Comprehensive Guide to Activated Carbon Carbonization Furnaces: Key Factors for Choosing a Quality Machine

Looking for a high-quality Activated Carbon Carbonization Furnace? Hengju Machinery, with years of experience, explains the carbonization principle, furnace types, and selection criteria. Discover our Activated Carbon Making Machines to boost your production efficiency and product quality.

Activated carbon, a seemingly simple yet complex black porous material, plays a vital role in modern industry and daily life. From purifying drinking water to treating air, from pharmaceuticals and food processing to gold extraction, activated carbon's exceptional adsorption capacity makes it indispensable in numerous applications. To produce high-quality activated carbon, the critical first step—carbonization—relies on a fundamental piece of equipment: the Activated Carbon Carbonization Furnace.

For investors and businesses planning to enter the activated carbon production field or upgrade existing facilities, gaining a deep understanding of the function, types, and selection process for a quality carbonization furnace is the cornerstone of project success. Drawing on our extensive industry knowledge and practical experience, Hengju Machinery is here to guide you. This article will provide a comprehensive analysis of activated carbon carbonization furnaces and offer key insights for choosing a premium Activated Carbon Carbonization Furnace.

The Foundation of Activated Carbon: Understanding Carbonization and Its Core Role in Production

Activated carbon's powerful adsorption capability stems from its highly developed pore structure and immense surface area. These characteristics are not naturally present in the raw material but are formed through a series of complex physical and chemical processes. Among these, "carbonization" is the foundational step that builds the carbon framework.

Activated carbon production typically involves two main stages:

Carbonization: Heating carbon-containing organic raw materials (such as wood, bamboo, coconut shells, coal, petroleum coke, etc.) in an oxygen-deficient or oxygen-free environment (pyrolysis). The goal is to remove moisture and volatile organic compounds, leaving behind a solid carbon skeleton. This high-temperature process is carried out within an Activated Carbon Carbonization Furnace.

Activation: The carbonized material undergoes further treatment in an activation furnace with activating agents (like steam, CO2, or chemicals) at even higher temperatures. This process etches and expands the pore structure, significantly increasing the surface area.

Evidently, the performance of the carbonization furnace directly dictates the quality of the carbonized product, which in turn affects the effectiveness of the subsequent activation and the quality and yield of the final activated carbon. An efficient, stable Activated Carbon Carbonization Furnace is the bedrock of the entire activated carbon production line.

This guide details each step, from raw material processing to final product quality assurance, emphasizing efficiency and innovation in activated carbon manufacturing.

In-Depth Analysis: The Principle of Activated Carbon Carbonization Furnaces and Hengju Machinery's Innovations

The core principle of an activated carbon carbonization furnace is to utilize external or internal heating to induce pyrolysis of the raw material in a strictly controlled, oxygen-deficient atmosphere. Based on different process requirements and material characteristics, common furnace types include:

Vertical Carbonization Furnace: Often operates continuously, suitable for granular or lump raw materials. Features a compact structure and relatively high energy utilization efficiency.

Horizontal Carbonization Furnace: Widely applicable, can handle various material forms. Includes the rotary kiln type, ideal for large-scale continuous production where material tumbling ensures more uniform heating.

At Hengju Machinery, building upon traditional furnace designs, we have incorporated decades of R&D and practical experience to introduce numerous optimization innovations, ensuring our Activated Carbon Carbonization Furnaces deliver superior performance:

Unique Furnace Chamber Structure: Optimized heat distribution ensures uniform material heating, minimizes dead zones, and improves carbonization rate and product consistency.

Advanced Sealing Technology: High-efficiency sealing for the furnace body and feed/discharge points maintains an oxygen-free or slightly negative pressure environment within the furnace, effectively preventing air leakage and oxidation, thereby boosting carbonization efficiency and safety.

Intelligent Temperature Control System: Precisely monitors and regulates temperatures in different zones of the furnace. It allows for setting optimal carbonization curves tailored to different raw materials and process requirements, guaranteeing the depth and quality of carbonization.

Eco-Friendly & Energy-Saving Design: Integration of high-efficiency flue gas collection and treatment systems (such as secondary combustion, waste heat recovery) allows the combustible gases produced during pyrolysis to be recycled as fuel for furnace heating. This significantly lowers operating costs and minimizes environmental impact.

These innovative designs stem from our deep understanding of the carbonization process and analysis of extensive real-world operating data, aiming to provide clients with carbonization solutions that are both environmentally compliant and economically beneficial.

Key Factors for Choosing a Quality Activated Carbon Carbonization Furnace: Hengju Machinery's Professional Insight & Practical Experience

Selecting a carbonization furnace is not merely purchasing a piece of equipment; it's choosing a production capability and securing a long-term partnership. Based on Hengju Machinery's years of experience serving clients worldwide, we believe the following key factors are essential considerations when selecting your Activated Carbon Carbonization Furnace:

Raw Material Adaptability & Customization Capability: Different raw materials (like coconut shells, wood, bamboo, various coal types) have specific requirements for furnace type and process parameters. Hengju Machinery provides professional analysis and customized equipment solutions based on your specific raw material, ensuring the equipment can efficiently process your target material.

Actual Capacity & Energy Consumption Performance: Beyond the stated capacity, focus on the actual stable output and energy consumption per unit of product when processing your specific raw material. Hengju Machinery's equipment emphasizes energy-saving design, aiming for higher charcoal yield with lower energy input. We can provide operational data references from relevant projects.

Equipment Reliability & Durability: Carbonization furnaces operate under high temperatures for extended periods, making material quality and manufacturing craftsmanship crucial. Key components of Hengju Machinery's furnaces utilize high-quality, high-temperature resistant, and anti-corrosion materials. We strictly adhere to industrial equipment manufacturing standards to ensure durable, stable operation with reduced downtime and maintenance costs.

Automation Level & Ease of Operation: An advanced automation control system can precisely manage process parameters, ease the operator's workload, and improve production stability. Hengju Machinery's equipment incorporates ergonomic design with user-friendly interfaces, making operation simple and easy to learn.

Safety Performance Design: High temperatures and flammable gases (like pyrolysis gas) are inherent in the carbonization process, making safety paramount. Hengju Machinery's carbonization furnaces are equipped with comprehensive safety interlocks, temperature/pressure monitoring, explosion protection devices, and other safety systems to ensure safe and reliable production.

Supplier Experience, R&D Strength & After-Sales Service: These are key indicators of a supplier's overall capability. Hengju Machinery has specialized in the activated carbon equipment field for decades, possessing a strong R&D team and a comprehensive after-sales service system. We provide end-to-end support, from project consultation, scheme design, equipment manufacturing, and installation & commissioning, to personnel training, spare parts supply, and timely remote guidance, ensuring your production line starts smoothly and operates stably long-term.

Hengju Machinery's Practical Experience: Boosting Activated Carbon Production Efficiency & Product Quality

Providing the equipment is only part of the equation; the real value lies in helping clients transform that equipment into efficient production capabilities and high-quality products. Hengju Machinery has accumulated extensive process experience through years of practice, enabling us to offer clients:

Process Optimization Advice: Provide recommendations for optimal carbonization temperature, holding time, heating rate, and other process parameters tailored to different raw materials and target products (e.g., wood-based charcoal, coconut shell charcoal, coal-based charcoal).

Troubleshooting and Problem Resolution: With our in-depth knowledge of the equipment, we can quickly diagnose and resolve potential operational issues, minimizing downtime.

Remote and On-site Technical Support: Ensure stable and efficient equipment operation through remote monitoring, technical guidance, or dispatching engineers for on-site service.

Seamless Integration with Activation Process: As a professional Activated Carbon Making Machine supplier, we are also experts in the subsequent activation process. We can provide optimal integration solutions between the carbonization and activation stages, ensuring the entire production line is coordinated and efficient.

Our experience demonstrates that a well-designed, stable-running Activated Carbon Carbonization Furnace, combined with optimized processes and professional service, can increase carbonization yield by 5%-10% and provide higher-quality carbonized material for subsequent activation. This directly leads to a significant improvement in the final activated carbon's adsorption performance (for example, iodine adsorption value can increase by 100-200 mg/g).

Your Complete Solution: More Than Just a Furnace - The Hengju Machinery Activated Carbon Making Machine Overview

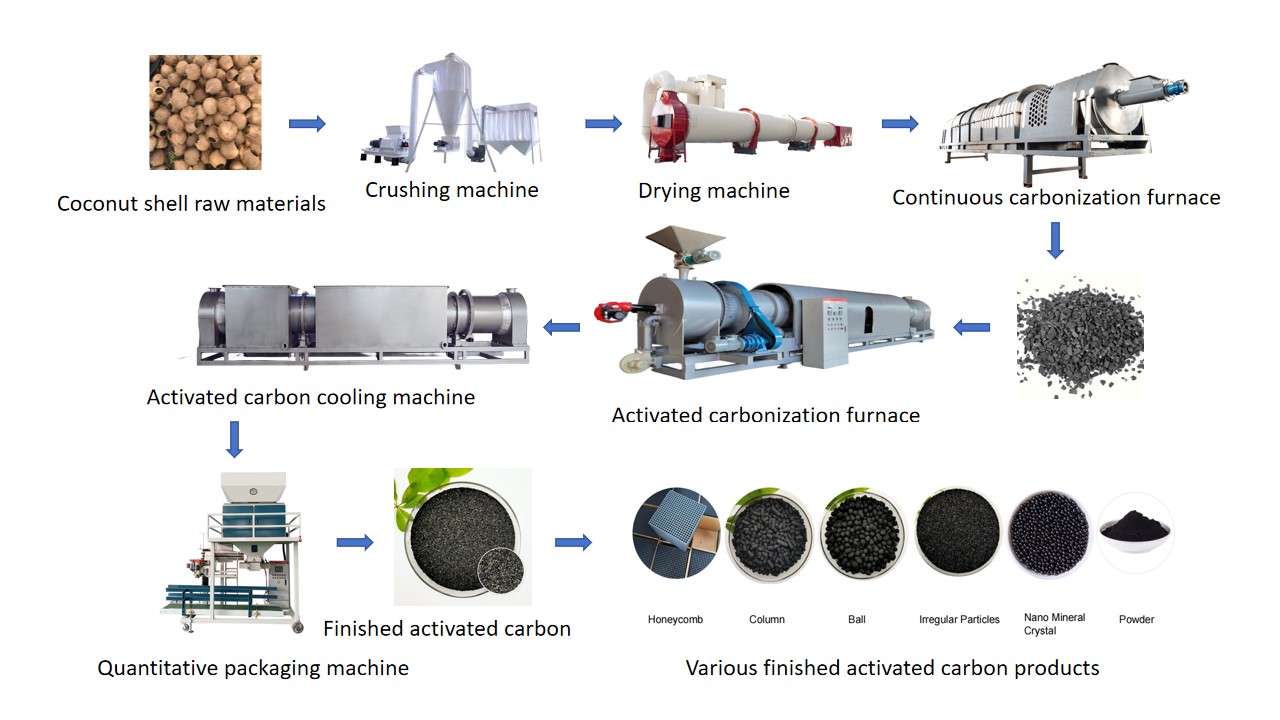

While the Activated Carbon Carbonization Furnace is a core component, it's just one piece of the puzzle in building an efficient activated carbon production line. A complete Activated Carbon Making Machine or Activated Charcoal Making Machine line typically includes raw material crushing, drying, carbonization, cooling, activation, crushing & screening, dust collection, packaging, and other stages.

Hengju Machinery not only focuses on manufacturing high-quality Activated Carbon Carbonization Furnaces; we are fully capable of providing complete activated carbon production line solutions. From initial project planning and design to the manufacturing and integration of the entire set of equipment, followed by installation, commissioning, and post-sales service, we offer a one-stop solution. Choosing Hengju Machinery as your Activated Carbon Making Machine supplier means you benefit from:

Overall Optimized Design: Ensures seamless integration and efficient flow between all stages of equipment.

One-Stop Procurement and Service: Simplifies the purchasing process and avoids the complexities of coordinating multiple suppliers. All issues can be resolved through Hengju Machinery.

Professional Guidance Based on Integrated Process: Our engineers have a deep understanding of the entire production line and can provide more comprehensive technical support.

To learn more detailed information about the high-quality Activated Carbon Carbonization Furnaces and complete Activated Carbon Making Machine solutions offered by Hengju Machinery, including specifications for different models, technical advantages, and customer case studies, please visit our official product page:

Why Choose Hengju Machinery? Our Strength and Commitment

Since its establishment, Hengju Machinery has consistently focused on the R&D, manufacturing, and service of activated carbon production equipment and related thermal processing machinery. We understand that equipment quality and technological innovation are the foundations of a company's survival and development.

Extensive Industry Experience: With decades of equipment manufacturing and service experience, we understand industry pain points and command core technologies.

Strong R&D Capabilities: Continuous investment in research and development allows us to constantly optimize equipment performance and hold numerous patented technologies.

High-Standard Manufacturing: Modern factory, sophisticated processing equipment, and a rigorous quality control system ensure that every machine leaving our facility meets international standards.

Global Customer Recognition: Our products are exported to numerous countries and regions, earning widespread recognition from clients worldwide.

Comprehensive Pre-sales and After-sales Service: From initial consultation to equipment lifetime maintenance, we provide a full process, high-efficiency service support.

Choosing Hengju Machinery means choosing a trustworthy partner. We are committed to helping you achieve remarkable success in the activated carbon production field through our professionalism, quality, and service.

Activated carbon making machine operation demo video

Conclusion: Make a Smart Choice for Your Activated Carbon Carbonization Furnace, Grow with Hengju Machinery

The Activated Carbon Carbonization Furnace is the "heart" of the activated carbon production line. Investing in a high-quality, efficient, and reliable Activated Carbon Carbonization Furnace is key to ensuring your product quality, increasing production efficiency, and lowering operating costs. When evaluating equipment, be sure to consider the supplier's practical experience, technical strength, equipment performance, environmental compliance, and after-sales service capabilities.

Hengju Machinery, with its deep industry accumulation, continuous technological innovation, and profound understanding of customer needs, is capable of providing you with the most suitable Activated Carbon Carbonization Furnace and complete Activated Carbon Making Machine solutions. We look forward to partnering with you to build an efficient, eco-friendly, and profitable activated carbon production line.

If you are planning to invest in activated carbon production equipment or need to upgrade your existing carbonization equipment, do not hesitate to contact Hengju Machinery. Our professional team is ready to provide you with the highest quality equipment and the most comprehensive solutions.

Take Action Now! Visit Our Product Page to Learn More or Contact Us for a Custom Quote!

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/activated-carbon-carbonization-furnace-guide--hengju.html