How energy efficient is a continuous biochar machine compared to traditional models?

Compared with traditional biochar machines, continuous biochar machines have more significant advantages in the recovery and utilization of heat energy, production technology, automation and environmental protection.

1. Advantages of continuous production model

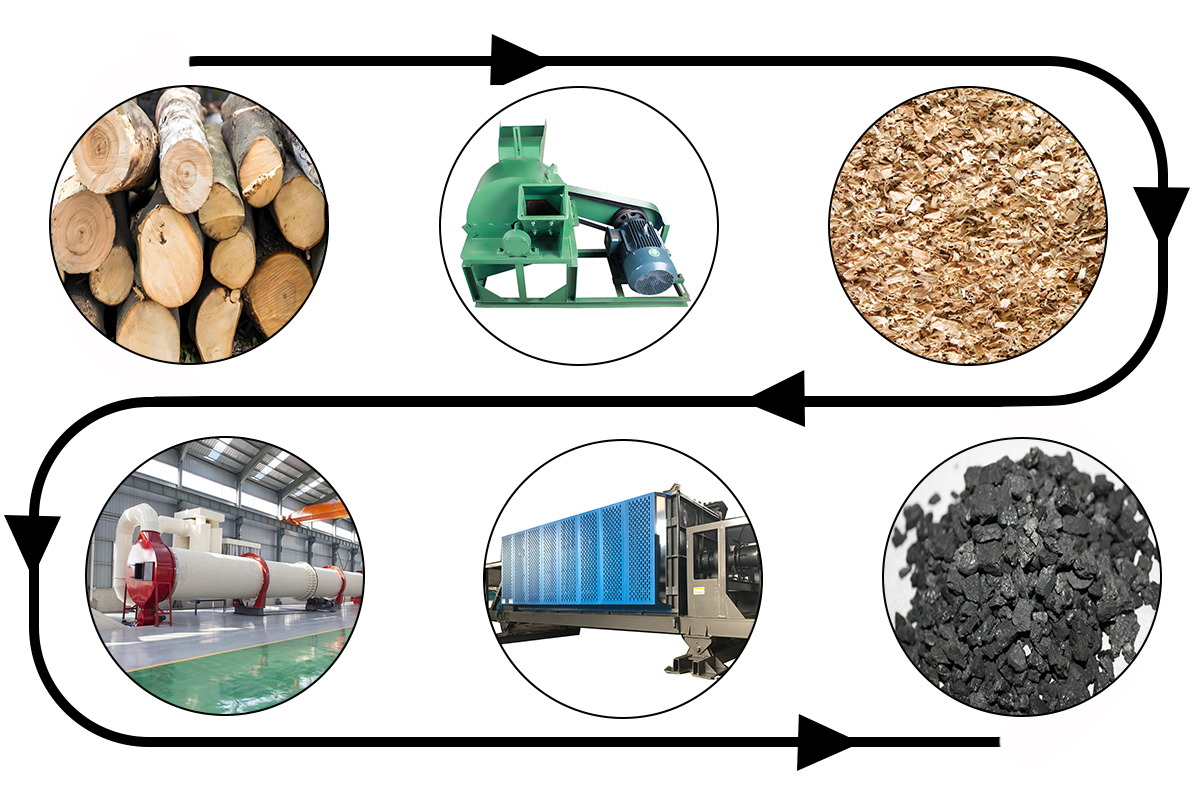

Traditional biochar machines are usually intermittent operations, that is, each batch of raw materials needs to be processed independently, and the production cycle is limited by steps such as cooling, heating, and cleaning of the equipment. This mode of operation results in significant energy waste in the equipment during each production cycle. In contrast, the continuous biochar machine adopts a continuous feeding and continuous production mode. This design ensures that the temperature inside the system remains stable without repeated heating and cooling, thereby reducing heat energy loss.

2. Heat recovery and reuse

Another key energy efficiency improvement of continuous biochar machines is the application of heat energy recovery technology. Modern continuous models often have integrated heat recovery systems, which allow the waste heat generated during the production process to be reused for heating raw materials. This reuse process reduces reliance on external energy sources, further reducing the overall energy consumption of the device.

3. Production process optimization

The continuous biochar machine is designed with a more sophisticated temperature control and airflow management system in mind. By optimizing the temperature and reaction time in the pyrolysis reaction, the continuous biochar machine ensures higher utilization of heat energy. The fully enclosed design of the continuous model also reduces heat loss and the impact of external temperature changes, making it more competitive in terms of energy efficiency.

4. High degree of automation, reducing manual energy consumption

Continuous biochar machines typically feature a high degree of automation, reducing the need for manual intervention during operation. This not only reduces labor costs, but also avoids energy waste caused by manual operations. In contrast, traditional models often require more manual operation and monitoring, and are prone to waste of energy due to human errors.

5. Environmental benefits and carbon emissions

Because continuous biochar machines use energy more efficiently, their carbon emissions are also relatively low. Through heat energy recovery and reuse, the continuous model not only reduces fossil energy consumption, but also reduces greenhouse gas emissions.

Therefore, it is still recommended that you choose a continuous biochar machine with more prominent advantages in all aspects. Hengju Machinery has decades of experience in the field of continuous biochar machine manufacturing, and the equipment it produces has received unanimous praise from domestic and foreign customers.

If you have more questions about the continuous biochar machine, Dongdu welcomes you to contact Hengju Machinery and we will be very happy to answer your questions.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/how-energy-efficient-is-a-continuous-biochar-machine-compared-to-traditional-models.html