Can biomass pellet machines be customized to meet specific needs?

With the diversification and personalization of market demand, many companies have begun to seek customized biomass pellet machines to meet specific production requirements. Then of course, biomass pellet machines can be customized to meet specific needs. For example, Hengju Machinery provides customized services for biomass pellet machines.

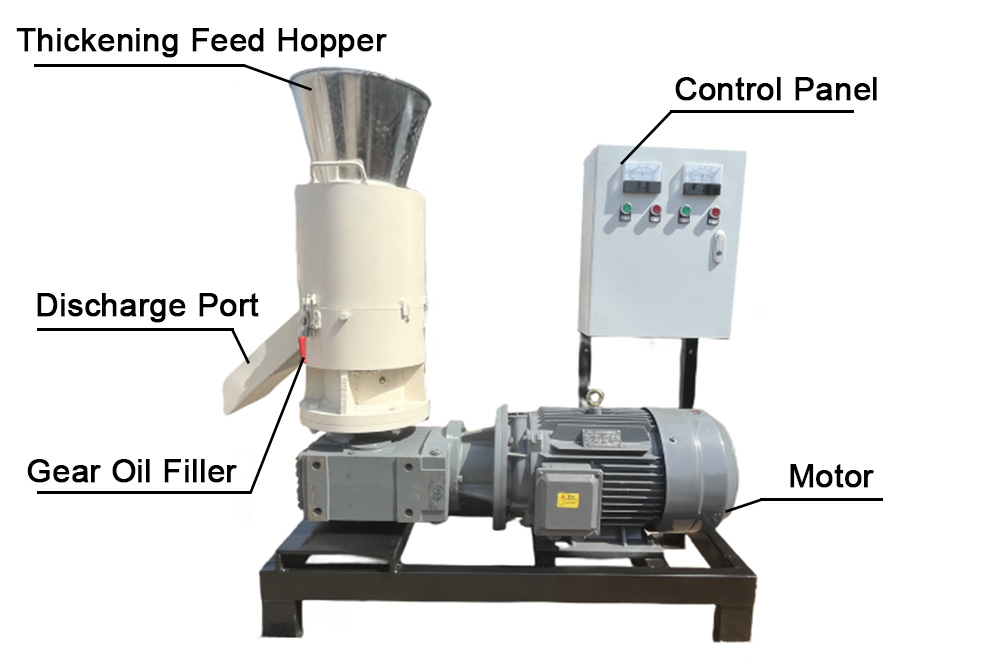

The basic components of biomass pellet machines usually include feeding systems, pressing rollers, molds, drive devices, and electronic control systems. Standardized biomass pellet machines are usually able to handle a certain range of raw materials, such as wood chips, rice husks, straw, etc., and produce pellet fuels that meet standards.

Different companies have different requirements for pellet fuels, such as the hardness, density, humidity, and even the appearance, size, and shape of the pellets. These requirements may need to be achieved through the customization of equipment.

Different types of biomass raw materials have different characteristics, which requires pellet machines to be designed specifically in the feeding system and pressing system to ensure that specific raw materials can be handled smoothly.

Depending on the scale of production, the output capacity of the pellet machine will also vary. For large-scale production companies, customizing high-power pellet machines may be more suitable, while for small-scale production companies, customizing small equipment is required.

With increasingly stringent environmental regulations, many companies hope to customize biomass pellet machines with higher energy efficiency and lower emissions. This usually involves optimizing the combustion efficiency of the equipment, reducing noise and dust emissions, etc.

The ways to customize biomass pellet machines mainly include the following aspects: changing the design of rollers and molds, adjusting the drive system and electronic control system, adding additional functions, customizing external accessories, etc.

When customizing biomass pellet machines, you need to pay attention to the manufacturer's qualifications and experience, and choose a manufacturer with rich customization experience and technical strength. At the same time, the repair and maintenance of customized equipment is relatively complicated, so it is particularly important to choose a manufacturer that provides perfect after-sales service. For example, Hengju Machinery not only has professional engineers to provide customized solution designs, but also has more than 30 years of experience in the industry. The customized biomass pellet machines it produces are sold all over the world, providing customers with stable quality and after-sales.

Customizing biomass pellet machines is completely feasible, and for many companies, customized equipment can better meet their specific production needs, improve production efficiency and pellet quality. Therefore, if you also have the need for customized biomass pellet machines, please feel free to contact Hengju Machinery. Through reasonable customization, companies can not only improve productivity, but also gain an advantage in the fierce market competition.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/can-biomass-pellet-machines-be-customized-to-meet-specific-needs.html