What is an Industrial Pyrolysis Furnace?

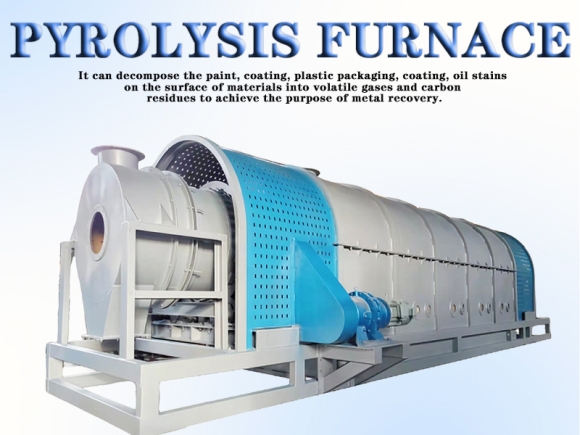

An industrial pyrolysis furnace is a state-of-the-art thermal cleaning system designed for efficient removal of organic coatings, paints, plastics, and other contaminants from metal surfaces. This advanced technology operates in a low-oxygen environment, ensuring superior control over the thermal decomposition process. By maintaining a controlled atmosphere, the furnace prevents the combustion of materials, thereby avoiding hotspots and ensuring uniform heating. This results in a more consistent and higher quality end product.

Key Features:

PLC-Controlled for Precision: Our furnaces are equipped with advanced PLC (Programmable Logic Controller) systems that allow for precise control over the temperature and duration of the thermal cleaning process. This ensures optimal performance and efficiency.

Low-Oxygen Environment: Operating in a low-oxygen environment is crucial for preventing the combustion of organic materials. This feature ensures that the material’s integrity is maintained and reduces the risk of damage.

Efficient Thermal Cleaning: The pyrolysis process effectively decomposes organic materials into volatile gases and carbon residue, leaving behind clean, reusable metal surfaces.

Environmentally Friendly: Our furnaces incorporate integrated exhaust gas purification systems that capture harmful emissions, ensuring minimal environmental impact and compliance with strict environmental regulations.

Applications Across Industries

Our industrial pyrolysis furnaces cater to a wide range of applications, making them an indispensable tool for numerous industries:

Automotive: In the automotive industry, our furnaces are used to strip paint from car parts and components. This process not only ensures a clean surface for repainting but also helps in recycling metal parts, thereby reducing waste and promoting sustainability.

Metal Recycling: The metal recycling industry benefits greatly from our pyrolysis furnaces, which are capable of processing electronic waste and reclaiming valuable metals. This not only helps in reducing e-waste but also promotes the efficient use of resources.

Beverage Industry: Efficient paint removal from aluminum cans is essential for recycling and reuse. Our furnaces provide an eco-friendly solution for this process, ensuring that the cans are free from paint and ready for further use.

Electronics: Stripping coatings from circuit boards and electrical components is a critical step in the recycling process. Our furnaces ensure that these components are clean and free from contaminants, making them suitable for reuse or further processing.

General Manufacturing: In general manufacturing, cleaning oil-contaminated metal parts is a common requirement. Our furnaces effectively remove oil and other contaminants, ensuring that the parts are clean and ready for further use or processing.

Uses of pyrolytic paint removal furnace equipment:

1. Painted workpieces (for example: waste cans, bottle caps...), remove the surface paint coating.

2. Coated workpieces, remove the surface coating.

3. Plastic coated and sprayed workpieces (e.g. electrical switches...), remove the surface plastic coating.

4. Waste circuit boards, wires, capacitors; remove PVC, polyurethane and other wrapping layers.

5. Grease, oil and dirt impregnated workpieces (e.g. aluminum chips, copper chips...), remove the surface covering oil layer and oil film.

6. Removal of powder coating layer on the surface of anti-corrosion and acid-alkali resistant workpieces.

Application industries of thermal depainting furnaces:

1. Aluminum plants, steel plants, copper plants and other metal smelting industries, recycling waste raw materials to remove impurities, reduce the impurity content of materials entering the furnace, improve the smelting level, and reduce smelting energy consumption.

2. Coating plants, repair workpieces, recycling and reprocessing.

3. Scrap metal material recycling and reuse enterprises.

Types of Pyrolysis Furnaces1. Aluminum Can Paint Stripping FurnaceOur aluminum can paint stripping furnace is designed to provide an eco-friendly solution for removing paint from aluminum cans. The furnace operates in a low-oxygen environment, ensuring that the paint is decomposed efficiently without generating wastewater. Additionally, the integrated exhaust gas purification system ensures that the process is environmentally friendly and compliant with regulations.

2. E-Waste Pyrolysis FurnaceThe e-waste pyrolysis furnace is specifically designed for processing electronic waste. By subjecting the waste to high temperatures in a controlled environment, the furnace effectively decomposes organic materials such as plastics and rubber. This allows for the efficient separation of metals from non-metallic components, facilitating the recycling and reuse of valuable materials.

Our continuous production furnace is ideal for high-volume processing. Designed for large-scale operations, this furnace provides continuous, efficient thermal cleaning for paint stripping, deplasticizing, and degreasing metal parts. The furnace’s robust construction and advanced control systems ensure reliable performance and minimal downtime.

The lithium battery recycling furnace is designed to process waste lithium batteries efficiently. By operating at specific temperatures and atmospheric conditions, the furnace decomposes organic materials such as the electrolyte and separator, allowing for the recovery of aluminum, copper, and electrode materials. This process not only promotes the recycling of valuable metals but also ensures the safe disposal of hazardous materials.

How It Works

The industrial pyrolysis furnace operates on a simple yet effective principle:

Preparation: Materials are loaded into the furnace chamber, ensuring that they are placed in a low-oxygen environment to prevent combustion.

Heating: The furnace heats to a specific temperature, which is carefully controlled and maintained for a predetermined duration. The advanced PLC system ensures precise temperature control throughout the process.

Decomposition: Organic materials such as paints, plastics, and oils undergo thermal decomposition, breaking down into volatile gases and carbon residue. This process effectively removes contaminants from the metal surfaces.

Separation: The decomposed materials separate from the metal surfaces, leaving behind clean, reusable metal. The volatile gases are captured and purified by the exhaust gas purification system, ensuring minimal environmental impact.

Result: The clean metal is ready for further use or recycling, providing a sustainable and efficient solution for material processing.

High Efficiency: Our furnaces are designed to deliver faster and more thorough cleaning compared to traditional burn-off ovens. This ensures that your materials are processed quickly and effectively, reducing downtime and increasing productivity.

Quality Preservation: The controlled heating environment prevents damage to materials, ensuring that there are no internal cracks or other defects. This helps maintain the integrity and quality of the materials being processed.

Versatility: Our furnaces are suitable for a wide range of materials and contaminants, providing a versatile cleaning solution for various industries. Whether you need to remove paint, plastics, oils, or other contaminants, our furnaces can handle it all.

Environmental Compliance: Our furnaces are designed to meet strict environmental regulations, ensuring minimal emissions and a reduced environmental footprint. The integrated exhaust gas purification system captures and purifies harmful emissions, making our furnaces an eco-friendly choice.

Cost-Effective: By reducing labor costs and increasing material recovery rates, our furnaces offer an excellent return on investment. The efficient cleaning process ensures that you get the most out of your materials, reducing waste and maximizing profits.

Advanced Control Systems: Equipped with PLC controls, our furnaces offer precise operation and monitoring. This ensures that the cleaning process is optimized for maximum efficiency and effectiveness.

Durability: Our furnaces are built to last, with robust construction and high-quality materials. This ensures long-term reliability and minimal maintenance requirements, providing you with a dependable solution for your material processing needs.

Why Choose Henan Hengju Machinery Equipment Co., Ltd.?

Expertise and Experience: With years of experience in the industry, Henan Hengju Machinery Equipment Co., Ltd. provides expert solutions tailored to your specific needs. Our knowledgeable team is dedicated to delivering high-quality products and exceptional customer service.

Customization: We understand that different industries have unique requirements. Our products can be customized to meet your specific needs, ensuring that you get the best solution for your application.

High-Quality Standards: We adhere to strict quality control measures to ensure that our products meet the highest standards of performance and safety. Our commitment to quality ensures that you get a reliable and efficient solution for your material processing needs.

Comprehensive Support: We offer expert support and maintenance services to ensure the longevity and efficiency of our furnaces. Our dedicated team is always available to assist you with any questions or concerns you may have.

Ready to revolutionize your thermal cleaning process? Contact Henan Hengju Machinery Equipment Co., Ltd. today for a customized quote and discover how our industrial pyrolysis furnace can enhance your operations.