What Activated Carbon Production Equipment Do I Need to Buy to Open an Activated Carbon Manufacturing Plant?

Activated Carbon Manufacturing Plant Equipment Guide: Full Process Analysis from Raw Materials to Finished Products

Opening an activated carbon manufacturing plant requires careful planning and configuration of a series of professional equipment. This article will introduce the core equipment and functions of the activated carbon production line in detail to help you fully understand the entire production process from raw material processing to finished product packaging.

Raw Material Handling System

The raw material handling system is the first step in the activated carbon manufacturing process. This system ensures the efficient and continuous transfer of raw materials to subsequent processing stages.

Conveyor: Efficiently transport raw materials to ensure continuous operation of the production line. High-quality conveyors are designed to handle various types of biomass materials, ensuring smooth and consistent flow. They can be customized to include dust containment features to minimize environmental impact during transportation.

Crusher: Crush the raw materials to the appropriate size and equip with dust removal equipment to reduce dust. Crushers are crucial for breaking down large biomass pieces into smaller fragments that are easier to process. Advanced crushers also feature adjustable settings to control the output size, maximizing flexibility for different raw materials.

Grinding Equipment: Further refine the raw materials and improve the efficiency of subsequent processing. Grinding equipment, such as hammer mills and roller mills, converts raw biomass into fine particles. This step is essential for optimal carbonization and activation, as finely ground materials have a larger surface area that enhances chemical reactions.

Drying System

The drying system is critical for preparing raw materials for carbonization reducing their moisture content to optimal levels.

Drum Dryer: Control the moisture content of the raw materials to prepare for carbonization. Drum dryers offer continuous, efficient drying through direct or indirect heating methods. They are designed to handle large volumes of biomass, ensuring uniform moisture reduction.

Dust Removal Equipment: Reduce dust emissions during the drying process. Effective dust removal systems, such as cyclones and bag filters, capture fine particulate matter generated during drying. This ensures a cleaner working environment and compliance with environmental regulations.

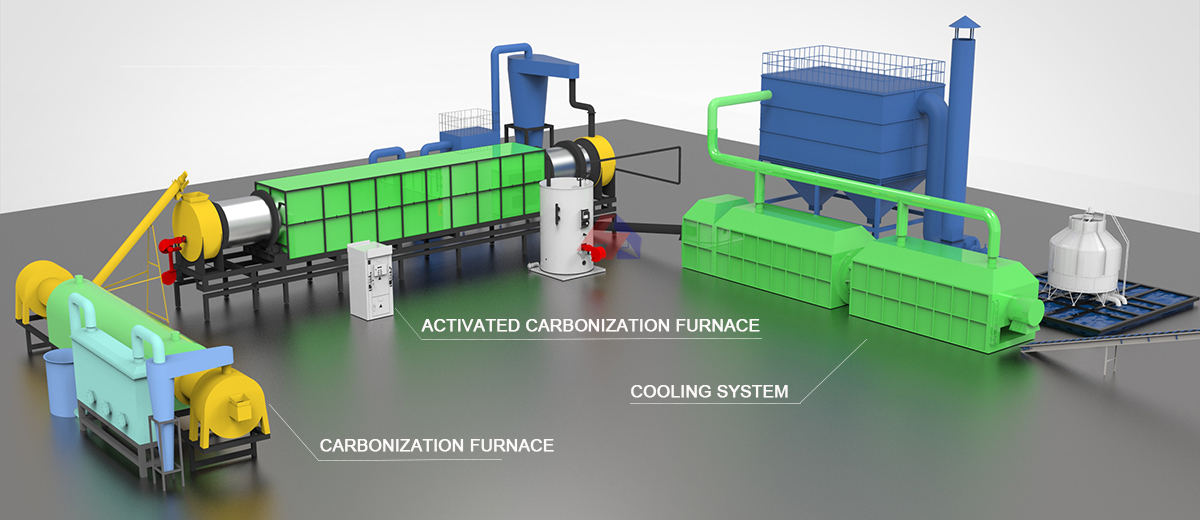

Carbonization System

The carbonization system converts dried biomass into charcoal through controlled heating in an oxygen-limited environment.

Continuous Carbonization Furnace: Core equipment that converts dry raw materials into charcoal. Continuous furnaces allow for high-capacity, uninterrupted carbonization. They maintain temperature control and uniform heating, which are essential for producing high-quality charcoal.

Condensation Dust Removal Equipment: Treat dust, gas, and tar generated during carbonization. These systems include condensers and scrubbers that capture volatile compounds, ensuring clean exhaust emissions and recovering valuable by-products.

Recycling Equipment: Collect and store valuable by-products (such as wood vinegar). Recycling systems ensure that by-products like bio-oil and wood vinegar are efficiently separated and stored for further use or sale, enhancing the overall economic viability of the plant.

Activation SystemThe activation system enhances the porous structure of charcoal, transforming it into activated carbon with a high surface area and absorption capacity.

Activated Carbon Furnace: High-temperature pyrolysis of charcoal to generate porous activated carbon. Activation furnaces use steam or chemical agents to develop the porous. They are designed to achieve precise control over activation conditions, ensuring consistent product quality.

ensation Dust Removal Equipment: Treat exhaust gas and dust during activation. These systems ensure that emissions from the activation process are minimized, capturing fine particles and gases to maintain environmental standards.

Finished Product Handling System

After activation, the handling system processes the activated carbon into sellable products.

Cooling Equipment: Reduce the temperature of newly generated activated carbon. Cooling equipment, such as rotary coolers or fluidized bed coolers, quickly lowers the temperature of activated carbon, preventing thermal degradation and improving handling safety.

Packaging Equipment: Quantitative packaging according to demand (10KG-50KG or custom weight). Advanced packaging systems ensure precise dosing and secure packaging of activated carbon products, facilitating easy storage and transportation.

Storage Facilities: Ventilated and dry warehouses with complete fire protection facilities. Proper storage is crucial for maintaining the quality of activated carbon. Facilities should be designed to prevent moisture ingress and include fire safety measures to handle the flammable nature of the product.

Special Processing Equipment

Special processing equipment allows for the customization of activated carbon products to meet specific market demands.

Kneading Granulation Equipment: Produce activated carbon products of specific shapes and sizes. This equipment ensures uniformity in dimensions, which is essential for applications requiring precise particle sizes.

ing Equipment: Ensure uniform particle size of finished products. Screening machines sort and classify activated carbon particles, ensuring consistent quality and performance in their intended applications.

Auxiliary Equipment

Auxiliary equipment supports the main production processes, ensuring smooth and efficient operations.

Belt Conveyor and Elevator: Full-line material transportation. These systems facilitate the movement of materials between different stages of production, enhancing workflow efficiency.

Fan: Auxiliary ventilation and material transportation. Fans play a critical role in maintaining optimal air flow and temperature control within the production environment.

** Gas Incinerator: Treat waste gas in production process and reduce environmental impact. Incinerators ensure that any residual gases are safely combusted, minimizing the release of harmful emissions.

Automation Control System

An advanced automation control system optimizes the entire production process, enhancing efficiency and product quality.

PLC Control System: Optimize production processes, improve efficiency, and product quality. Programmable Logic Controllers (PLC) provide precise control over manufacturing operations, enabling automation of complex tasks and real-time adjustments.

Monitoring Equipment: Real-time monitoring of production parameters to ensure safe production. Continuous monitoring systems track critical variables such as temperature, pressure, and levels, ensuring compliance with safety and quality standards.

The Importance of Choosing High-Quality Equipment

Investing in high-quality activated carbon production equipment can significantly improve production efficiency and product quality, reduce energy consumption, and minimize environmental pollution. This enhances the competitiveness and sustainability of enterprises.

Henan Hengju Machinery Equipment Co., Ltd. specializes in the research, development, and manufacturing of activated carbon production equipment, offering comprehensive solutions from single machines to complete production lines. Our equipment boasts the following advantages:

High Efficiency: Optimized design improves production efficiency.

Energy Saving and Environmental Protection: Advanced technology reduces energy consumption and emissions.Intelligent: Equipped with automated control systems for easy operation and management.

Customization: Provides personalized solutions to meet customer needs.

Comprehensive Service: Offers full technical support from equipment selection to installation and commissioning.

If you are planning to establish or upgrade an activated carbon production line, please contact Henan Hengju Machinery Equipment Co., Ltd. Our professional team will provide the most suitable equipment configuration suggestions and comprehensive technical support, helping you succeed in the activated carbon industry.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/what-activated-carbon-production-equipment-do-i-need-to-buy-to-open-an-activated-carbon-manufacturing-plant.html