Can shredders handle scrap metals of different sizes and types?

As an important equipment in scrap metal processing, shredders can efficiently handle scrap metals of different sizes and types. Whether it is hard iron and steel, or soft aluminum and copper, shredders can quickly crush and process them through suitable blades and working principles.

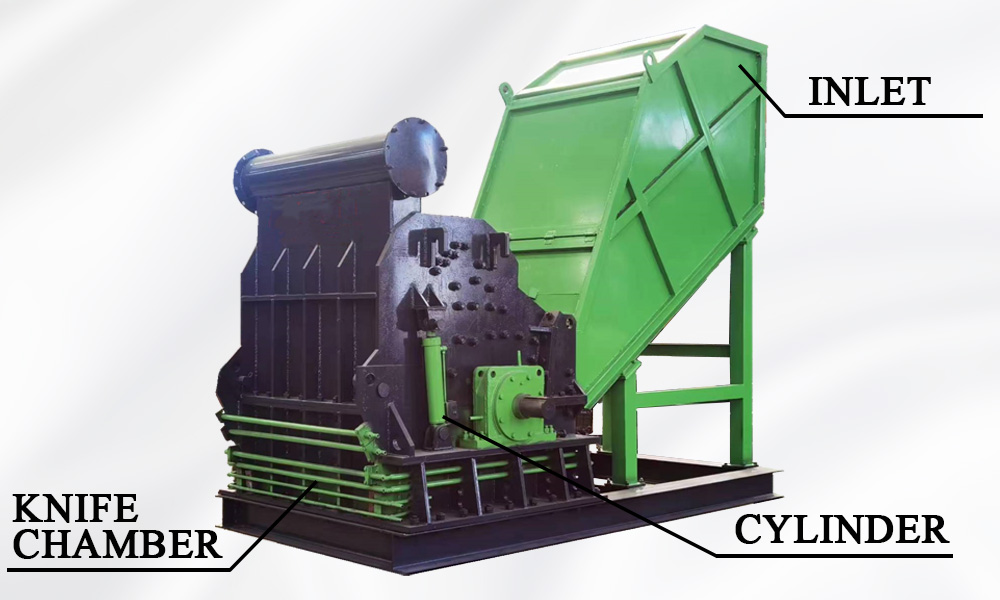

Working principle of shredders

The shredder tears the scrap metal materials into smaller pieces through two sets of high-speed rotating blades or gears. This process is not only a mechanical crushing of the scrap metal, but also accompanied by the action of multiple forces such as tearing, compression and twisting, so that the scrap metal is effectively decomposed and processed. So what factors affect the processing capacity of the shredder?

1. Types of metals:

Iron and steel: For common iron, steel and other hard metals, shredders can handle them efficiently, but models equipped with high-strength blades need to be selected. These metals usually require greater force and longer crushing time to successfully tear them into smaller pieces. For lighter scrap metals such as aluminum alloys, the shredder blades can cut them relatively easily.

2. Size of scrap metal:

The size of scrap metal directly affects the processing capacity of the shredder. For large scrap metals, such as car shells, mechanical parts, etc., the shredder needs to have a strong initial crushing capacity, and the blade spacing needs to be properly adjusted so that large pieces of material can be processed efficiently.

3. Mixed materials:

Shredders can not only process a single type of metal, but also mixed scrap metals, such as scrap containing impurities such as plastic, rubber, and wood. This type of mixed material is more difficult to handle because in addition to metal, other materials need to be removed and separated. At this time, it is very important to choose a shredder suitable for processing mixed waste, which usually requires stronger blade wear resistance and higher cutting force.

The design of the shredder allows it to be highly flexible in processing different types and sizes of scrap metal. Many modern shredders are equipped with an adjustable blade spacing function, which can adjust the shredding force and particle size according to the size of the scrap metal.

The shredders produced by Hengju Machinery can handle various types and sizes of non-metals, and can be customized according to the unique needs of customers. If you have any questions about shredders, you can consult Hengju Machinery.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/can-shredders-handle-scrap-metals-of-different-sizes-and-types.html