Maximum Processing Capacity of Metal Shredders: Influencing Factors, Types and Selection Guide

Metal shredders play a key role in the field of scrap metal recycling and processing. Their processing capacity directly affects the production efficiency and applicable scale of the equipment. The following are several factors that mainly affect the processing capacity of metal shredders:

Main factors affecting the processing capacity of metal shredders

Equipment power

The processing capacity of metal shredders is usually affected by the power of the motor. The higher the power, the more metal the shredder can process. High-power motors can provide greater torque, allowing the blades to run at high speeds, quickly cutting and crushing metal, thereby improving processing capacity.

Number and material of blades

Blades are an important part of metal shredders. Their number, material, sharpness, etc. will directly affect the processing efficiency. High-quality and wear-resistant blades can extend the service life of the equipment and greatly increase the processing capacity.

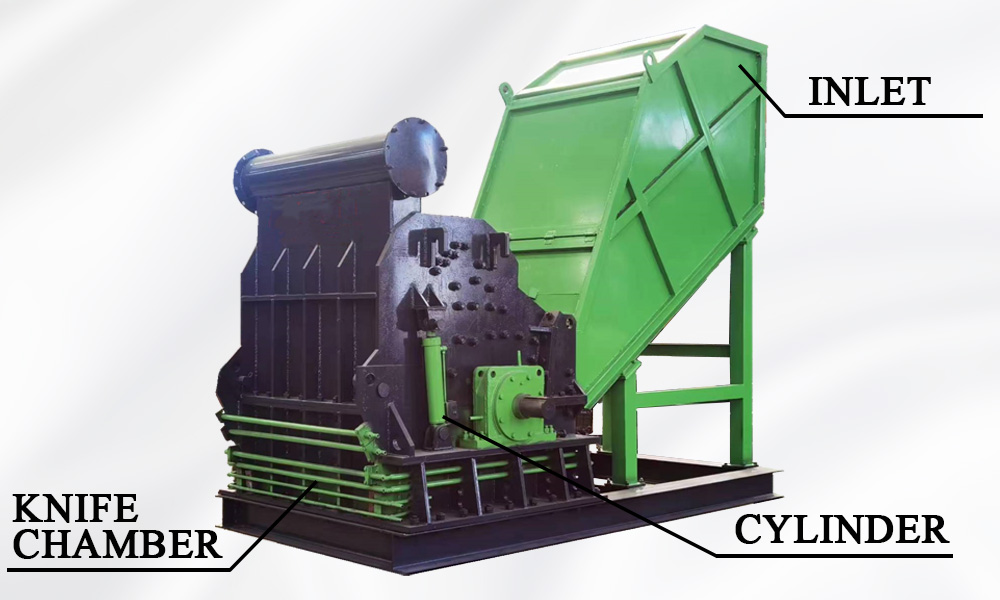

Feed port size and hopper design

The feed port size of the shredder limits the volume of metal blocks that can be fed in at a time. For large metal objects, the wider the feed port, the greater the processing capacity of the equipment. In addition, the structural design of the hopper will also affect the flowability of the metal and the throughput of the equipment.

Metal material and density

Different metals have different densities, so even shredders with the same processing capacity will have different specific shredding speeds when facing different materials such as steel, aluminum or copper. For example, aluminum has a lower density than steel, so the amount of aluminum scrap shredded per unit time is usually greater.

Capacity range of different types of metal shredders

Small metal shredders

Suitable for home, laboratory or small operation scenarios, the maximum processing capacity is generally 300-500 kg/hour. These devices are suitable for processing smaller scrap metals, such as aluminum cans, iron wire, etc.

Medium metal shredders

This type of equipment is suitable for small and medium-sized recycling plants, with a processing capacity range of 1-3 tons/hour, suitable for processing larger volumes of metal scrap such as frames and scrap household appliances. For example, the medium-sized metal shredders provided by Henan Hengju Machinery Co., Ltd. are widely recognized in the industry for their high efficiency and reliability.

Large metal shredders

Large metal shredders have a processing capacity ranging from 5-20 tons/hour, suitable for large-scale metal recycling plants at the industrial level, and are often used to process scrap cars, metal components and large machinery and equipment. Henan Hengju Machinery Co., Ltd.'s large metal shredders meet the needs of large recycling plants with advanced production technology and excellent after-sales service.

Super-large metal shredders

Specially used in super-large metal recycling plants, these shredders can even handle more than 50 tons per hour, suitable for handling super-large volumes of metal waste. These devices are large and usually specially customized.

How to choose the right metal shredder capacity according to your needs?

Determine the type of metal and average volume

Different types of metal have different densities and hardnesses. When choosing a shredder, you need to consider the type and average volume of metal to be processed. For the recycling of a variety of different metals, it is more appropriate to choose a shredder with high adaptability and a large feed port.

Weigh the size of the plant and capacity requirements

Evaluate the total amount of metal waste that the company needs to handle on a daily basis and choose a shredder that matches it. For example, small operations recommend choosing equipment with a processing capacity of less than 1 ton, while large recycling plants need to choose equipment with more than 5 tons to ensure efficient production.

Consider the energy consumption and maintenance costs of the equipment

The larger the processing capacity of the metal shredder, the higher its energy consumption. Therefore, when choosing equipment, enterprises need to take into account both processing capacity and power consumption, and avoid choosing equipment with excess processing capacity to reduce unnecessary energy waste and maintenance costs.

Summary

The processing capacity of metal shredders ranges from 300 kg/hour to 50 tons/hour. Metal shredders of different sizes and types are suitable for various recycling scenarios. Enterprises should choose suitable metal shredders based on factors such as the type of metal scrap, the amount of recycling, and the cost budget to ensure that the equipment processing capacity matches the actual needs.

Henan Hengju Machinery Co., Ltd. is a modern technology company integrating production, research and development, and sales. It strictly adheres to the principle of quality first and customer first, and provides warm and thoughtful pre-sales services such as market analysis, investment planning, on-site design, customized products, and after-sales service. Their metal shredders are widely recognized in the industry for their high quality, advanced technology, and excellent after-sales service.

Through appropriate selection, not only can production efficiency be improved, but also costs can be saved in the long run and resource reuse rate can be improved. Therefore, choosing a reliable supplier, such as Henan Hengju Machinery Co., Ltd., is essential to ensure the performance and reliability of the equipment.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/maximum-processing-capacity-of-metal-shredders-influencing-factors-types-and-selection-guide.html