Biomass pellet machine is a kind of biomass energy pretreatment equipment. It mainly uses agricultural and forestry processing waste such as wood chips, straw, rice husks, bark and other biomass as raw materials, and solidifies them into high-density pellet fuel through pretreatment and processing. Biomass pellet machines are divided into flat-die biomass pellet machines and ring-die biomass pellet machines.

working principle

The working principle of the ring die pellet machine mainly relies on the pressure and friction between the template and the mold to gradually shape the raw materials and finally cut them into granular products. The specific process is as follows:

1. Feeding: The biomass raw materials are fed through the feeder, and then sent into the hopper of the ring die pellet machine after pretreatment such as crushing and mixing.

2. Extrusion: The raw materials are subjected to the force between the high-speed rotating template and the stationary mold in the hopper, and gradually form granular materials.

3. Cutting: After extrusion, the granular material is pushed to the inside of the mold to form a ring shape. The cutting edge on the inside of the mold cuts the particles to produce granular products with the same length.

4. Discharging: The granular products are sent to the discharging port to produce the products of the ring die pellet machine.

Biomass pellet machine Flow chart

Scope of application

Stem fuel (i.e. biofuel) uses solid waste from crops such as corn stalks, wheat straw, rice straw, peanut shells, corn cobs, cotton stalks, soybean stalks, weeds, branches, leaves, sawdust, bark and other solid waste as raw materials.

Biomass pellet machine Use Scenarios

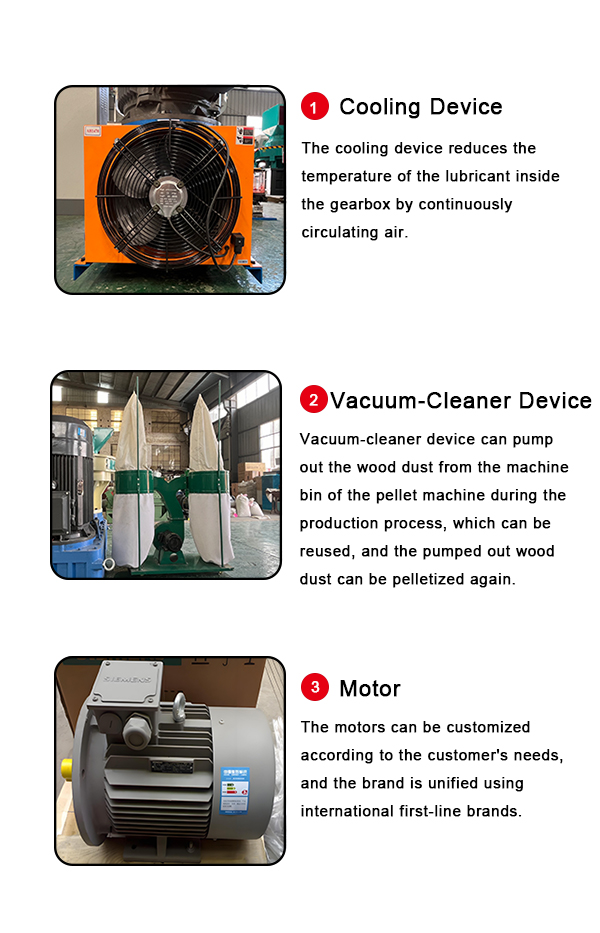

Advantages of biomass pellet mill:

1. The motor and the main shaft of the pellet machine are installed parallel and vertical, which can reduce the energy loss in the transmission process, and the output power is bigger and the energy efficiency conversion is higher.

2. Integral gearbox, reducer shell overall casting, not easy to deform, good rigidity, high stability

3. High degree of automation of the control system, the control system of the wood chip pellet mill, you can use the tablet PC and mobile APP, real-time monitoring of the temperature of the key components and the current of the equipment.

4. Self-injecting oil circulating oil pump, automatically provide continuous and stable lubrication for the pellet machine parts to avoid wear and tear.

6. High wear-resistant and high-capacity stainless steel wood chip pellet mill mold or 42CrMo material grinding tool.