The core advantages of Flat Die Biomass Pellet Machine lie in its high productivity, adaptability to diverse raw materials, high-quality product output, energy-saving and environmentally friendly design, intelligent operating system and significant economic benefits. It adopts advanced flat-die pressing technology, which can efficiently process a variety of biomass raw materials and produce standardized pellet fuel with high density and high calorific value. At the same time, the equipment's intelligent operating system, energy-saving and environmentally friendly design and high-quality product output ensure the stability, reliability and environmental protection of the production process. The most important thing is that it can convert low-value waste into high-value fuel, creating new profit points. The investment return period is short, and the cost can usually be recovered within 1-2 years.

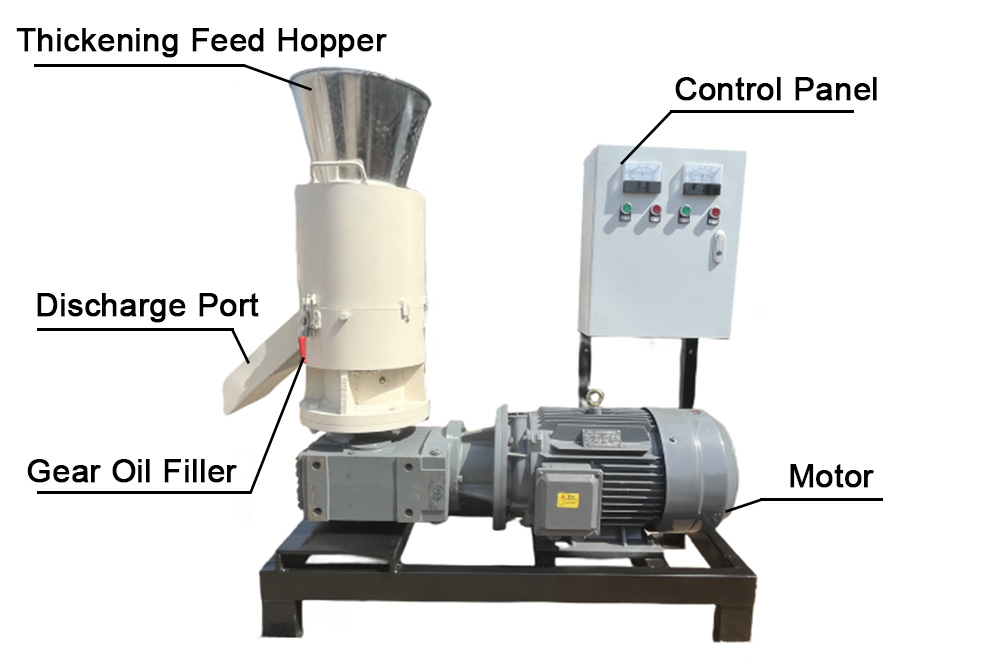

Product description

Solid wastes such as corn stalks, wheat straw, rice straw, peanut shells, corn cobs, cotton stalks, soybean stalks, chaff, weeds, branches, leaves, sawdust, bark and other agricultural crops are used as raw materials, and are crushed, pressurized and Dense and shaped into small rod-shaped solid particle fuel.

Work process

1: Crush agricultural and forestry processing waste such as wood chips, straw, rice husks, bark and other biomass into materials with smaller particle sizes for subsequent processing.

2: After crushing, the raw materials are fed into the granulator and compressed to turn them into compact granules. This step requires controlling parameters such as temperature and pressure to ensure the quality and molding rate of the particles.

3: After compression treatment, the raw material enters the molding machine and is turned into particles of consistent size and regular shape through the action of the mold. This step requires the selection of different molds based on different raw materials and particle sizes to ensure the quality and molding rate of the particles.

Purchase Recommendations

Based on your production needs, site conditions and budget, Hengju Machinery can recommend the most suitable model for you. Please contact Hengju's sales team for personalized solutions and quotes.

Return on Investment

Many customers have reported that after using our Flat Die Feed Pellet Machine, feed costs have been reduced by 20-30% and production efficiency has been increased by more than 40%. The specific ROI may vary depending on the usage, and we can provide you with a detailed cost-benefit analysis.

Why Choose Us

20 Years of Professional Manufacturing Experience: Hengju Machinery has 20 years of professional manufacturing experience, mature technology and reliable products.

Strict quality control system: Strict quality control system to ensure the quality of each equipment.

Perfect after-sales service network: Perfect after-sales service network to provide comprehensive after-sales support.

Continuous technological innovation: Continuous technological innovation to continuously improve product performance and service quality.

Many successful cases and word of mouth: Many successful cases and user word of mouth prove our products and services.