What kind of materials can be processed in a pyrolysis furnace?

The pyrolysis process of a pyrolysis furnace heats the raw materials to a high temperature and decomposes liquid, gas and solid by-products, which is energy-saving and environmentally friendly. When choosing materials to be processed by a pyrolysis furnace, it is necessary to consider the composition of the material, the pyrolysis characteristics and the purpose of the final product.

1. Organic waste

Pyrolysis furnaces are often used to treat organic waste such as agricultural waste, forestry waste and food industry waste. Agricultural waste such as straw and corn stalks are rich in carbon, hydrogen and oxygen, and are converted into biochar, liquid fuel and gas after pyrolysis. Forestry waste such as sawdust and branches can produce biochar after pyrolysis, which can be used for soil improvement or further converted into energy. Food industry waste such as peels and vegetable residues can reduce waste and convert it into useful by-products after pyrolysis.

2. Plastic waste

Plastic waste, such as polyethylene, polypropylene, polyvinyl chloride, etc., are common materials in pyrolysis furnaces. These plastics can be converted into liquid fuels, gases and a small amount of solid charcoal, which are particularly suitable for energy recovery.

3. Rubber waste

Waste tires and other rubber products can be converted into valuable byproducts, including rubber oil, carbon black and syngas, through pyrolysis. Pyrolysis of rubber waste can reduce waste accumulation and recover useful energy. Rubber oil can be used as fuel, carbon black can be used to make rubber products such as tires, and syngas can be used for power generation or as a chemical raw material.

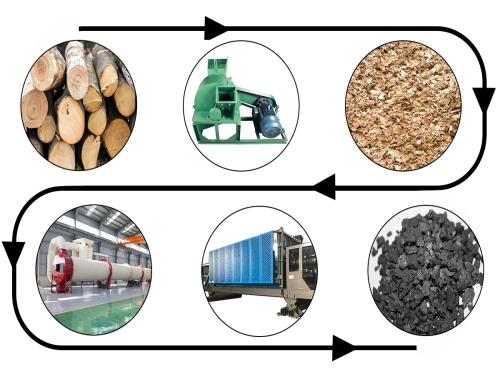

4. Wood and its byproducts

Wood and wood byproducts such as sawdust and bark are commonly used raw materials for pyrolysis furnaces. During pyrolysis, wood can be converted into biochar, syngas and wood oil. Biochar can improve soil quality, while wood oil and syngas can be used as energy or further converted into chemicals.

5. Waste electronic products

Plastic and metal parts in waste electronic products are also suitable for treatment by pyrolysis technology. Pyrolysis can recover metals and precious metals in electronic waste. At the same time, the plastics in electronic waste are converted into liquid fuels and gases through pyrolysis, which helps to reduce the harm of electronic waste to the environment and recover valuable resources.

As an efficient waste conversion equipment, pyrolysis furnace can process various types of organic materials, including agricultural waste, plastic, rubber, wood and its by-products, waste electronic products, textile waste, etc.

When choosing a pyrolysis furnace, you should choose one made by a large enterprise. For example, Hengju Machinery has its own factory and design team. The pyrolysis furnaces it produces are sold all over the world, helping different customers solve different processing needs. Regardless of the type of processing raw materials, Hengju Machinery's engineers can customize a pyrolysis furnace for you. If you need it, please feel free to consult Hengju Machinery.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/what-kind-of-materials-can-be-processed-in-a-pyrolysis-furnace.html