What factors should be considered when choosing a shredder?

When choosing a shredder, you need to fully evaluate the material characteristics, production capacity, output requirements, equipment durability and environmental performance to ensure that the selected equipment not only meets the current needs.

1. Different material types

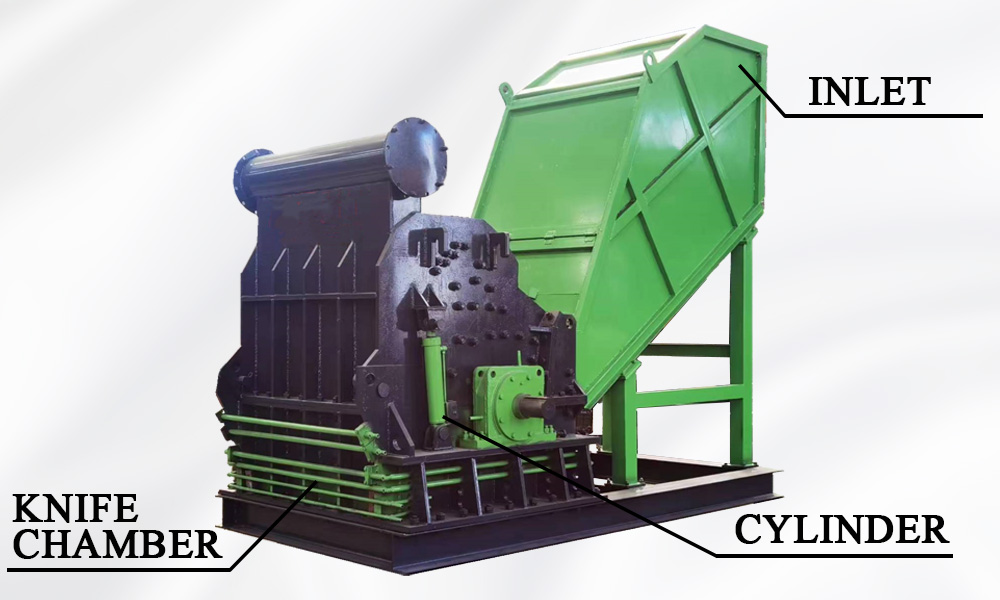

The hardness, density and size of the material directly determine the material and design requirements of the shredder blade. Harder or denser materials require more durable blades, while large-sized materials require wider feed ports and larger shredding chambers to ensure smooth operation.

2. Processing capacity

The processing capacity is mainly reflected in whether the shredder's hourly or daily throughput can meet the needs of the production line. If the equipment's processing capacity is insufficient, it may lead to low production efficiency; and choosing too large equipment will increase unnecessary investment and operating costs. Therefore, it is key to choose the right model according to your own production scale.

3. Output requirements

Depending on the purpose, some processes may require a finer particle size, while other applications do not have too high requirements for the output size. Therefore, when purchasing, it should be clear whether the shredder's grading capacity can meet the requirements of subsequent processes. If finer output is required, you can consider whether an additional screening system or secondary crushing equipment is needed.

4. Durability and maintenance costs

High-quality shredders usually use more wear-resistant blades and a more robust body design, which increases the life of the equipment and reduces the frequency of maintenance. In addition, you should also understand the replacement cost and availability of spare parts, which directly affects the operating cost and long-term return on investment of the equipment.

5. Energy consumption and environmental performance of the shredder

Modern shredders usually emphasize high-efficiency and low-consumption design, which can not only reduce operating costs, but also help reduce the impact on the environment. At the same time, whether the noise level and exhaust emissions during equipment operation comply with local environmental regulations are also important conditions that need to be confirmed in advance.

The above article introduces the factors that should be considered when choosing a shredder from several aspects, including material characteristics, production capacity, output requirements, equipment durability and environmental performance. You can choose according to your own situation.

If you still have related questions, or want to buy a high-quality and durable shredder, you are welcome to contact Hengju Machinery. Hengju Machinery, as a large-scale machinery manufacturer with more than 30 years of production experience, is the top shredder manufacturer.

If you have any questions about shredders, Hengju Machinery's professional engineers can answer them for you. Please feel free to contact Hengju Machinery at any time.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/company-news/what-factors-should-be-considered-when-choosing-a-shredder.html