The difference between ring die pellet machine and flat die pellet machine

In the biomass pellet fuel production and feed processing industries, ring die pellet machine and flat die pellet machine are two common pelletizing equipment. They each have different structures and working principles, suitable for different production needs.

1. Structural difference

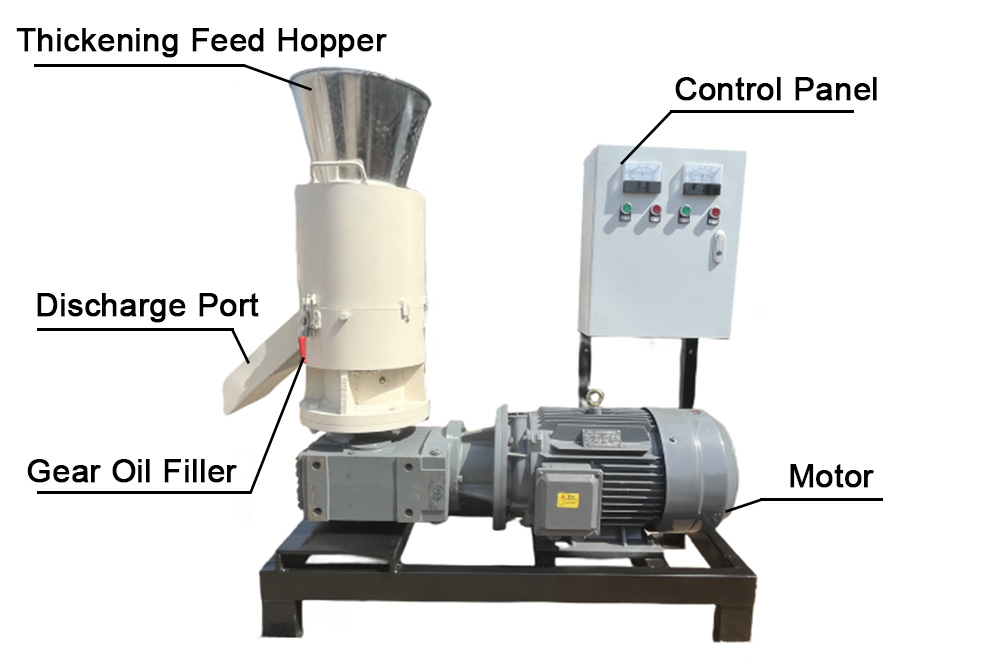

The ring die pellet machine uses a circular ring-shaped die, the outer ring of the die is full of die holes, and the pressure roller rotates inside the die and squeezes the material through the die holes. The die of the flat die pellet machine is flat, the pressure roller rotates above or below the die, and the material is squeezed out of the die hole.

2. Scope of application

The ring die pellet machine is suitable for large-scale industrial production, such as the processing of high-hardness raw materials such as wood chip pellets, biomass fuels, and feed. The flat die pellet machine is suitable for small-scale production and is often used for agricultural feed pellets, especially for raw materials with lower hardness.

3. Production efficiency

Due to the ring die structure, the ring die pellet machine has a strong production capacity and high particle density, which is suitable for long-term continuous operation. The single machine capacity is usually 1-20 tons/hour. The production capacity of the flat die pellet machine is relatively low, generally between 100 kg and 1 ton/hour, which is suitable for small batch production.

4. Pellet density

The pellets produced by the ring die pellet machine have a higher density, high strength, and higher combustion efficiency, which are suitable for high-quality fuel or feed production. The pellet density produced by the flat die pellet machine is relatively low, which is suitable for industries that do not have excessive requirements for pellet density.

Ring die pellet machines and flat die pellet machines each have their own advantages. Users should choose the appropriate equipment according to their own production needs, investment budget and target market. If you need to produce high-density biomass pellets or industrial feed on a large scale, the ring die pellet machine is a better choice. If the production scale is small, the funds are limited or the main processing is soft raw materials, the flat die pellet machine is a more economical solution.

Whether you choose a ring die pellet machine or a flat die pellet machine, Hengju Machinery can provide you with high-quality and well-designed machines. Our factory has more than 30 years of equipment manufacturing experience, and the ring die pellet machines and flat die pellet machines manufactured are exported all over the world.

If you have any questions about the ring die pellet machine and the flat die pellet machine, please contact Hengju Machinery, our professional engineers can answer you.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/the-difference-between-ring-die-pellet-machine-and-flat-die-pellet-machine.html