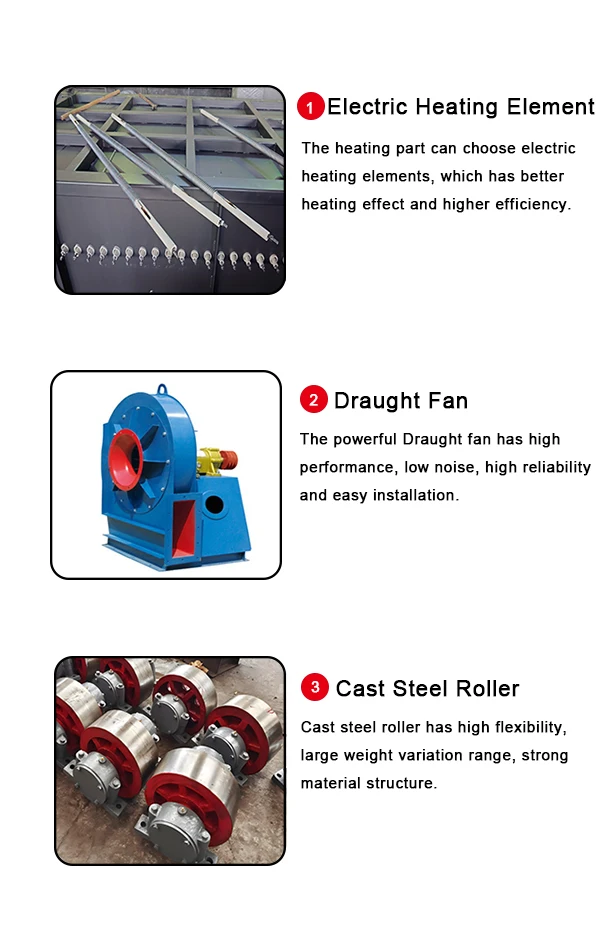

Advantages of activated carbon furnace:

1. It can work continuously. The drum is designed with an inclination angle and can rotate continuously. The produced activated carbon will slowly move to the discharge port.

2. The speed of the furnace body can be freely controlled, and the adjustability of the entire high-temperature activation process is large.

3. The activation temperature can be adjusted, and the burner can automatically make up the temperature according to the temperature in the furnace.

4. The furnace tube is made of stainless steel, which is resistant to high temperature and heats up quickly.

5. Simple operation, and there are almost no vulnerable parts in the whole machine. The activated carbonization furnace is equipped with an intelligent control system with a high degree of automation.