How to choose the right charcoal machine?

A charcoal machine is a device that converts biomass raw materials such as wood and crop waste into charcoal. With the increasing awareness of environmental protection and the widespread application of biomass energy, the demand for charcoal machines is increasing. Choosing the right charcoal machine can not only improve production efficiency, but also reduce production costs, so there are many factors to consider when purchasing.

1. Understand production needs and output requirements

Before choosing a charcoal machine, you first need to clarify your production needs and target output. The model and configuration of the charcoal machine are usually closely related to the production capacity. Different models of charcoal machines have significant differences in the amount of raw materials they can process per hour. Some small charcoal machines can process hundreds of kilograms of raw materials per hour, while large charcoal machines can process several tons of raw materials.

2. Pyrolysis technology of equipment

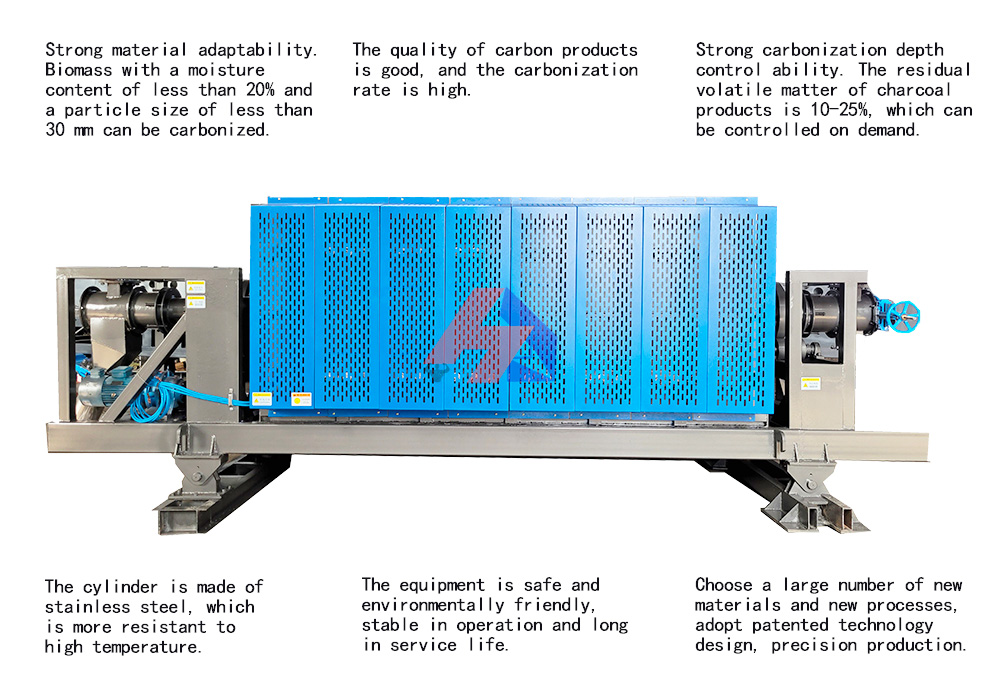

The core technology of the charcoal machine is the pyrolysis process. Choosing equipment with efficient pyrolysis technology can increase charcoal production and reduce energy consumption. Here we recommend the continuous charcoal machine produced by Hengju Machinery. The continuous charcoal machine is more suitable for large-scale production, can continuously input raw materials and produce charcoal, and is more suitable for long-term production, with high production efficiency and low labor cost. cost.

3. Energy consumption and environmental performance

In the charcoal production process, energy consumption and environmental protection issues cannot be ignored. The charcoal machines produced by Hengju Machinery use advanced energy recovery technology to reduce energy consumption, while also reducing the emission of waste gas, waste water and other pollutants, ensuring that your production complies with local environmental protection regulations.

4. Consider equipment durability and maintenance services

Charcoal machines usually need to operate continuously for a long time. The charcoal machines produced by Hengju Machinery use high-quality materials and exquisite craftsmanship, which greatly extends the service life of the charcoal machine and reduces the need for frequent maintenance. Hengju Machinery provides professional after-sales service and technical support to ensure that problems with the equipment during the production process are resolved promptly and to avoid production stagnation due to malfunctions.

Choosing a suitable charcoal machine requires comprehensive consideration of factors such as production needs, raw material characteristics, pyrolysis technology, energy efficiency, equipment durability and after-sales service. Taken together, the charcoal machine produced by Hengju Machinery has good adaptability, is equipped with professional environmental protection recycling technology, and has perfect after-sales service. It can be said that it is the best choice for charcoal machine.

If you have any questions about the charcoal machine, you are welcome to consult Hengju Machinery, and our professional engineers will provide you with professional answers.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/how-to-choose-the-right-charcoal-machine.html