The Rotary Cooling Machine is a versatile industrial equipment designed to efficiently cool various materials, including metal dross, slag, and other industrial byproducts. Featuring a rotating drum structure, this cooling machine ensures rapid heat dissipation and uniform temperature control, making it a reliable solution for a wide range of industrial cooling needs.

Product Introduction: Rotary Cooling Machine

Product Purpose: The Rotary Cooling Machine is an efficient industrial cooling solution primarily used for cooling various high-temperature materials such as metal slag and aluminum dross. This equipment utilizes rotational principles to achieve rapid and uniform cooling processes, effectively improving production efficiency and product quality. This robust equipment utilizes innovative rotational technology to deliver rapid, uniform, and controlled cooling of high-temperature materials like metal slag, aluminum dross, and incinerated waste.

Harnessing Efficiency and Innovation:

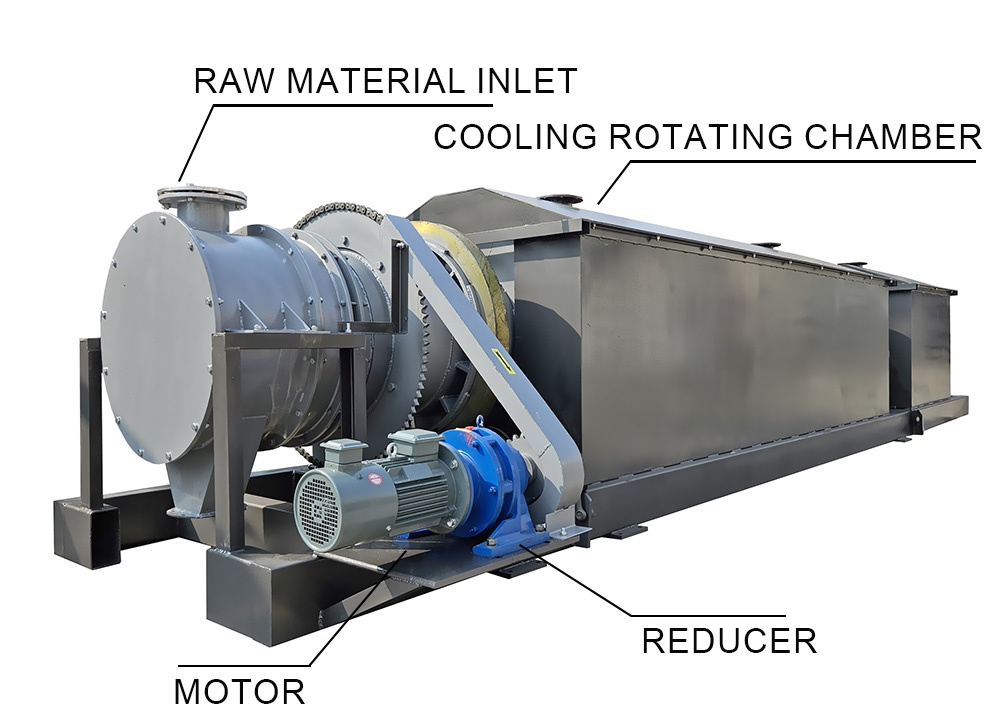

The Rotary Cooling Machine stands out for its exceptional cooling efficiency, achieved through its unique rotating drum design. This design ensures continuous and homogenous contact between the hot material and the cooling surfaces, maximizing heat transfer and minimizing cooling time. This translates into faster production cycles, increased throughput, and ultimately, enhanced profitability.

Key Advantages:

Unmatched Cooling Efficiency: The rotary design ensures even distribution and consistent contact of material with cooling surfaces, maximizing heat exchange for rapid cooling.

Reduced Energy Consumption: Advanced heat exchange technology optimizes energy use, minimizing operational costs and environmental impact.

Simplified Operation: Automated controls and user-friendly design require minimal operator intervention, reducing labor costs and training needs.

Versatility in Application: Adjustable parameters like rotation speed and cooling intensity allow for customization based on specific material properties and desired outcomes.

Enhanced Safety: Multiple safety features, including emergency stops and overload protection, ensure safe and reliable operation for both personnel and equipment.

Space Optimization: A compact footprint maximizes space utilization, allowing for easy integration into existing production lines.

Applications in Metal Smelting:

In the demanding environment of metal smelting, the Rotary Cooling Machine proves to be an invaluable asset. It efficiently cools molten slag and dross generated during metal extraction and processing. This rapid cooling:

Facilitates the recovery of valuable metals from the slag, maximizing resource utilization and minimizing waste.

Transforms molten slag into manageable, transportable solid material for further processing or disposal.

Improves the working environment by reducing heat stress and dust generation.

Applications in Environmental Recycling:

The Rotary Cooling Machine plays a critical role in environmentally sound waste management and recycling processes. In waste-to-energy plants and recycling facilities, it effectively cools incinerated bottom ash and other high-temperature residues. This efficient cooling:

Stabilizes the waste material, reducing its volume and making it safer for handling and transportation.

Prevents the release of harmful pollutants into the atmosphere, minimizing environmental impact.

Facilitates the recovery of valuable materials from the ash, contributing to a circular economy.

A Sustainable Solution:

The Rotary Cooling Machine represents a sustainable solution for industries seeking to optimize their cooling processes while minimizing their environmental footprint. By choosing this advanced technology, companies can:

Reduce their carbon emissions and energy consumption.

Promote resource recovery and waste reduction.

Enhance their environmental compliance and corporate social responsibility.

The Rotary Cooling Machine, with its robust design, proven performance, and wide range of applications, is a game-changer in industrial cooling. By adopting this innovative technology, companies in the metal smelting and environmental recycling sectors can unlock significant operational benefits, boost their bottom line, and contribute to a more sustainable future.