What kind of shredder should I choose to deal with scrap cars?

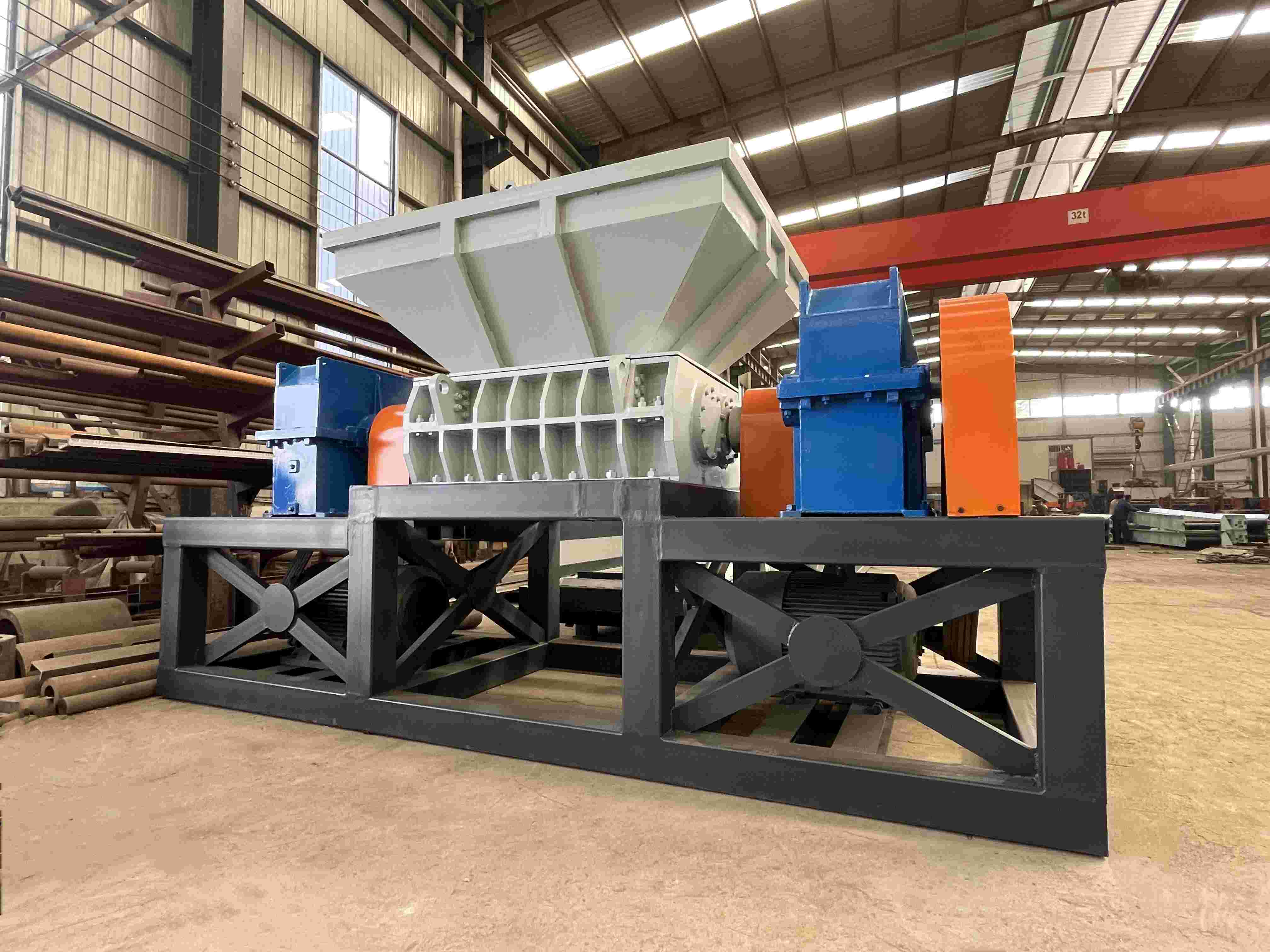

Dual-Shaft Shredders are rugged shredders that are widely used to process large, complex scrap items such as scrap cars. Compared to other types of shredders, dual-shaft shredders are the best choice for deal with scrap cars due to their versatility, low-speed high-torque characteristics and excellent durability.

The working principle of dual-shaft shredders is based on two parallel rotating shafts with multiple sets of cutting blades installed on them. When the material is fed into the shredder, these blades firmly grasp the material at a low speed and high torque, and shred the entire vehicle or large car parts into small pieces by rotating tearing and cutting.

Advantages of dual-shaft shredders:

1. Dual-shaft shredders are usually equipped with adjustable blade gaps and different types of blade combinations, which can flexibly cope with different types of scrap cars and their parts. This means that a variety of sizes and shapes of materials can be processed with simple adjustments to meet different recycling requirements. The output size can also be controlled by changing the blade and shredding settings to ensure the efficiency of subsequent metal separation and recycling.

2. Since the double-shaft shredder uses the shearing principle of low speed and high torque, it can generate huge tearing force at a lower speed. This design can not only effectively prevent the material from winding and clogging during the shredding process, but also prevent the equipment from overloading.

3. Unlike the high-speed hammer crusher, Hengju Machinery's double-shaft shredder runs at a low speed, which greatly reduces the noise and dust during operation. This is particularly important in industrial operating environments, because lower noise levels help create a healthier working environment while reducing the impact on the surrounding environment.

4. Hengju Machinery's double-shaft shredder blades are made of high-strength H-13, ensuring that they can maintain long-term durability when handling high-strength metal materials. At the same time, Hengju Machinery's double-shaft shredder blades wear slowly, and the equipment maintenance requirements are low, helping customers reduce downtime and maintenance costs.

Hengju Machinery's double-shaft shredder has become an ideal equipment for processing scrap cars recognized by many customers around the world for its versatility, durability and efficiency. Choosing Hengju Machinery's double-shaft shredder can significantly improve the recycling efficiency of scrap cars, reduce operating costs, and ensure that you maintain a competitive advantage in the fierce recycling industry.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/what-kind-of-shredder-should-i-choose-to-deal-with-scrap-cars.html