Which equipment is included in the activated carbon production line?

Activated carbon is made of high-quality coal, sawdust, fruit shell, coconut shell and other materials as raw materials, and is refined by advanced carbonization process and activated pyrolysis process. In recent years, more and more people have seen the commercial value of activated carbon, so which equipment is included in the activated carbon production line? Hengju Machinery Equipment will introduce it to you in detail.

Crushing equipment: crush the raw materials for making activated carbon into suitable sizes.

Drying equipment: evaporate the excess water inside the raw materials, rotary structure, high drying efficiency and good drying effect.

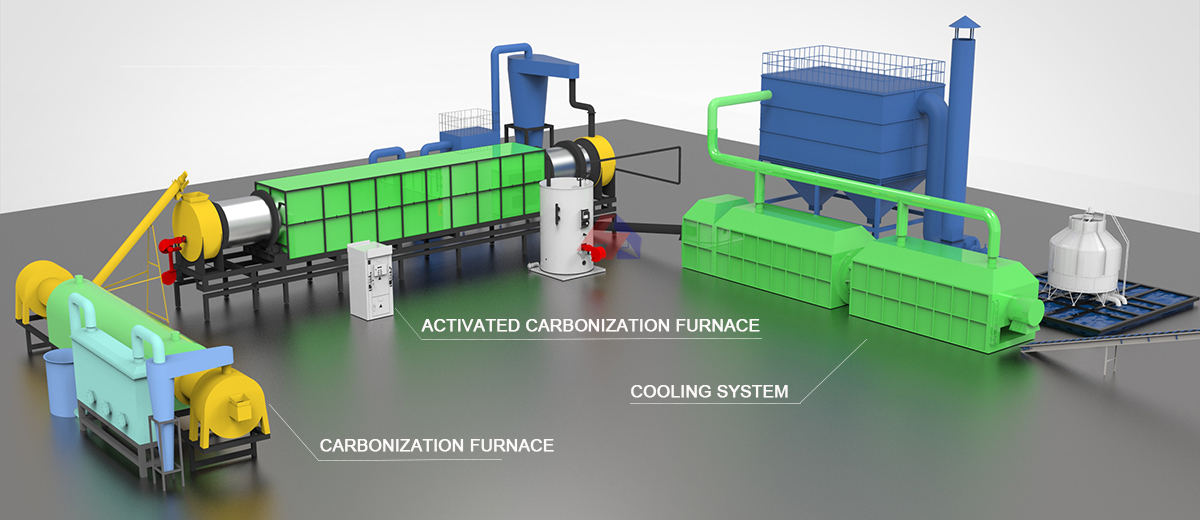

Continuous carbonization furnace: Unlike traditional kilns, continuous carbonization furnaces can continuously feed and discharge materials, greatly improving production efficiency. The high-temperature gas generated during the production process can also be recycled and reused to reduce energy loss.

Activated carbon furnace: The appearance is similar to the carbonization furnace, which pyrolyzes the carbon material, opens the adsorption holes, and finally transforms it into a continuous rotary furnace for activated carbon. The activated carbon furnace has an integrated rotary structure, is not easy to deform, and the activated carbon produced has a high iodine value and good adsorption.

Circulating water cooling equipment: Using circulating water to cool the manufactured activated carbon can reduce the ash content of activated carbon, increase output, and improve production efficiency.

Quantitative packaging equipment: Quantitatively package the finished activated carbon according to the standard to facilitate transportation and sales. The quantitative packaging machine uses computer intelligent weighing, with high accuracy and small error.

Therefore, the activated carbon production line mainly includes equipment: crushing equipment, continuous carbonization furnace, activated carbon furnace, circulating water cooling equipment and quantitative packaging equipment. Of course, if you have special requirements for the activated carbon products produced, you can also consult Hengju Machinery's professional engineers. We provide personalized customization services for each customer.

Hengju Machinery has more than 30 years of experience in the field of activated carbon production lines, with customers all over the world. Please feel free to contact us

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/company-news/which-equipment-is-included-in-the-activated-carbon-production-line.html