"Before switching to the Continuous Carbonization Furnace, our charcoal production was painfully slow and inconsistent. We were constantly battling bottlenecks and struggling to meet demand. This furnace has been a game-changer! The continuous operation is incredible – we've more than doubled our output with the same workforce. No more wasted time waiting for batch cycles. If you're serious about scaling your charcoal business, this is the investment you need. It paid for itself faster than we ever imagined!"

Continuous Carbonization Furnace | 24/7 Automated Production, 30% Energy Saving

Convert Biomass Waste into High-Quality Charcoal with Zero Emissions – From 100kg/h to 2500kg/h Capacity

Reliable & Efficient

Charcoal Production Solutions

Trusted by 500+ Manufacturers Worldwide

Are you looking for a reliable and efficient way to produce high-quality charcoal? Our advanced wood charcoal machine is engineered to exceed your production targets .

🏭 Industry Expertise

15+ years refining manufacturing technology for optimal performance

📈 Scalable Solutions

Modular systems from 500kg to 5ton/hour production capacity

| ⚡ Production Revolution | ||

|---|---|---|

|

⏱️

|

2X Faster Production

↑ 150% Output

|

Automated continuous operation enables 24/7 production cycles with 90% less manual intervention. Intelligent sensors maintain optimal pyrolysis conditions (±5°C) for maximum throughput. |

|

💰

|

Smart Cost Control

↓ 40% OPEX

|

Closed-loop energy recovery system reduces fuel consumption by 65%. Predictive maintenance algorithms cut downtime costs by 80% compared to conventional systems. |

|

🌟

|

Premium Quality

ISO 17225 Certified

|

Precision temperature control ensures 99% carbon purity. Automated sorting system guarantees uniform charcoal size (Ø25±2mm) meeting export-grade specifications. |

Performance Comparison

Traditional Methods vs Our Modern Machines

| Metric | Traditional Methods | Our Machines | Improvement |

|---|---|---|---|

| Production Capacity | 200 kg/hour | 500 kg/hour | ↑ 150% |

| Energy Consumption | 100% | 70% | ↓ 30% |

| Labor Costs | 100% | 50% | ↓ 50% |

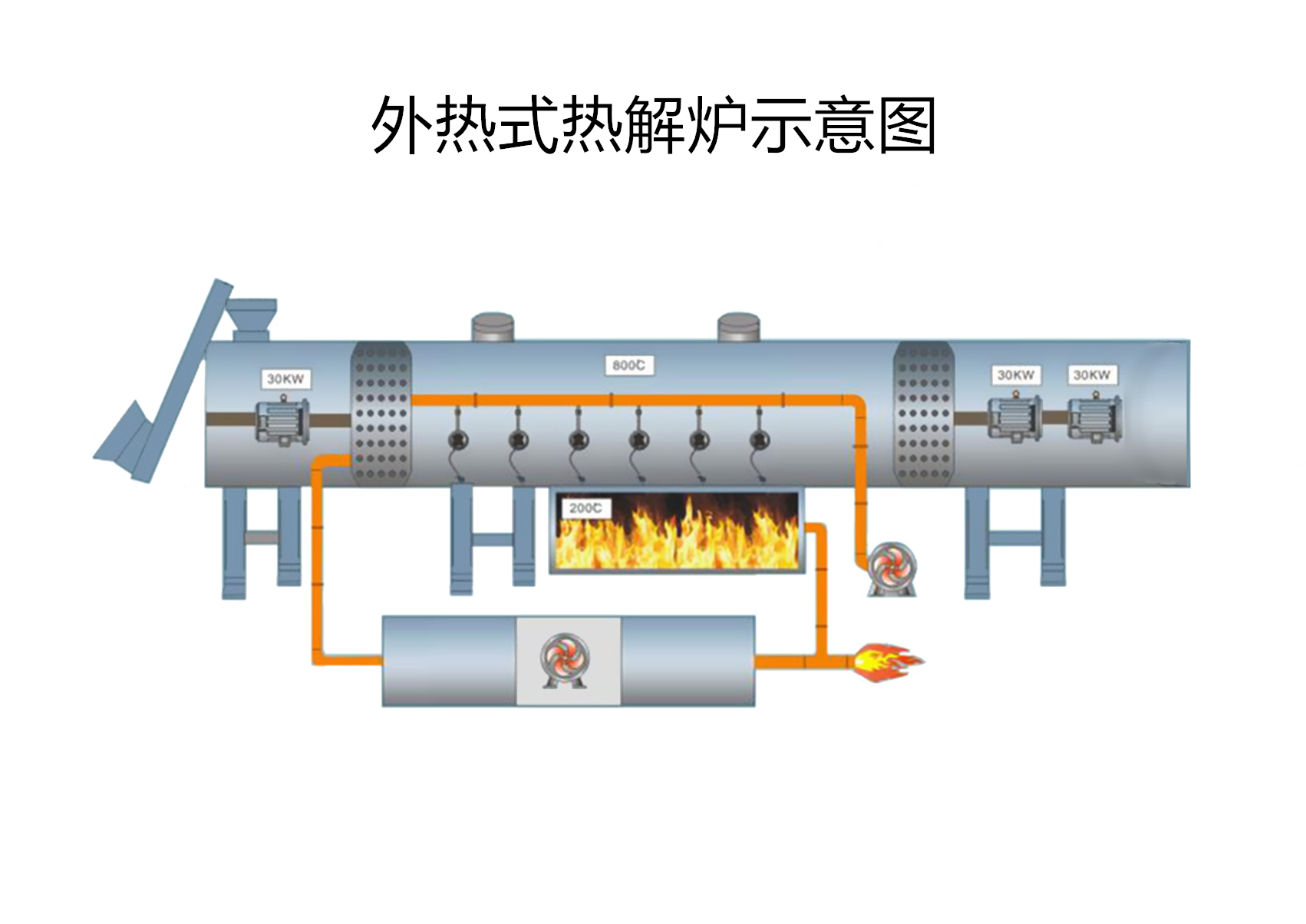

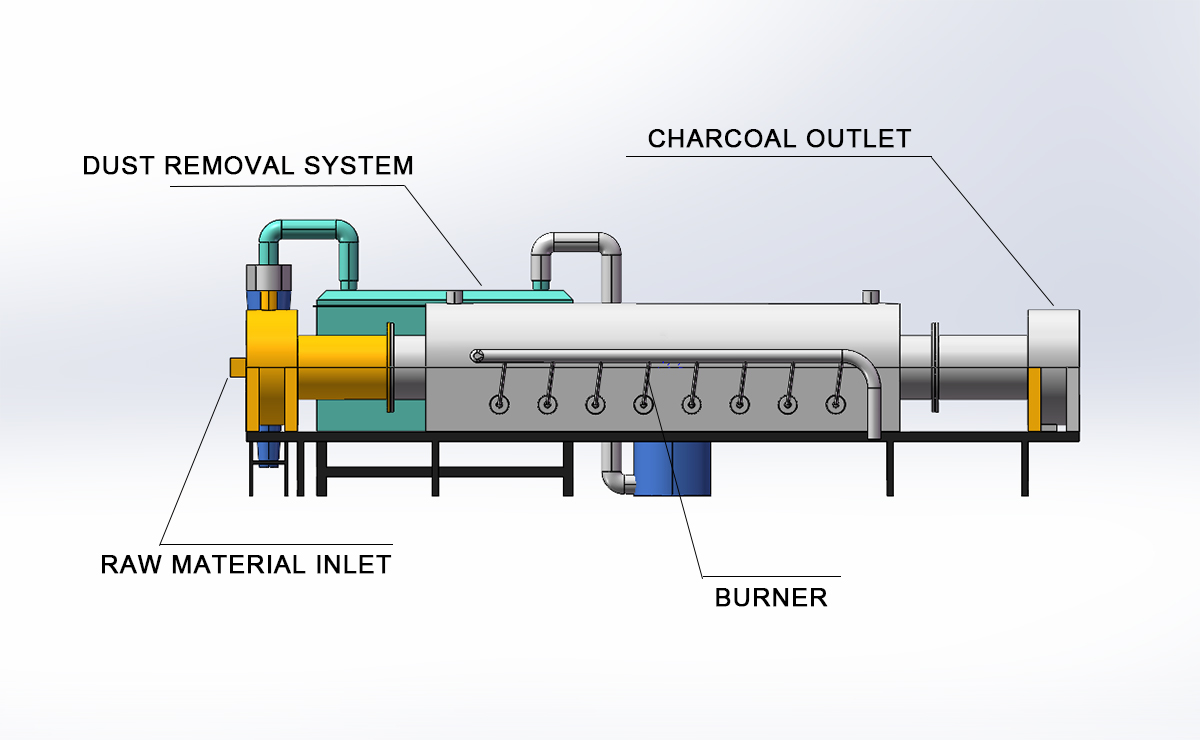

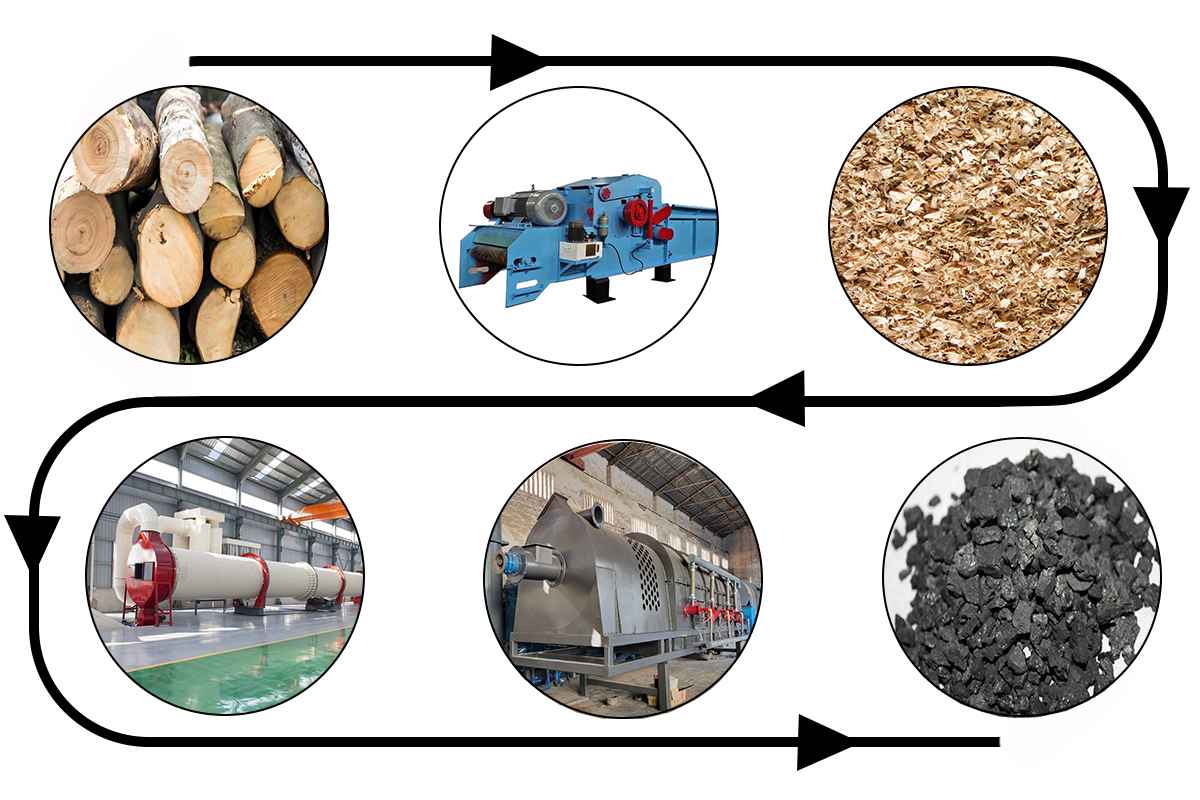

The continuous carbonization furnace is a piece of equipment that can perform carbonization operations continuously. It heats and decomposes biomass raw materials under anaerobic or low-oxygen conditions, and finally converts them into charcoal. This process mainly includes four stages: drying, thermal cracking, carbonization and cooling. Compared with traditional intermittent carbonization furnaces, continuous carbonization furnaces have higher production efficiency and lower energy consumption.

Working principle

Continuous carbonization furnaces are industrial systems designed to efficiently convert biomass materials like wood, agricultural waste, and coconut shells into high-quality charcoal through uninterrupted thermal processing. These systems operate through a high-temperature pyrolysis method under oxygen-deprived conditions, enabling non-stop production that outperforms traditional batch-type kilns in both output capacity and operational efficiency.

The resulting charcoal serves multiple practical applications. As a premium fuel source, it's commonly used for residential heating and outdoor grilling. Industrial operations value its high thermal efficiency and cost-effectiveness for applications ranging from metallurgical processes to powering industrial boilers and ceramic kilns. In agricultural applications, processed charcoal can be converted into biochar - a valuable soil amendment that improves nutrient retention and crop productivity. Additional uses span construction materials manufacturing, production of activated carbon for filtration systems, and specialized industrial applications including gunpowder production and lubricant formulations.

The continuous carbonization furnace is mainly divided into three stages.

1. Drying stage: When the material enters the furnace, the furnace temperature rises, and the moisture content of the mechanical rod in the furnace is mainly evaporated by the heat generated by external heating and combustion, but the chemical structure of the material itself does not change.

2. Initial carbonization stage: At this stage, the temperature in the carbonization furnace rises to about 180~300°C. At this temperature, the material mechanism is conducive to decomposition, and the chemical structure itself also changes. Hemicellulose decomposes to produce substances such as CO2, CO and a small amount of acetic acid.

3. Comprehensive carbonization: At this stage, the temperature of the carbonization furnace increases, and the wood material inside decomposes and warms rapidly, while generating a large amount of acetic acid, methanol, wood tar and other liquid products, in addition to combustible gases such as methane and ethylene; combustible gases burn and The thermal decomposition mechanism itself generates a large amount of heat, and as the temperature rises, the wood material will become the main carbon rod.

Features

1. The continuous carbonization furnace has high production efficiency. It can produce continuous carbonization 24 hours a day, and can carbonize several tons to dozens of tons of raw materials a day.

2. Energy saving and environmental protection. It is equipped with an exhaust gas treatment device, and the final flue gas discharged meets environmental protection requirements. The exhaust gas can also be used to heat the raw material drying equipment to dry the materials. After carbonization starts, combustible gases will be generated. Our equipment will collect these combustible gases and then burn them as carbonization fuel in the furnace to provide carbonization heat energy to the entire carbonization furnace. No additional fuel is needed. The energy saving is very high. General carbonization equipment is comparable.

3. Automation. The PLC control cabinet equipped with Hengju carbonization furnace can check the operating status of the equipment. The equipment is more operable and safer.

Charcoal Making Machine Operation Demo Video

Charcoal Machine FAQ

- • Electricity/Fuel

- • Labor

- • Maintenance

• Call +86 173 1979 8686 for direct consultation

• [Online Inquiry] for quick response

Customer Testimonials

"Environmental regulations were becoming a major headache for our wood processing facility. Our old carbonization method was smoky and inefficient, and frankly, unsustainable. The Continuous Carbonization Furnace solved all of that. The clean emissions are a huge relief, allowing us to operate worry-free and even improve our community image. Beyond compliance, the energy savings from the gas recovery system are significant. It's a win-win: good for the environment and good for our bottom line."

"Consistency is key in the charcoal market, especially for high-end applications like activated carbon. With our previous furnace, quality was always a gamble. This Continuous Carbonization Furnace gives us unprecedented control over the carbonization process. The charcoal is uniformly excellent, batch after batch. This consistent high quality has allowed us to expand into new markets and command premium prices. It's not just a furnace, it's a quality assurance machine!"

"We were hesitant to upgrade to a continuous system, fearing complex operation and high labor costs. We were pleasantly surprised! This furnace is remarkably easy to operate – our team picked it up quickly. The automation is fantastic, significantly reducing manual labor. We've been able to redeploy staff to other areas of our business, increasing overall efficiency. Don't be intimidated by 'continuous' – this furnace is surprisingly user-friendly and labor-saving."

READY FOR TRANSFORMATION? Automate Your Charcoal Production

Ready to boost your charcoal production? Contact us today to get a quote for our charcoal machines. Our team of experts will be happy to help you choose the right machine for your needs.