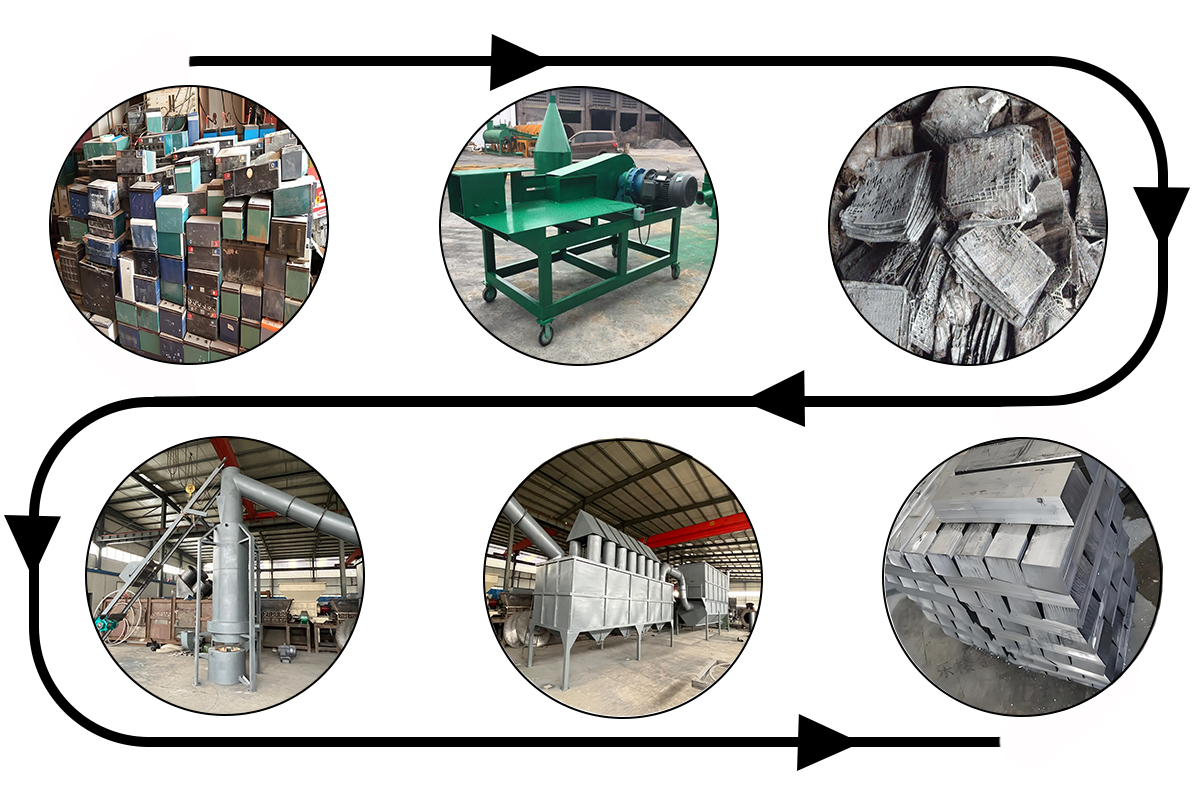

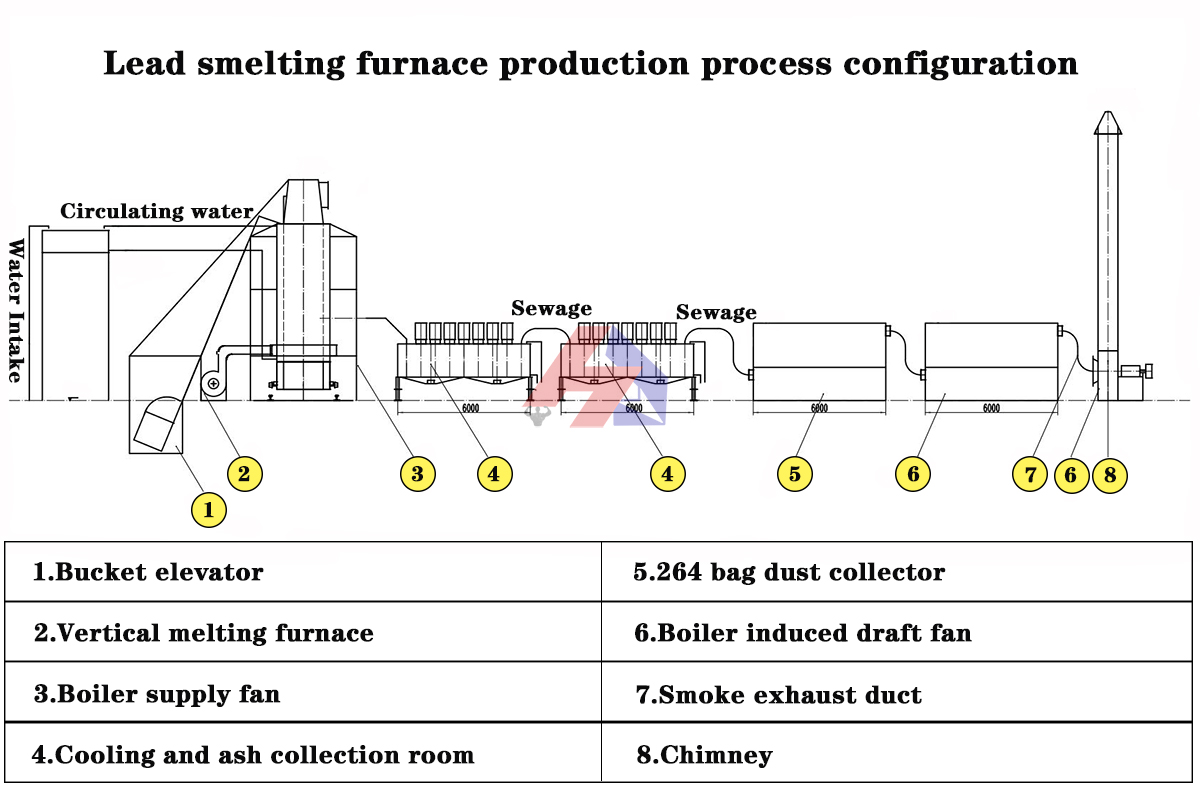

The vertical lead smelting furnace is an environmentally friendly equipment for recycling and treating hazardous waste, developed based on the principle of cupola smelting, combined with modern technology and the latest experimental results. The complete set of equipment consists of: elevator, cupola, melting chamber, circulating water cooling chamber, annular flue, bag filter, ventilation duct, etc.

Advantages of lead-acid waste battery lead smelting furnace:

1. High economic efficiency

The production line has low start-up and shutdown costs. It only takes 1 hour from starting the furnace to putting in raw materials, and the daily output can reach 30-150 tons. The smelted lead blocks have high purity and good reducibility, and can be sold at a high price.

2. High reducibility

The raw materials in the furnace are fully burned in a high-temperature and low-oxygen environment above 1200℃, and the refined lead blocks are of high purity.

3. Water circulation cooling system

The flue adopts a closed annular flue, and the high-temperature lead gas is cooled in the circulating water tank, which is better than traditional air cooling. When the lead ash accumulated in the flue reaches a certain weight, it can be automatically discharged. The dust collector combined with the annular flue fundamentally solves the disadvantage of traditional equipment that the furnace needs to be shut down for ash removal.

4. Flue gas purification

The furnace smoke is cooled by 2-4 large cooling water tanks. After ash removal, the particles in the flue gas are filtered again through high-temperature resistant bags, and then processed by professional desulfurization equipment, so that the flue gas emissions meet the environmental protection standards of various countries.

Structure of the lead smelting furnace

1. Upper box: composed of a liftable cover and an air outlet.

2. Middle box: composed of a porous plate, a filter bag device and a venturi tube.

3. Lower box: composed of an air inlet, an ash hopper and an inspection door.

4. Cooling and ash removal system: composed of a deceleration device and an ash conveying and ash removal device.

5. Purification and dust removal system: composed of multiple bag dust collectors made of wear-resistant and high-temperature resistant materials.

Working principle of lead smelting furnace:

In the process of air inlet entering the middle and lower boxes and entering the upper box through the dust bag, the dust and gas are separated due to various effects of the filter bag. The dust is adsorbed on the surface of the dust bag, and the gas passes through the dust bag and enters the upper box through the venturi tube and is discharged from the air outlet. In the process of dust-containing gas passing through the filter bag for purification, more and more dust is on the surface of the filter bag, which gradually increases the resistance of the bag and gradually reduces the amount of gas passing through the dust bag. In order to make the dust collector work normally, the resistance must be controlled within a limited range. When the resistance reaches the limited range, the pulse controller sends a command to trigger each control valve to open the pulse solenoid valve in sequence. The compressed air in the air bag is sprayed into the corresponding dust bag by the blowing pipe. The bag expands rapidly under the instantaneous reaction of the airflow, causing the dust accumulated on the surface of the filter bag to fall off and the filter bag to be regenerated. The cleared dust falls into the ash hopper and is discharged through the ash discharge system.

Based on many years of manufacturing experience, our company has continuously carried out technological innovation on this process and successfully developed a complete set of equipment for lead smelting furnace production lines with various outputs. We provide installation and technical training services to this customer, enabling them to produce qualified products. This has been well received by users for many years.