Product description

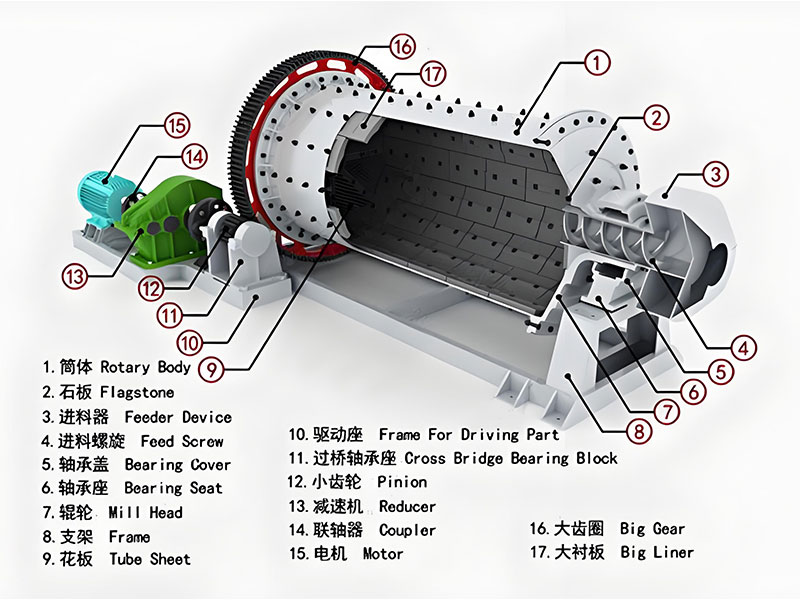

The ball mill is a grinding machine that also has a mixing effect. The body of the ball mill is cylindrical, containing a spherical grinding body and materials; the centrifugal force and friction generated when the body rotates bring the materials and the grinding body to a certain height at the same time and then fall. After constant collision and friction with each other, the materials are ground. into fine powder. Ball mills can be divided into dry and wet methods; wet operation is often equipped with a classifier, and dry operation is equipped with exhaust and separation equipment.

Application scope

It is widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal mineral processing, glass ceramics and other industries. Dry or wet grinding of various ores and other grindable materials. Ball mill is suitable for grinding various ores and other materials, and is widely used in mineral processing, building materials and chemical industries. According to different ore discharge methods, it can be divided into two types: grid type and overflow type.

Grinding media

Different grinders are used according to different materials. Grinders can be roughly divided into two categories: metal and non-metal. Metallic ones include stainless steel beads and tungsten steel beads; non-metallic ones include alumina ceramics, zirconium ceramics, pebbles and marbles, etc. For example, when grinding sulfur, phosphorus and iodine, ceramic grinders should be used for substances that interact with metals. Ceramic grinders can grind most substances, but their disadvantage is that they are more difficult to clean.

The diameter of the ground product depends on several physical factors:

1. Grinding frequency (related to grinding quantity, volume, grinding barrel speed, etc.)

2. The length of grinding time (frequency multiplied by time equals the number of times, the more times of grinding, the smaller the diameter)

3. Physical and chemical properties of the abrasive (such as ductility, brittleness, mechanical stability)

4. The geometry and material of the grinding barrel (a factor that affects frequency)