"Before switching to Hengju Machinery, our traditional methods were inefficient and time-consuming with dismal yields. The charcoal furnace revolutionized our production - tripling output while maintaining premium quality. Its automated operation significantly reduced labor costs. This investment paid for itself within months!"

Batch Carbonization Furnace, Horizontal Carbonization Furnace

Batch Carbonization Furnace,Industrial-Grade Horizontal Carbonization Furnace Certified by CE & ISO 9001 | 300+ Global Installations Increase efficiency, reduce costs, and improve product quality with our advanced charcoal manufacturing equipment

Reliable & Efficient

Charcoal Production Solutions

Trusted by 500+ Manufacturers Worldwide

Are you looking for a reliable and efficient way to produce high-quality charcoal? Our advanced wood charcoal machine is engineered to exceed your production targets .

🏭 Industry Expertise

15+ years refining manufacturing technology for optimal performance

📈 Scalable Solutions

Modular systems from 500kg to 5ton/hour production capacity

| ⚡ Production Revolution | ||

|---|---|---|

|

⏱️

|

2X Faster Production

↑ 150% Output

|

Automated continuous operation enables 24/7 production cycles with 90% less manual intervention. Intelligent sensors maintain optimal pyrolysis conditions (±5°C) for maximum throughput. |

|

💰

|

Smart Cost Control

↓ 40% OPEX

|

Closed-loop energy recovery system reduces fuel consumption by 65%. Predictive maintenance algorithms cut downtime costs by 80% compared to conventional systems. |

|

🌟

|

Premium Quality

ISO 17225 Certified

|

Precision temperature control ensures 99% carbon purity. Automated sorting system guarantees uniform charcoal size (Ø25±2mm) meeting export-grade specifications. |

Performance Comparison

Traditional Methods vs Our Modern Machines

| Metric | Traditional Methods | Our Machines | Improvement |

|---|---|---|---|

| Production Capacity | 200 kg/hour | 500 kg/hour | ↑ 150% |

| Energy Consumption | 100% | 70% | ↓ 30% |

| Labor Costs | 100% | 50% | ↓ 50% |

Horizontal Carbonization Furnace

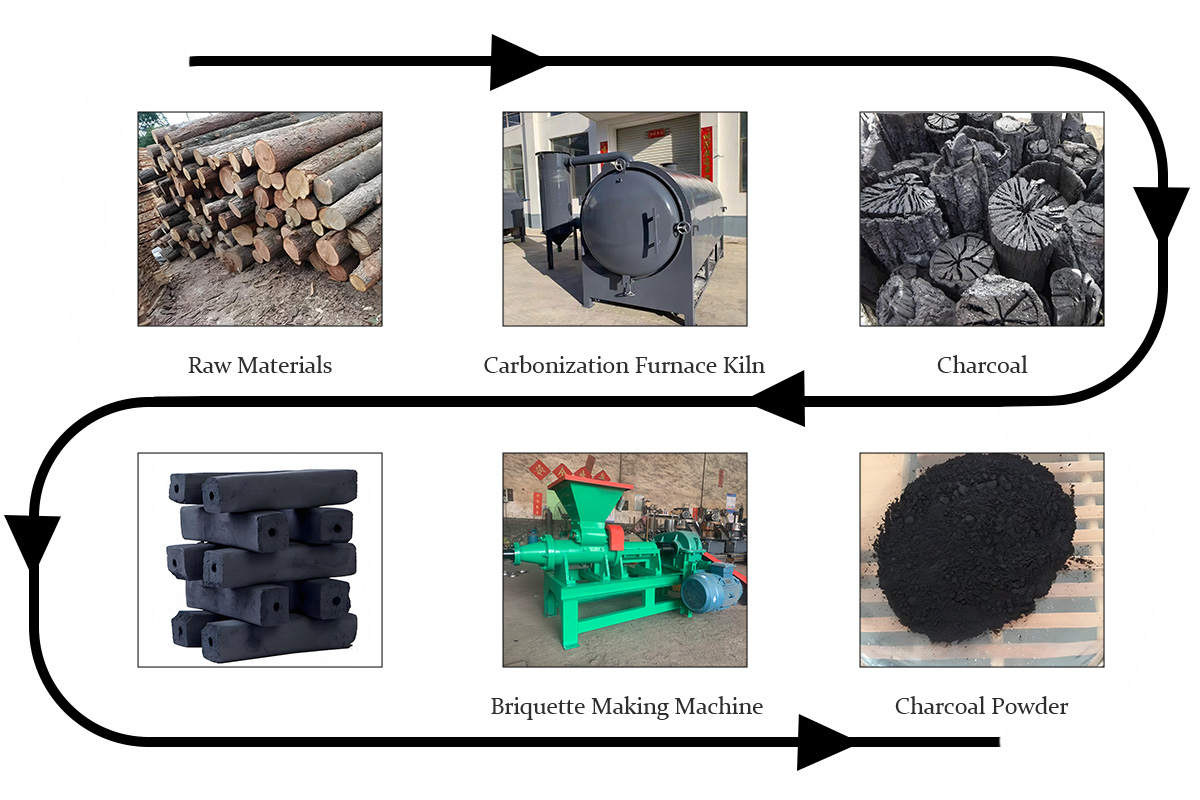

The horizontal carbonization furnace primarily operates by converting organic materials into charcoal through pyrolysis and carbonization.

Working Principle

Horizontal carbonization furnaces utilize pyrolysis to decompose materials like logs, briquettes, and bamboo stacked inside the furnace through anaerobic heating, generating combustible gases. During this process, the woody materials undergo rapid thermal decomposition, and the generated combustible gases inside the furnace are combusted through reverse low combustion. This self-sustaining combustion eliminates the need for re-ignition at the furnace bottom in later stages. Typically, the interior of the carbonization furnace contains four layers of pipes, arranged from top to bottom: preheating and drying pipes, low-temperature carbonization pipes, and high-temperature carbonization pipes. These pipes progressively increase the temperature, facilitating the release of volatiles from the materials and their subsequent combustion, ultimately yielding the desired carbonized products.

Carbonization Process

The carbonization process primarily consists of preheating, pyrolysis, and cooling stages. Once the material enters the rotary drum, heat carriers (such as hot air or gases) gradually raise the temperature through heat transfer. As the temperature increases, volatile components within the material begin to release and undergo combustion in the burner, generating thermal energy to sustain the carbonization process. Finally, in the cooling stage, the carbonized products are cooled down by a cooling system to achieve the desired end product.

Application Scenarios

Horizontal carbonization furnaces are well-suited for small-scale production, enabling efficient and high-yield continuous production of charcoal and other carbonized products. They accommodate a wide range of raw materials, including coconut shells, rice husks, nut shells, and biomass pellets, offering advantages in high throughput and automated control. Furthermore, horizontal carbonization furnaces can achieve dust-free and smoke-free operation by incorporating a flue gas recovery system. The recovered flue gas can be repurposed for heating, cooking, or supplying dryers, further enhancing their environmental friendliness.

Charcoal Making Machine Operation Demo Video

Charcoal Machine FAQ

- • Electricity/Fuel

- • Labor

- • Maintenance

• Call +86 173 1979 8686 for direct consultation

• [Online Inquiry] for quick response

Customer Testimonials

"Consistent high-carbon fuel was impossible until we adopted Hengju's furnace. Precise temperature control delivers uniformly carbonized charcoal that burns hotter and cleaner. The integrated smoke reduction system enhanced our environmental compliance, driving customer satisfaction and repeat business."

"Contrary to my expectations, the intuitive automated controls simplified operations dramatically. Tasks requiring multiple workers now need just one person. Excellent post-sale support ensured smooth implementation. Labor costs dropped 60% while efficiency soared."

READY FOR TRANSFORMATION? Automate Your Charcoal Production

Ready to boost your charcoal production? Contact us today to get a quote for our charcoal machines. Our team of experts will be happy to help you choose the right machine for your needs.