How to make biochar how to make biomass activated carbon in bulk

Biochar production methods vary widely, including traditional pile burning, kiln burning, and furnace burning, as well as more advanced physical, chemical, and combined physical-chemical methods. This article details these methods, with a particular focus on batch production of activated biochar.

Traditional Production Methods

Pile Burning Method

1. Stack carbonization materials (such as agricultural and forestry waste) on wooden supports, cover with small branches or straw, and seal with clay, creating smoke outlets or installing a smoke pipe.

2. Ignite for burning, though this method is relatively primitive with difficult control over efficiency and product quality.

Kiln Burning Method

1. Cover wood with soil or place it in ground pits for carbonization.

2. This method is slow with poor quality control, often resulting in reduced carbon yield or incompletely carbonized products.

Furnace Burning Method

1. Utilize equipment such as fuel-efficient carbon furnaces or removable carbon furnaces for carbonization.

2. Rotary kiln burning offers a compact structure, easy operation, high carbon yield, and good quality, with less labor intensity and seasonal impact. The Continuous Carbonization Furnace is currently the most advanced and highest-yield method for biochar production.

Batch Production of Activated Biochar

Batch production of activated biochar primarily employs physical, chemical, or combined physical-chemical methods.

Physical Method

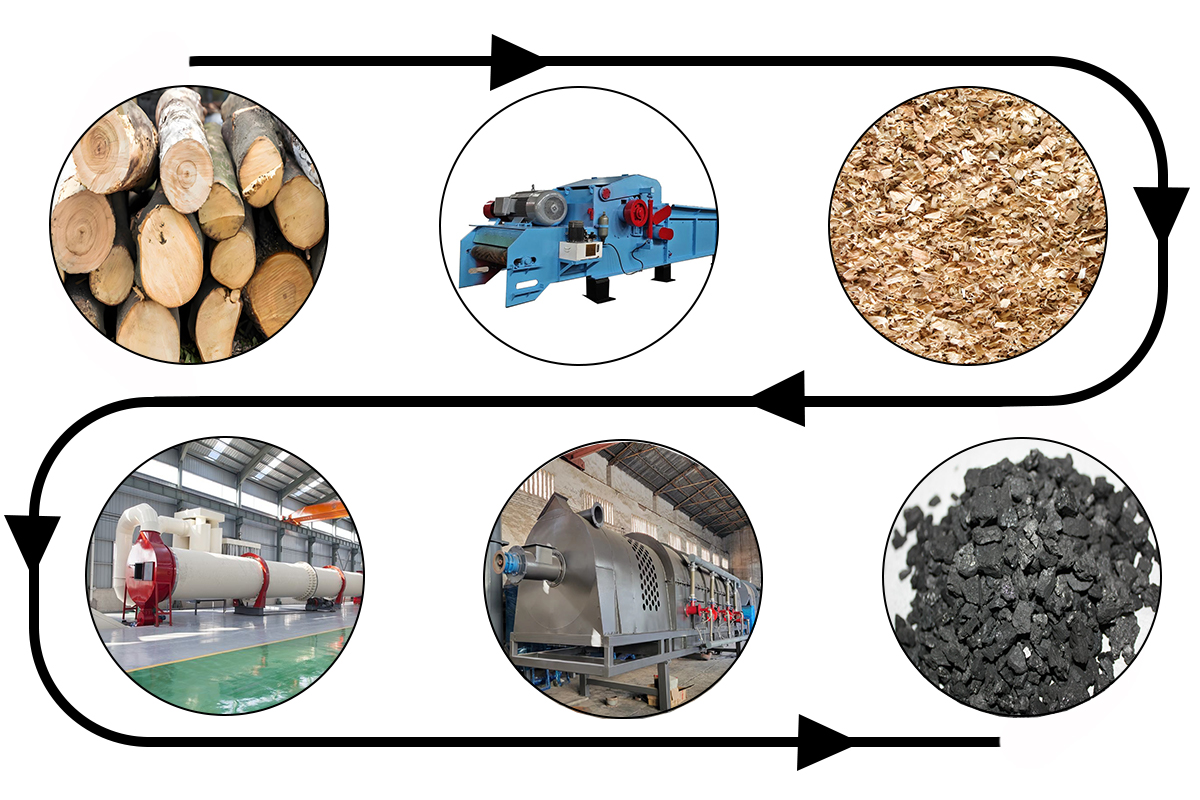

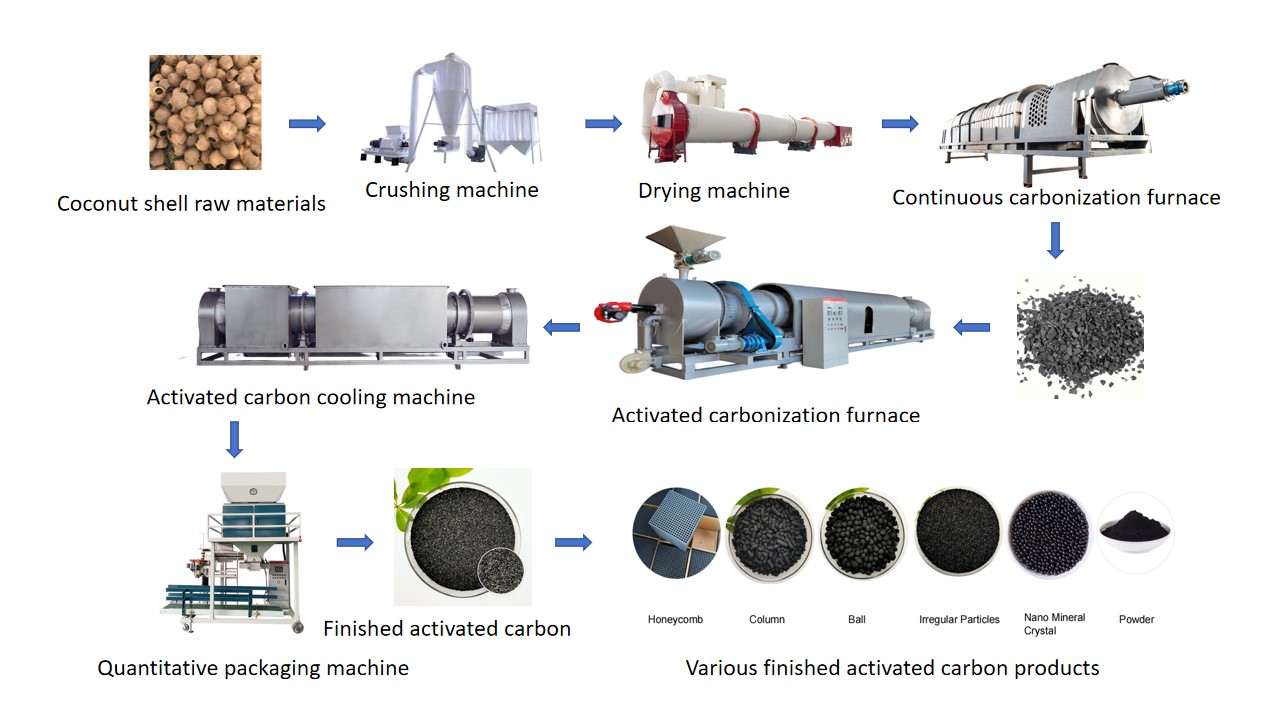

1. Raw material processing: Pretreat high-quality hardwood, nutshells, coconut shells, or coal through crushing and drying to reduce moisture content and improve carbonization efficiency.

2. Carbonization: Heat organic carbon-containing materials to decompose, allowing non-carbon elements to escape as volatile gases, producing a carbon-rich solid pyrolysis product.

3. Activation: Treat the carbonized product with oxidizing gases such as carbon dioxide, steam, or air to develop a microporous structure, enhancing adsorption performance.

Chemical Method

1. Chemical modification: Soak raw materials in chemical reagents (e.g., H2SO4, ZnCl2, H3PO4, KOH) for modification treatment.

2. Carbonization and activation: Perform carbonization and activation at specific temperatures to create a microporous structure within the activated carbon, increasing surface area and enhancing adsorption capacity.

Company Information

Hengju Machinery specializes in biochar production equipment, offering high-quality rotary kilns and equipment for physical and chemical methods to achieve batch production of activated biochar. Our equipment features high efficiency, durability, and ease of operation to meet your diverse needs. We also provide technical support and after-sales service to address any issues in your biochar production process.

Important Considerations

Strictly control parameters such as temperature and time during production to ensure product quality. Selecting appropriate raw materials and equipment is crucial for improving production efficiency and product quality. For batch production, consider the stability of raw material supply and the continuity of the production process.

In conclusion, batch production of activated biochar requires combining modern physical and chemical technologies, involving meticulous raw material processing, scientific carbonization and activation processes, and rigorous post-processing steps.

For more information about biochar production equipment or customized solutions, please contact Henan Hengju Machinery Equipment Co., Ltd. We are committed to providing you with the most advanced biochar production technology and equipment, helping you succeed in this rapidly developing industry while contributing to environmental protection and sustainable development.

Copyright: Copyright belongs to Hengju Machinery! Reprint please indicate the source: https://www.hengjumachinery.com/industry-news/continuous-carbonization-furnace-activated-carbon-production-line.html