The biomass pellet production line is an environmentally friendly project that uses various biomass wastes such as straw, branches, and rice husks as raw materials to process them into solid fuel pellets.

Raw materials: There are many raw materials for pellet production, such as crop straw, fruit shells, tree bark, sawdust, sawdust, bamboo chips, straw, vines, peanut shells, etc.

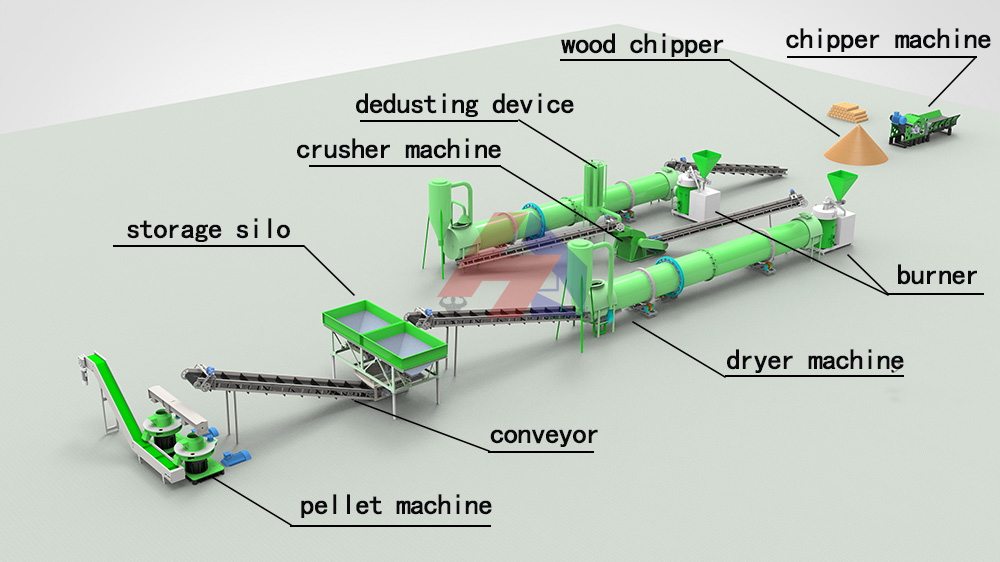

The production process of the wood pellet processing plant is: wooden raw materials ------- crushing --- drying --- granulating ------- cooling ------- Packaging------Storage of finished biomass pellets.

1. Raw materials (wooden structural raw materials)

2. Conveyor:

Transport the wood raw materials to the crusher via conveyor

3. Wood crusher (dust removal)

The raw materials are crushed into uniform-sized wood particles, and dust removal equipment is equipped to reduce dust during the crushing process; after the raw materials are crushed, they are transported to the dryer through a conveyor for the drying process.

4. Dryer (dust removal)

The rotary drum dryer dries the crushed raw materials until the moisture content reaches an appropriate range. The dust generated during the drying process is reduced by matching dust removal equipment. The dried raw materials are transported by a conveyor to the continuous carbonization furnace for the carbonization process; (the biomass pellet machine has strict requirements on the moisture content of the raw materials. If the moisture content of the raw materials is too high, the biomass pellets will break or Low density and difficult to form).

5. Biomass pellet machine (dust removal)

The wood chips entering the biomass pellet machine are squeezed by the pressure roller and ring die of the biomass pellet machine to make the wood chips into high-density biomass pellets with a diameter of 6-12MM. Equipped with professional vacuum dust collection equipment, the wood chips can be processed during the granulation process. The generated wood dust is recycled.

6.Counter flow cooler

The freshly produced biomass pellets have a high temperature and cannot be bagged directly. They need to be cooled in a countercurrent cooler.

7. Packaging machine

For finished biomass particles, according to different packaging weight requirements, select appropriate packaging bags and use quantitative packaging machines to quantitatively package the biomass particles into 10KG-50KG or other weight standards to facilitate storage, transportation and sales.

8. Storage of finished biomass pellets

The finished biomass pellets need to be stored in a ventilated, dry environment with complete fire protection facilities.