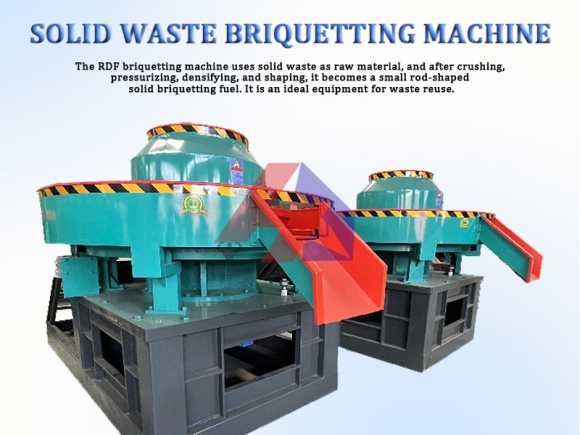

The RDF briquetting machine uses solid waste as raw material, and after crushing, pressurizing, densifying, and shaping, it becomes a small rod-shaped solid briquetting fuel. It is an ideal equipment for waste reuse.

Working principle

The working principle of the solid waste briquetting machine is to put the solid waste into the hopper, drive the hydraulic system through the motor to generate high pressure, and press the waste under the action of the mold. Under the action of high pressure, the waste forms solid briquettes and is discharged through the discharge port.

Feature

1. The synchronous symmetrical mechanical design of double pressure rollers not only increases productivity but also enhances stability and reduces the equipment failure rate.

2. Improve the design of the mold, synchronize the pressure wheel wear, facilitate gap adjustment, effectively extend the service life of core components, meet the needs of long-term uninterrupted production, and greatly reduce maintenance costs.

3. Simple structure, convenient for maintenance and repair; the maintenance bracket is centrally designed to facilitate the maintenance of the whole machine.

4. Increase the effective counterweight to make the operation more stable, safe, anti-stuffing and noise-free.

5. The feeding system has an anti-stuffing machine active control device that can adjust the feeding according to current changes, thereby preventing the machine from becoming stuffy and making production more worry-free.

6. The core components of this machine have been comprehensively improved to increase the load-bearing strength, especially for the production of raw materials with high hard lignin such as cottonwood and branches, which is more efficient.

7. This machine is specially equipped with electric heating and automatic temperature adjustment devices, which is especially suitable for normal production needs in cold areas and winter, saving more than 40% of power consumption.

8. The core components are forged and formed using special materials with high wear resistance, high strength and high toughness. After special treatment, they have a longer service life and lower maintenance costs. They can be reused after repair without replacement.

Scope of application

The solid waste briquetting machine is suitable for industrial waste, organic waste, papermaking waste, washing plant waste, textile waste, leather waste, rag waste, water plant sludge, industrial sludge and other raw materials