What's the Working Process of Copper Wire Recycling Machine?

This video shows us the working process of copper wire recycling machine. Through crushing, air separating and electrostatic separating, copper and plastic can be separated from scrap wires and cables.

Working process of copper wire machine:

The copper wire first enters the shredder for preliminary processing, and then the magnetic separator selects the iron in it. Then it enters the crusher to be processed into small particles. The magnetic separator prevents iron metal from entering the crusher and causing wear on the crusher blades. The raw materials coming out of the crusher have become small particles. At this time, the copper and plastic have been separated, but are still mixed together. The next step is that the raw materials will enter the airflow separator, which will be sorted according to the weight of copper and plastic, and the sorting rate can reach more than 98%. If a higher sorting rate is required, an electrostatic separator can be installed. The electrostatic separator can select a part of the fine copper in the plastic according to the conductivity of copper and plastic, and increase the sorting rate to more than 99.5%.

Main functions

Process Waste Copper Wires: The machine is primarily used for processing waste copper wires, aluminum wires, and other types of electrical wires.

Recycle Copper and Plastic: It effectively separates and recycles the copper and plastic components from the waste cables, making it a profitable and sustainable solution.

Complete Set of Equipment: The Copper Wire Granulator Machine is a complete set of equipment that includes all necessary components for processing used copper cables.

Scope of application

Used Copper Cables: Ideal for recycling used copper cables from various sources.

Automotive Wires: Can process automotive wires and other types of electrical wires.

Tanglesome Wires: Capable of handling tangled and complex wire structures.

Environmental protection features

Environmental Protection: This machine is an environmental protection recycling solution that helps reduce waste and promote sustainable practices.

Economic benefits

Profitable Recycling: By recycling copper and plastic, this machine offers a profitable way to manage waste materials.

Benefits

Environmental Protection: This machine is an environmental protection recycling solution that helps reduce waste and promote sustainable practices.

Profitable Recycling: By recycling copper and plastic, this machine offers a profitable way to manage waste materials.

Efficient Processing: The machine is designed for efficient processing, reducing labor costs and increasing productivity.

What Raw Materials Can be Recycled by Copper Wire Recycling Machine?

What types cable wires could be recycled?

Copper wire recycling machine recycles scrap cable wires through crushing and separation process, so it has no limit for the input cable wire size or types. Any building wires and cables, industrial cables, low voltage cables, flexible cords, fixture wires or special purpose wire and cable, like battery lead wire, boat wire, bus drop cable, electric vehicle cable, festoon cable, distributed generation cable, etc, all could be recycled through copper wire recycling machine.

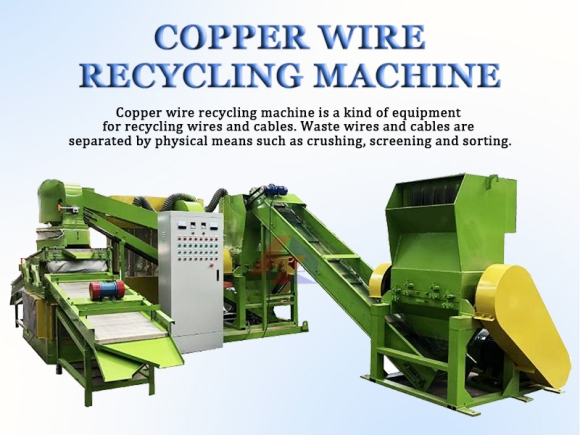

The Copper Wire Recycling Machine, also known as the Scrap Copper Wire Recycling Machine, is a comprehensive solution for processing used copper cables, automotive wires, and other tangled wires. This environmental protection recycling machine is designed to efficiently recycle copper and plastic from waste cable wires.