Difference between Industrial pyrolysis ovens and industrial pyrolysis furnaces

Industrial pyrolysis ovens and industrial pyrolysis furnaces are two common types of pyrolysis equipment. Although their basic principles are similar, there are significant differences in structure, working principles, and applications.

Structural features:

Industrial pyrolysis ovens are usually designed as closed boxes with a heating area inside, suitable for processing smaller materials. Its design allows materials to be heated evenly in the oven and is suitable for pyrolysis processes at lower temperatures.

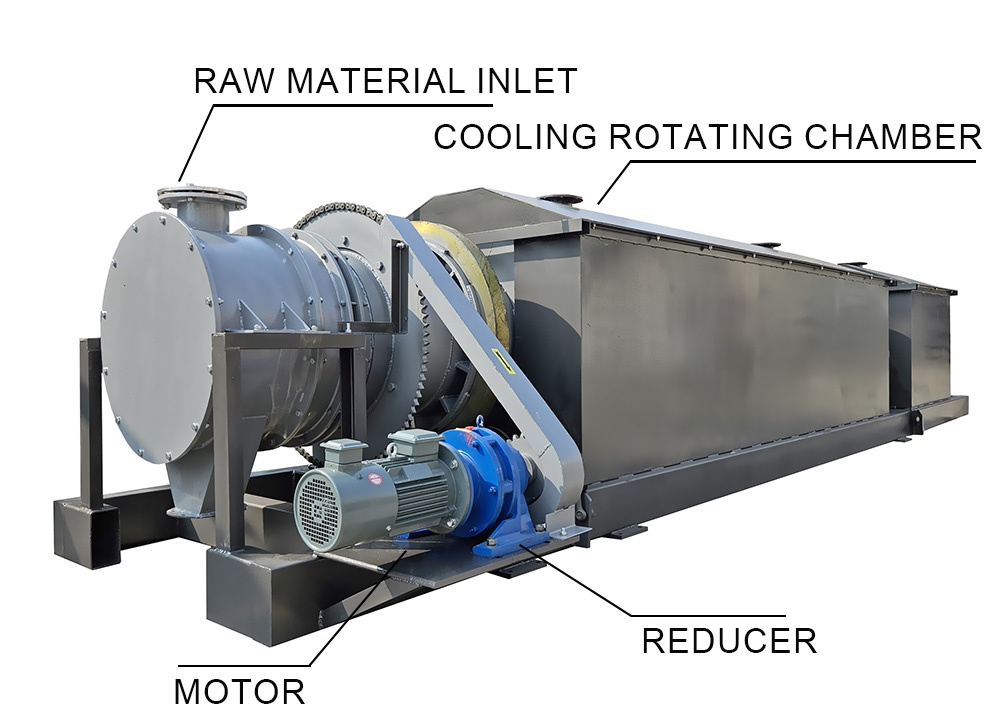

Industrial pyrolysis furnaces are usually designed as large-scale equipment suitable for processing bulk feedstocks. Its structure is more complex, including a feed system, reaction zone and gas treatment system.

Working principle:

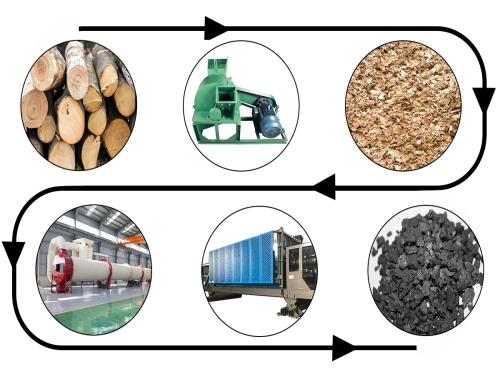

Industrial pyrolysis ovens can heat materials in the oven and begin to decompose after the water evaporates, producing gas, oil and solid residue. Due to the relatively mild heating, the gases and oils produced during pyrolysis may be of lower quality. Generally working between 200-600 degrees Celsius, suitable for the processing of biomass and certain plastics.

The materials in the industrial pyrolysis furnace decompose rapidly at high temperatures, and the reaction process is more violent. Due to the higher temperature, complex organic matter can be decomposed more effectively, resulting in higher quality gas and oil.

Usually working between 400-1000 degrees Celsius, it is suitable for the pyrolysis of a variety of organic wastes and polymer materials.

Application areas:

Industrial pyrolysis ovens are mainly used for small-scale waste processing, laboratory research or small production lines. It is suitable for occasions where the requirements for pyrolysis products are not high, such as the preliminary treatment of biomass fuel. Due to the limited processing capacity, it is suitable for low output requirements; but it is relatively low in product quality and efficiency.

Industrial pyrolysis furnaces are widely used in large-scale industrial waste treatment, energy recovery and material regeneration. Capable of handling a wide range of complex wastes such as plastics, rubber and municipal solid waste. Although the initial investment is high, it can improve pyrolysis efficiency and product quality, and is suitable for large-scale and high value-added industrial applications.

Therefore, if you want to manufacture a large-scale industrial production line and process a large variety of wastes at the same time, it is recommended that you choose an industrial pyrolysis furnace. Hengju Machinery has more than 30 years of production experience in the field of large-scale machinery production. The industrial pyrolysis furnaces produced have been developed and upgraded by a team of professional engineers for many times. They are high-quality, strong and durable equipment. Welcome to contact Hengju Machinery.

There are obvious differences between industrial pyrolysis ovens and industrial pyrolysis furnaces in structure, working principle and application fields. Industrial pyrolysis ovens are more suitable for small-scale processing and laboratory research, while industrial pyrolysis ovens are widely used in industrial fields due to their high efficiency and processing capabilities.

If you have any other questions about industrial pyrolysis ovens and industrial pyrolysis furnaces, please feel free to contact Hengju Machinery. Our professional engineers will answer your questions as soon as possible.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/difference-between-industrial-pyrolysis-ovens-and-industrial-pyrolysis-furnaces.html