What is the difference between a wood pellet making machine and a wood pellet pressing machine?

In the field of biomass energy and material processing, wood pellet making machines and wood pellet presses are two common but different types of equipment. This article will compare the features of these two machines in detail to help you better understand their application scenarios and selection criteria.

Uses and functions

Wood pellet making machine:

Main use: Process wood materials into pellet fuel

Raw material range: Wood, bamboo chips, crop straw and other biomass

Application areas: Biomass power generation, boiler fuel, household fireplace, etc.

Features: No need to add adhesives, using the biomass' own lignin as a natural adhesive

Wood pellet press machine:

Main use: Press wood chips into flake products

Raw material range: Mainly wood chips, adhesives can be added

Application areas: Fuel production, building materials production, gardening supplies, etc.

Features: Adhesives can be added according to needs, and the product shape is flake

Production process and equipment structure

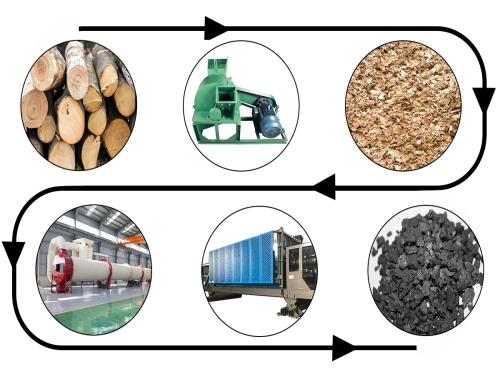

Wood pellet making machine production line:

Equipment composition: Wood crusher, dryer, wood pellet making machine, cooler, screening machine, packaging machine

Process flow: Crushing → Drying → Granulation → Cooling → Screening → Packaging

Core technology: High-pressure extrusion molding, using friction heat to activate lignin

Wood pellet press machine production line:

Equipment composition: Wood crusher, dryer, mixer, wood pellet press machine, packaging machine

Process flow: Crushing → Drying → Mixing (adding adhesive) → tableting → packaging

Core technology: high-pressure and high-speed stamping, adhesives can be added to improve the molding effect

Product characteristics and application advantages

Wood pellets:

Shape: cylindrical, usually 6-8mm in diameter

Density: high density, conducive to storage and transportation

Combustion efficiency: high, suitable for automated combustion systems

Environmental protection: no additives, less ash after combustion

Wood tableting:

Shape: flakes, size can be customized according to needs

Density: adjustable, depending on the degree of pressing and the amount of adhesive

Flexible use: can be used as fuel, building materials or horticultural products

Customization: properties can be changed by adding different adhesives

Selection suggestions

If you mainly produce biomass fuel, it is recommended to choose a wood pellet maker

If you need to produce a variety of wood products, a wood pellet flaking machine may be more suitable

Considerations: raw material source, target market, production scale, investment budget, etc.

Conclusion:

Wood pellet makers and wood pellet flaking machines each have their own unique application areas and advantages. Choosing the right equipment is crucial to improving production efficiency and product quality. Henan Hengju Machinery Equipment Co., Ltd. offers two types of advanced equipment and can provide customized solutions according to your specific needs. No matter which equipment you choose, we will provide you with comprehensive technical support and after-sales service to help you succeed in the field of biomass processing.

For more information or professional advice, please feel free to contact our team of experts.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/what-is-the-difference-between-a-wood-pellet-making-machine-and-a-wood-pellet-pressing-machine.html