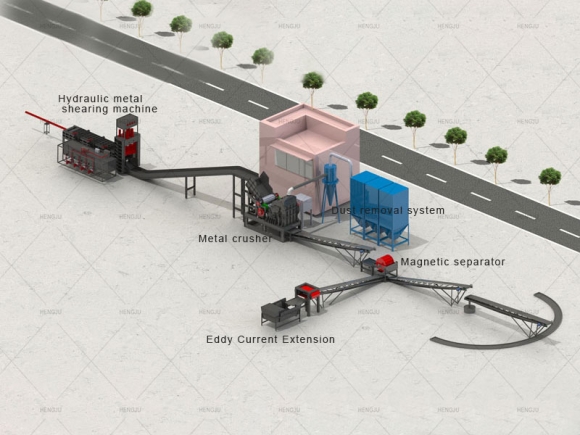

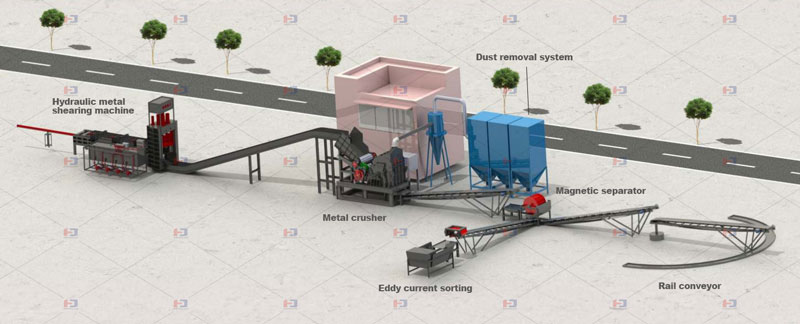

Production line process

Heavy scrap and entangled materials that cannot be processed by scrap steel crushing equipment are initially sheared by hydraulic metal shears. It is transported to the metal crusher through a conveyor belt for crushing again into smaller particles. At the same time, the dust removal system removes the surrounding dust and purifies the air. Finally, the crushed materials are magnetically separated by a magnetic separator and can be sorted into piles through an orbital conveyor belt.

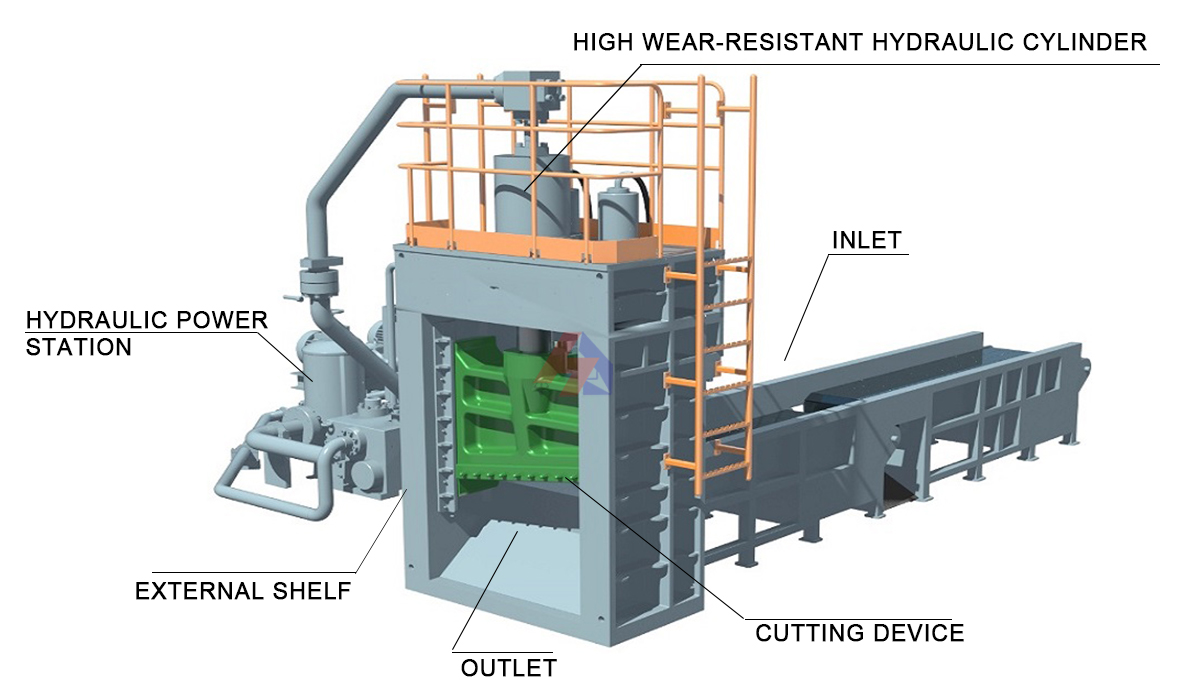

Hydraulic metal shearing machine

The hydraulic metal shearing machine is suitable for cutting I-beams, scrap rails, light steel materials, steel bars, nickel plates, round steel, steel pipes, scrap copper, scrap steel, scrap iron, light metal structural parts, stainless steel, metal briquettes, and automobile bodies. , aluminum alloys, copper materials, iron filings, steel wires, metal briquettes, etc., heavy scrap and winding metal materials that cannot be processed by scrap steel crushing equipment. This equipment can cut and crush materials at one time to replace manual dismantling and reduce costs.

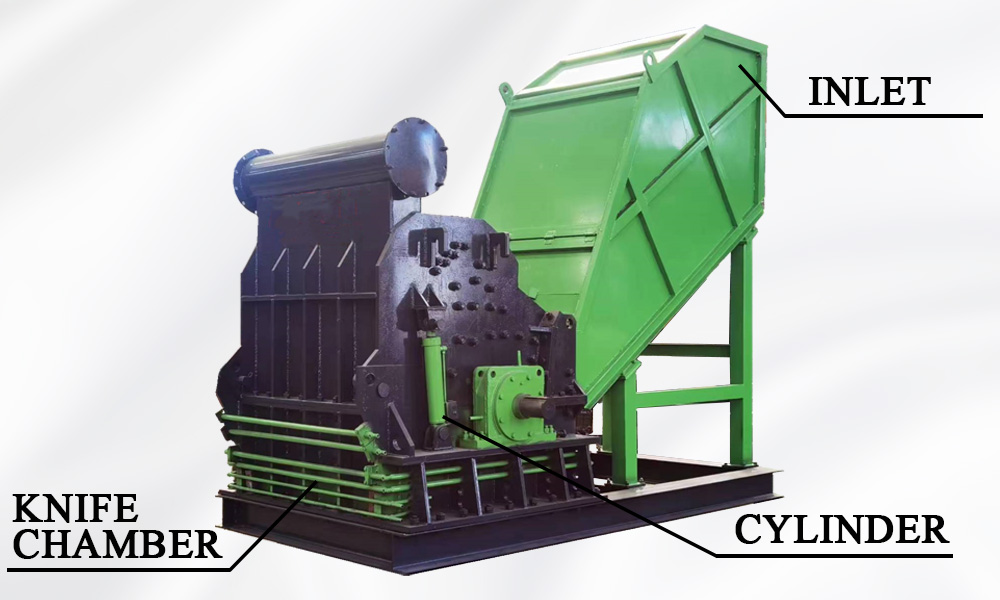

Crusher

The main casing of the crushing line is made of extra-thick steel plate, and the lining is high manganese steel casting, which is replaceable; the rotor disk of the main machine is installed on the horizontal axis, with pins distributed around the circumference of the rotor disk, and a hammer head suspended in the axial direction; the main shaft is equipped with balls Bearing support, forced lubrication and cooling by circulating oil, and equipped with a temperature sensor; the feed port is equipped with a hydraulic roller feeding device, one high and one low, rotating in the same direction, which can flatten large loose materials and send them into the crushing cavity Inside.

Magnetic separator

Magnetic separator is a kind of screening equipment, suitable for the separation of substances with magnetic differences, and can remove iron particles from broken aluminum.