Is charcoal manufacturing profitable?

1. Analysis of charcoal market demand

Charcoal has a wide range of applications and the market demand is growing steadily. In many developing countries, charcoal is still the main source of household fuel, especially in areas with insufficient electricity supply or high energy prices, where residents are highly dependent on charcoal.

In addition, the barbecue industry has a strong demand for high-quality charcoal, especially in the Middle East and European markets, where high-quality charcoal is favored for its stable combustion, smokeless and odorless properties.

In terms of industrial use, charcoal is widely used in many fields such as metallurgy, activated carbon production and agricultural soil improvement, further promoting the growth of market demand.

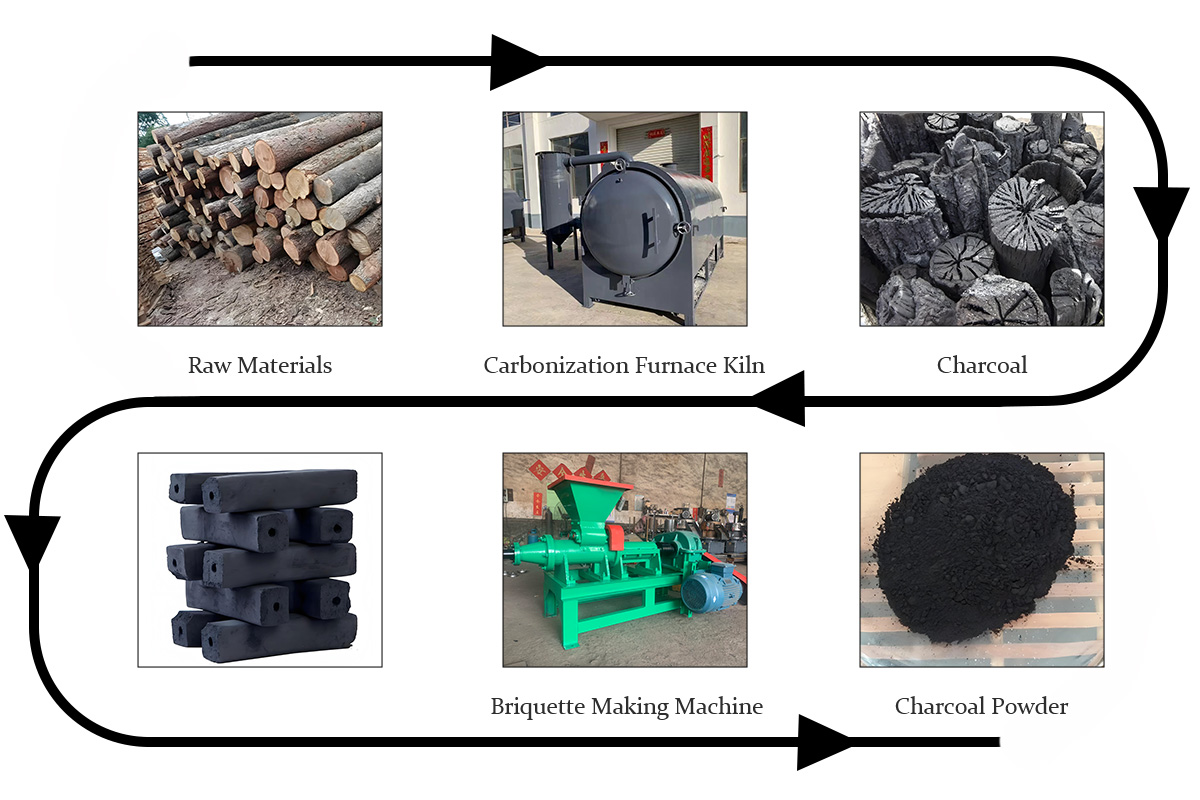

2. Analysis of charcoal production costs

The cost of charcoal manufacturing is mainly composed of raw materials, equipment investment, labor, electricity and environmental protection treatment costs.

If companies can obtain low-cost biomass raw materials such as sawdust, wood chips, and coconut shells, they can reduce expenses in the production process and increase profit margins.

In terms of equipment investment, the price of charcoal machines varies depending on production capacity and degree of automation. Small equipment investment is usually between $5,000-$15,000, while medium and large production lines may exceed $50,000.

Energy consumption is also an important part of the cost. Modern charcoal production lines use pyrolysis technology to reduce energy consumption and improve charcoal conversion rate.

3. Profit margin of charcoal manufacturing

The profitability of charcoal manufacturing depends on product quality, market price and production efficiency.

Generally speaking, the cost of raw materials per ton is about $50, and it takes about 2.5 tons of raw materials to produce 1 ton of charcoal, so the cost of raw materials is about $125/ton. In the market, the price of ordinary charcoal is $300-$600/ton, and high-quality machine-made charcoal can even reach $800/ton.

Even considering the costs of labor, electricity, equipment depreciation, etc., the profit per ton of charcoal can still reach $150-$400, which is relatively considerable.

4. Key influencing factors

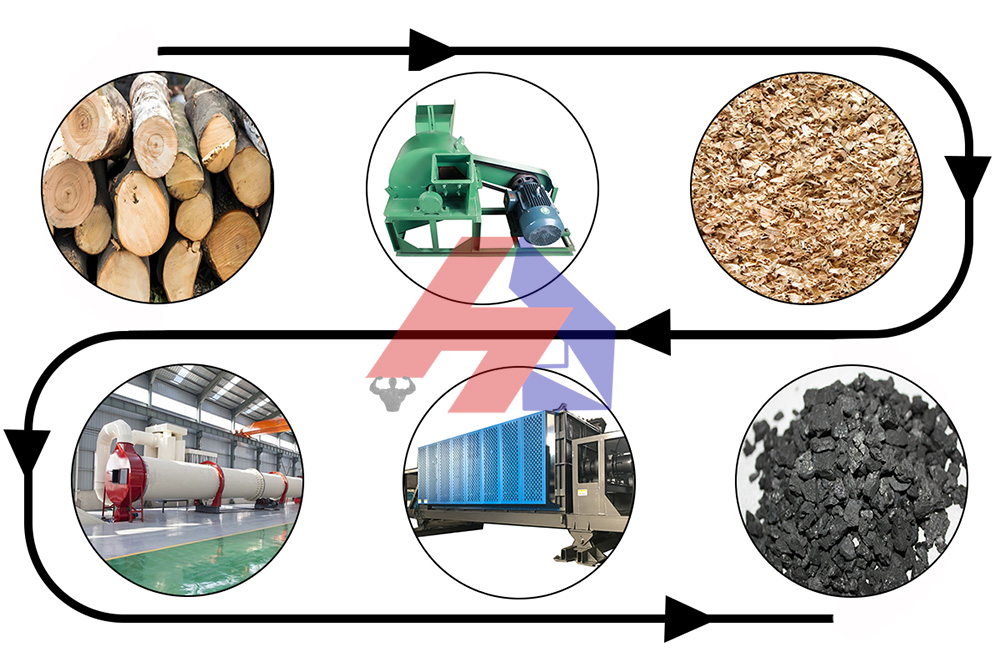

The profitability of charcoal manufacturing is affected by many factors, and market positioning is one of the key factors. High-end machine-made charcoal has higher profits, but has stricter requirements on equipment and production technology. The charcoal making machine produced by Hengju Machinery can easily produce high-quality charcoal.

Hengju Machinery's charcoal making machine adopts a fully automatic manufacturing method, which can continuously and high-quality charcoal. The charcoal produced is more expensive and has a larger profit margin. Moreover, a good charcoal making machine has a longer service life and lower later repair and maintenance costs.

If you are also interested in charcoal manufacturing or charcoal making machines, please contact Hengju Machinery, and our professional engineers will answer your questions.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/is-charcoal-manufacturing-profitable.html