Choosing the Right Activated Carbon Equipment: A Guide to Producing Activated Carbon from Bamboo

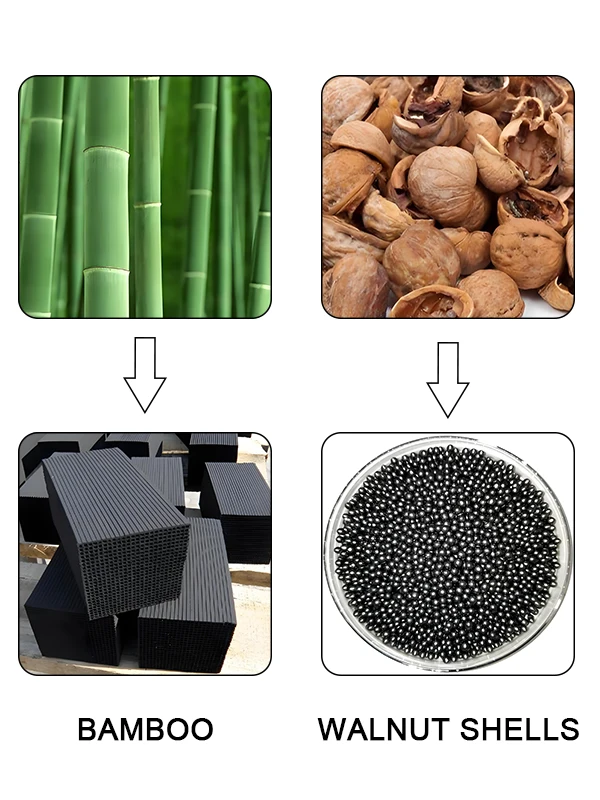

In the activated carbon production industry, selecting the right equipment is crucial. As an experienced writer, I will provide you with detailed information on the equipment needed to produce activated carbon from bamboo. Activated carbon is a high-surface-area carbon material with strong adsorption capabilities, widely used in water purification, air purification, pharmaceuticals, and food industries. Bamboo, as a renewable resource, has natural advantages as a raw material for activated carbon.

Equipment Selection for Producing Activated Carbon from Bamboo

When producing activated carbon from bamboo, it is essential to choose the right equipment to ensure product quality and production efficiency. The following are common types of activated carbon equipment:

Activated Carbon Activation Furnace: This is a critical piece of equipment in activated carbon production. The activation furnace uses high-temperature treatment to carbonize and activate the surface of bamboo, increasing its adsorption capacity. Hengju Machinery’s activated carbon activation furnace employs advanced technology to ensure product quality and production efficiency. For example, Hengju Machinery’s activation furnace can reach temperatures of up to 1200°C, ensuring the complete carbonization of bamboo.

Carbonization Furnace: The carbonization furnace is used to convert bamboo into carbon. It controls temperature and time to achieve the carbonization process. The selection of a carbonization furnace depends on factors such as bamboo type, production capacity, and carbonization temperature.

Crusher: The crusher is used to crush the carbonized bamboo into the desired particle size. The selection of a crusher depends on factors such as production capacity, particle size, and energy consumption.

The Importance of Equipment Selection

The importance of equipment selection cannot be overstated. Choosing the right equipment can ensure product quality, increase production efficiency, and reduce costs. For example, using Hengju Machinery’s activated carbon activation furnace can increase the adsorption capacity of activated carbon, achieving a purity of 99.9%.

Real-World User Feedback

“We have been using Hengju Machinery’s activated carbon equipment for two years, and the product quality has always been high. The equipment is stable and easy to maintain.” - A user from a US-based activated carbon production company

“Hengju Machinery’s activated carbon equipment has helped us increase production and quality while reducing costs. We are very satisfied with their service.” - A user from a Chinese activated carbon production company

Authority Endorsement

Hengju Machinery’s activated carbon equipment has obtained ISO9001 quality management system certification and complies with CE safety standards. Our equipment has gained widespread recognition globally. For example, Hengju Machinery’s activated carbon equipment is used by activated carbon production companies in the US, China, India, and other countries.

Hengju Machinery produces activated carbon equipment for clients with different needs worldwide. We can meet your various requirements for activated carbon activation furnaces and have rich production experience. If you have any questions about activated carbon production equipment, please consult Hengju Machinery. We will provide you with professional service and support.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/choosing-the-right-activated-carbon-equipment-a-guide-to-producing-activated-carbon-from-bamboo.html