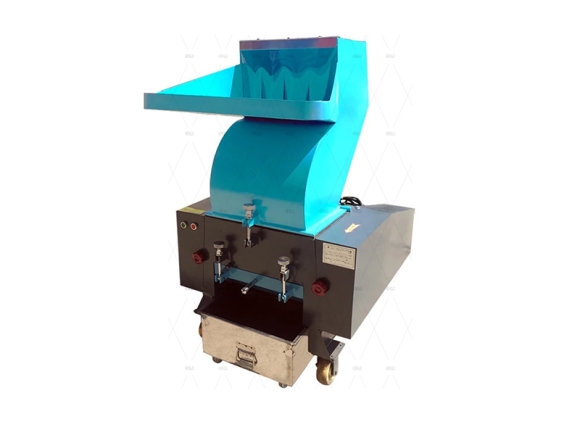

Plastic crusher, also called plastic crusher, is mainly used to crush various plastic plastics and rubber such as plastic profiles, tubes, rods, threads, films, and waste rubber products. The pellets can be directly used in extruders or injection molding, or they can be regenerated through basic granulation. The plastic crusher is also a peripheral equipment of the injection molding machine. It can crush and recycle the defective products and nozzle materials produced by the injection molding machine.

Working Principle

The plastic crusher drives the movable knife cutterhead to rotate at high speed through the motor. During the high-speed rotation of the movable knife, it forms a tendency of relative motion with the fixed knife. The gap formed between the movable knife and the fixed knife is used to create incisions for plastic crushing and shearing. The large pieces of plastic are broken, and the broken plastic is filtered and output through a screen to reduce the size of the plastic particles.

Features

1: Alloy steel blade, sharp and wear-resistant, trapezoidal design, doubles the cutting force, adjustable gap, can be polished multiple times after being blunted, and used repeatedly

2: Double-layer soundproof box to reduce noise trouble, made of thickened double-layer steel to reduce noise during crushing

3: Pure copper motor, long service life, using Yexiang or Guoyu motor, 1445/MIN rotation, strong power, low failure rate, durable, built-in overload protection and power supply protection

Scope of application

Plastic crusher is suitable for plastic containers, laundry liquid bottles, plastic quality products, water material, PE, PVC, ABS, packaging bags

Cassava tendons, medicinal materials, chemical materials, cardboard boxes, non-woven fabrics, wire and cable, etc