Production

Hengju machinery production of single axis, double axis, four axis shredding machine is mainly used for industrial waste, electronic waste, household waste, waste plastic, scrap metal and other shredding processing, so as to achieve the purpose of secondary recycling.

Production details

Shredder blade The shredder blade is forged, annealed, heat-treated, tempered and heat-preserved, and finely ground on wire cutting.

Shredder transmission The shredder body is welded with steel plates, with high precision, good contact, low noise and long service life.

Shredder motor The shredder motor adopts all-copper core motor, which reduces energy consumption and has a long service life.

working principle

Material through the feed system into the interior of the shredding box, the box bearing four groups of blades, the material through the blade tearing, extrusion, shearing and other comprehensive forces under the action of crushing, shredded into small pieces of material, when the size of the material is less than the screen hole when the material under the action of gravity and extrusion pressure from the bottom of the box screen hole discharge, Larger materials will continue to be crushed in the crushing chamber until the size is smaller than the screen hole.

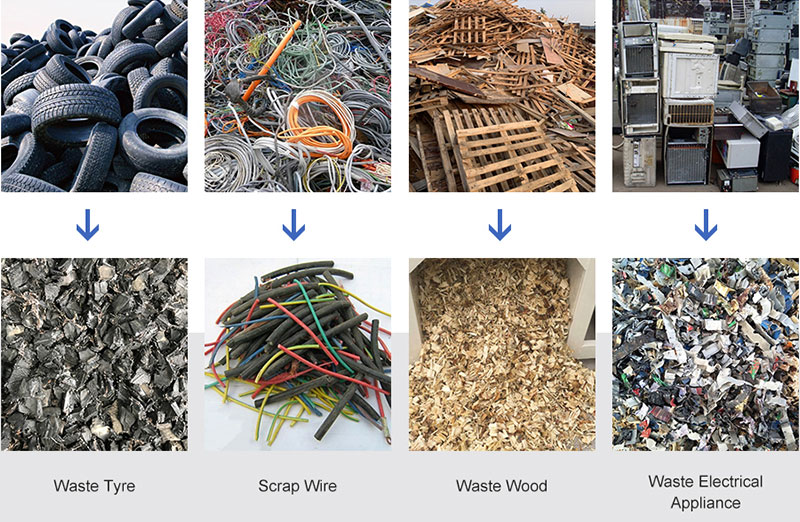

Scope of application

The shredder can shred all kinds of plastic cans, plastic drums, iron drums, packing cases, packaging drums, plastic bottles; Waste household appliances: TV, washing machine, refrigerator shell; Pipe: large pipe, pipe fittings, PE pipe; Waste formwork: wood pallet, plastic pallet, forklift pallet; Waste tires: car tires, truck tires; Scrap metal: automobile shell, aluminum alloy, scrap cast aluminum parts, engine shell, lead and steel plate with thickness below 5mm; Kitchen waste, household waste, animal carcasses, medical waste, tree roots, garden waste, etc.